Steel Corner Bead Production Equipment

Support you money !! Support you service !! Support you technology !!

PLC control system !! Hydraulic cutting system !! Mult-language conversion system !!

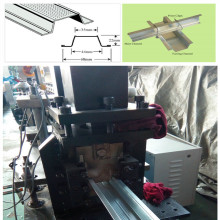

Galvanized metal light Steel Angle Machine is a strip of raw materials, through continuous cold rolling molding, production of complex cross-section profiles, which consists of decoiler, guide rack, forming hosts, calibration device, cut-off part, receiving station , composed of electrical control and so on.

Steel Corner Bead Production Equipment Technological process: Uncoiler-feeding system-Roll Forming Machine-cutting system-table

Steel Corner Bead Production Equipment Uncoiler system: Usage:It is used to support the steel coil and uncoil it in a turnable way. Passive uncoil pulled by roll forming system. Loading capacity:1500kg Uncoiling width:300mm Inner diameter: 450-550 mm

Steel Corner Bead Production Equipment Main Roll Forming System: Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission ,roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is being stamped. Length of the main part: about 3000 х800 х1400 Weight of main part: 3000kg Voltage : 380 V/50HZ 3Phase or as your required Roller fixer : middle plate Frame : 450 H steel welded Drive mode: gear Material of rollers:GCr12MoV, surface hard chromium plating. Material of shafts: 45# steel with tempering Diameter of shafts: φ 40mm Number of rollers : 10 rollers

Main power: 3 kw

Steel Corner Bead Production Equipment Shearing Mechanism: Function : Automatic cutting controlled by PLC It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. Material of blades: Cr12 quenched Power supply : hydraulic power Components:It contains one set of blade , one hydraulic tank and one cutter machine.

Steel Corner Bead Production Equipment Hydraulic Station: It is controlled by gear pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job. Power: 5.5 kw Hydraulic oil: 46 #

Steel Corner Bead Production Equipment Electric Control System:

1. Adopted PLC , frequency converter , Delta touch screen from Taiwan to ensure high speed with stability, precision and lifetime. 2. Other electric element are Panasonic

Steel Corner Bead Production Equipment Warranty:

1. We will provide technical support for the whole life.

2. Installation & adjustment : We can take a vedio for the customer and the customer can also come to our factory, we can train customer how to installation and adjustmentthe machine.

3. Oversea service: the buyer should charge of visa, return ticket, food and accommodation overseas and USD50/person/day salary.

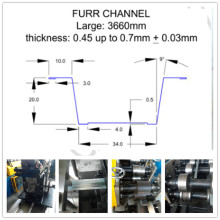

Product Categories : C/U/ Channel & T Bar Roll Forming Machine > Ceiling Channel Roll Forming Machine