galvanized aluminum metal corrugated steel

sheet roll forming line Roofing Panel machine

Corrugated sheet are widely used in building: the steel-structured large-scale warehouses, plants, supermarkets,

shopping malls, trade markets, stadiums, holiday villages, sanatoriums, hotels, villas, residences, and

different kinds of greenhouses. What's more, equipment can be designed and manufactured as customers'requests.

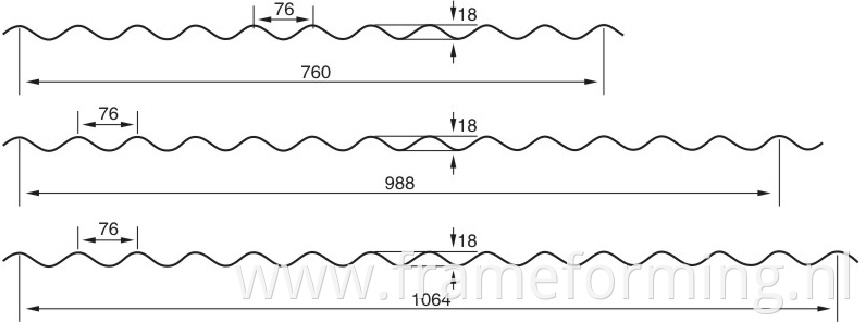

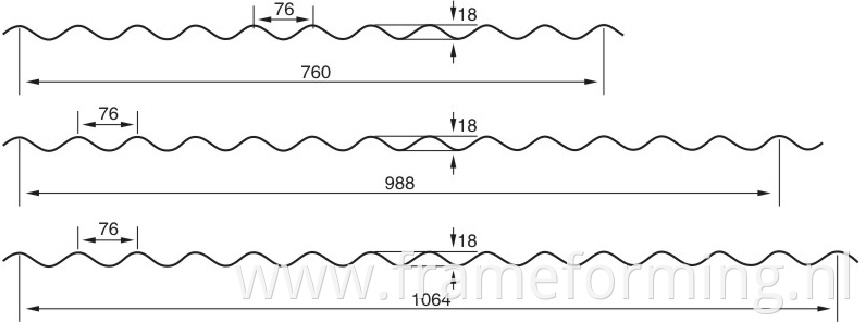

Production parameters

Processing material: colored steel plate, galvanized plate, or aluminum plate

Material thickness: 0.3- 1.2mm

Material width:1220mm/1200/1000/1250

Forming speed: 8-25m/min

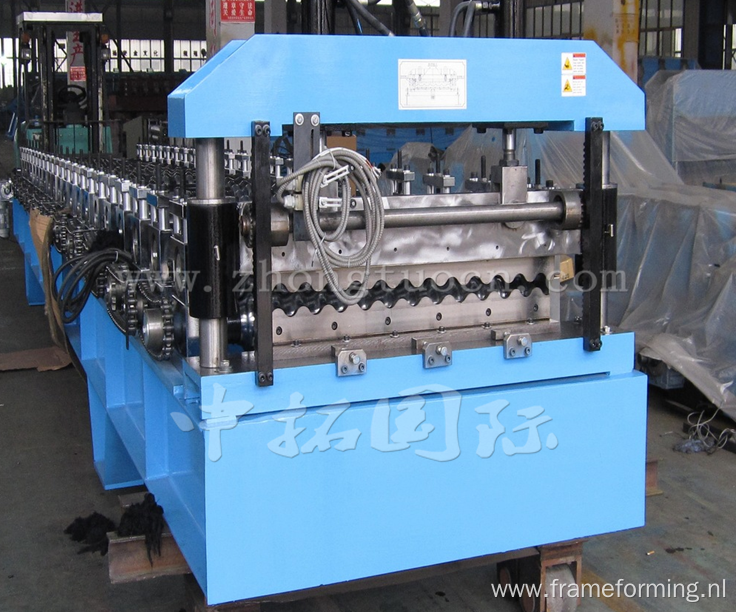

Description of Corrugated Roof Sheet Making Machine

This kind of Corrugated Roof Sheet Making Machine used in simple house, steel plants and other wall board production.The maximum speed can be 45 m/min,greatly improving the production efficiency.The finished corrugated sheet are widely used in some temporary construction as wall or roof panel,for example .The sheet or panel of corrugated roofing machine is light as well as low cost but high strength, short building period, and re-cycle use.

