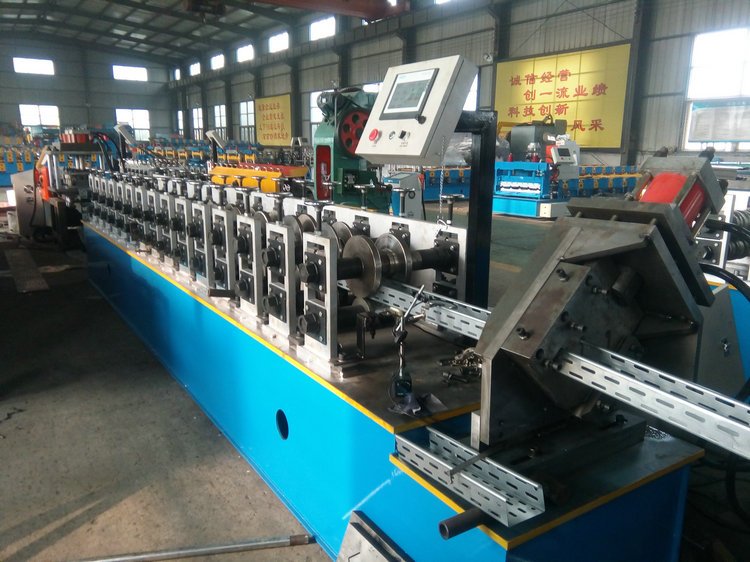

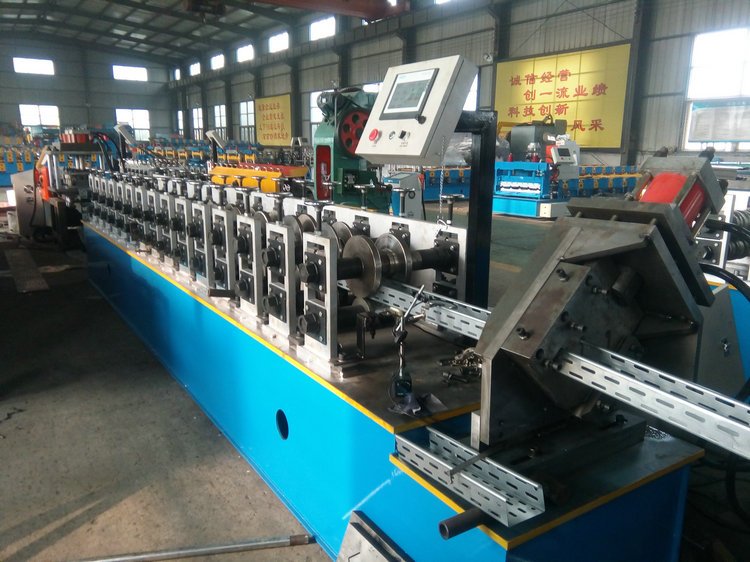

Galvanized iron perforated cable tray cold roll former

Decoiler

Max Loading:5 T

Width: 1250mm

ID: 450-550mm It is used to support the steel coil and uncoil it in a turnable way.

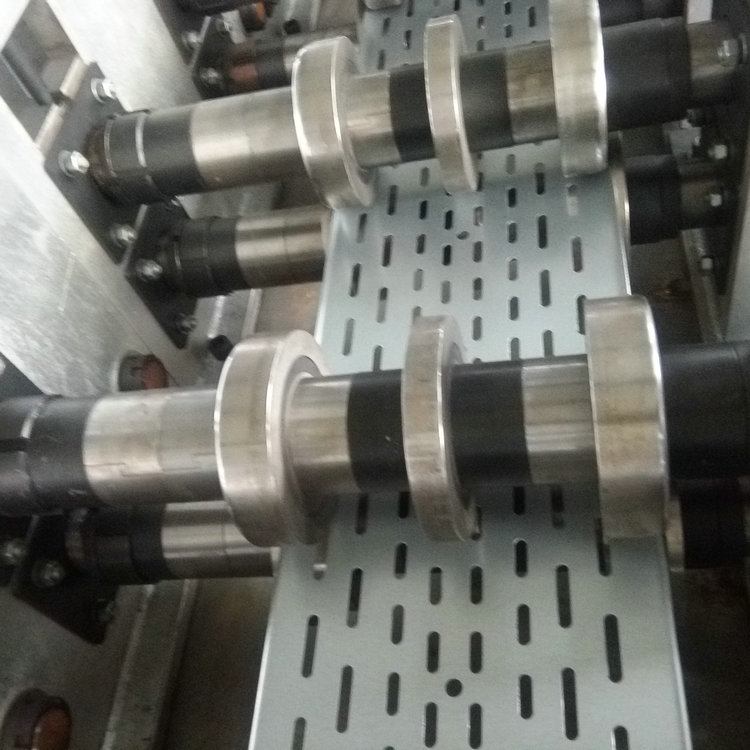

Leveling Part Put the raw material through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate iron panel.

Punching and shearing part.

Max length of cutting 10m

1. This part will punch material to the type as customer required.

2.Hydraulic punching

Material of rollers: GCr12MoV

Tolerance: ±2mm

3. Constitution can-be welded, composition need to bolt.

4. We use PLC and encoder measurements. This type is higher than the photoelectric measurement.

Roll Forming Machine Feature: Ensure the stability, accuracy and long life.

Size: 12m*1.8m*1.5m(L*W*H)

Weight: 16 Ton

Voltage: customize by customer.

Method for fixing roller: arch type.

Material of shafts: 400# I-beam

Transmission method: gear box

1). The main shaft material: No. 45 steel quenching and tempering treatment, the outer shaft diameter is90mm

2). Wheel material: quenching process of GCr15 bearing steel HRC58-60

3) Roller: 20 stations.

4). The main motor power: 22kw

5) Forming: 12M per minute.

Hydraulic Station Hydraulic oil Power: 5.5kw

Hydraulic oil type: 46#

Components: The system includes a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes. and two sets of electromagnetism valves

Electric Control System

1.Adopted PLC , transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.

2.Other electric element are Delta

3.Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety.

Counter A counter measure length, pulse and the length is determined.

OMRON encoder to measure the length.

Product Categories : Cable Tray Roll Forming Machine