What is the application of corrugated roof panel roll forming machine?

corrugated roof panel roll forming machine

is mainly producing steel roof/ wall sheet .The final products have teo types,corrugated sheet and trapezoidal sheet.As we know, steel roof/ wall sheet is widely used in large span factory building, warehouse, office buildings, villas, roof, cold storage, air purification room, stores, kiosks, and temporary housing.

What is the advantage of corrugated roof panel roll forming machine?

1.The system is easy to operate and use. PLC: Delta(Can customize as customer require)

2.the surface of the final product is very smooth and beautiful without any scratch on the surface.

3.customized:design the machine according to your specification and profile drawing.(for your reference)

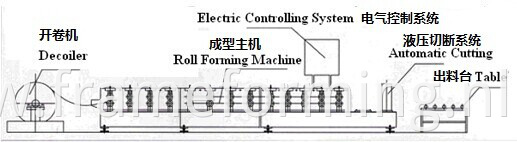

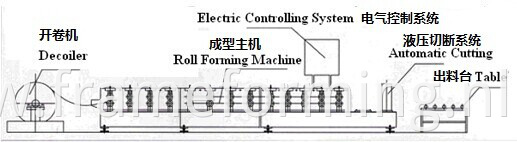

Processing flow diagram of Roofing Sheet Roll Forming Machine

Technical parameters of corrugated roof panel roll forming machine

Decoiler

The thickness of the raw material (steel plate) can be 0.3 - 0.8 mm.The loading capacity can reach 3T . It is used to support the steel coil and uncoil it in a turntable way.

Uncoiling width: 500mm

Inner diameter: 450-550mm

Main roll forming machine:

Roller fixer : Guide column

Speed: 5-50m/min

Material of rollers: GCr12MoV

Material of shafts: 45# steel with tempering

Diameter of shafts: φ40mm

Shearing Machine:

Material of blades: Gcr12 quenched

Power supply : hydraulic power

Frame : Pillar style with rack

Electic Control System:

1. Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.

2. Other electric element are Delta

packing :

1. One 20ft container for loading one set corrugated roof panel roll forming machine with Manual Decoiler.

2. The whole wiped anti rust oil ,PLC controller covered by foam film.

3. Spare parts and some small parts packed in plastic tooling box.

4. All components of Deck Roll Forming machine fixed by steel wire.

our services

1. Installation and training:

a.If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also train your workers/technician face to face.

b.Without visiting, we will send you user manual and video to teach you to install and operate.

C.If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary things.

2. After Service of stud and track cold roll forming construction machinery

a.One year guarantee for whole machine.

b.24 hours technical support by email or calling

c.If there is any problem found of the machine, we will repair it for free in one year.

Product Categories : Roofing Sheet Roll Forming Machine > Corrugated Roof Roll Forming Machine