Specification of Corrugated Roof Sheet Making Machine

Material Type:GI/PPGI/AL

Material width:914/1000/1200/1220/1250 mm(customized)

Material Thickness:0.3-0.8 mm

Sheet length: Any length

Working Speed:8-25 m/min (10 piece per min as 8 feet per piece,standard machine)

Control System:Mitsubishi/Siemens PLC& transducer(customized)

Total Power:About 8.5 kw

Total Weight:About 6 T(up to the final design)

Un-coiler System

Usage: It is used to support the steel coil and uncoil it in a turntable way..Passive uncoil pulled by roll forming system

Loading-capacity:5 T

Uncoiling-width:1000/1200/1250 mm

Inner-diameter: 450-550 mm

Entry Beach of Corrugated Roof Sheet Making Machine

Usage:Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat,

parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate panel.

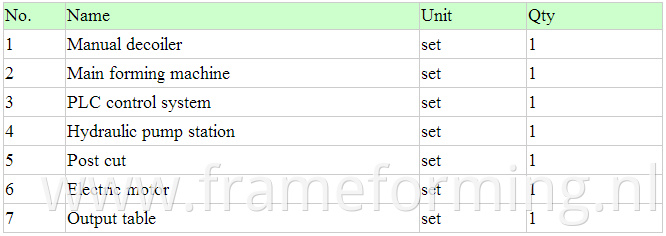

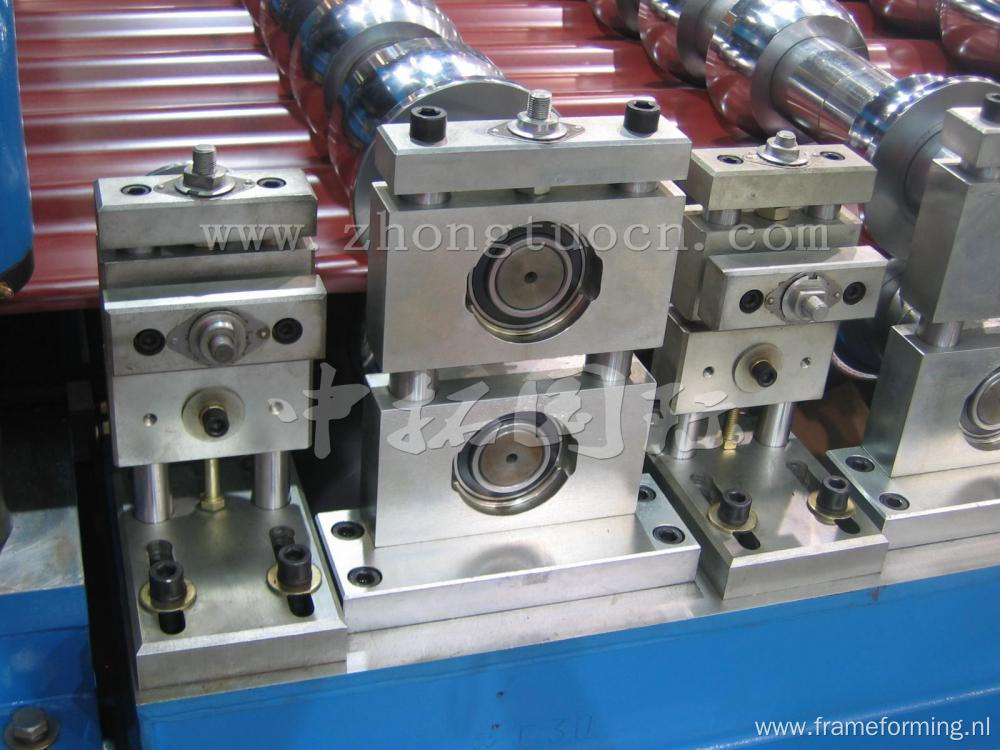

Main Roll Forming Machine

Usage :In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission,

roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Frame : 350 H steel

Drive mode: chain

Material of rollers:45# steel, surface hard chromium plating.

Length of the main part:8650*1650*1500 mm

Voltage:380 V/50 HZ 3 Phase

Roller fixer : middle plate

Material of shafts: 45#steel

Diameter of shafts: 80 mm

Number of rollers : 18 rollers

Shearing Mechanism of Corrugated Roof Sheet Making Machine

Usage :It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Function: Automatic cutting controlled by PLC.

Material of blades: Cr12 quenched

Power supply : hydraulic power

Hydraulic Station of Corrugated Roof Sheet Making Machine

Usage :It is controlled by gear pump. After filling the hydraulic oil into the hydraulic oil tank, the pump drives the cutter machine to begin the cutting job.

Components: The system includes a set of hydraulic tank, a set of hydraulic oil pump, four hydraulic pipes. And two sets of electromagnetism valves.

Power: 4 kw

Hydraulic oil

: 46#

Electric Control System

Feature:

Adopted PLC, frequency converter, Delta from Taiwan to ensure high speed with stability, precision and lifetime.

If you need, we can change it other brand or little computer type for touching screen.

Product Categories : Roofing Sheet Roll Forming Machine > Corrugated Roof Roll Forming Machine