Door Channel Forming Machine:

Metal door frame machine is a kind of Roll Forming Machine which is developed to make various types metal door or window frames, reinforced, fire stop doors, etc by roll forming method. By this one metal door frame roll forming production line, you can finish roll forming, cutting end connection part and others. After roll forming by our production line, we could make very smooth and beautiful metal door frame without any scratch on surface. This metal door frame production line is composed by the following elements: De-coiler, feed & leveling device, main roll forming machine, cutter, run-out table, etc. Those machines are customized according to the drawing profile of metal door frame.

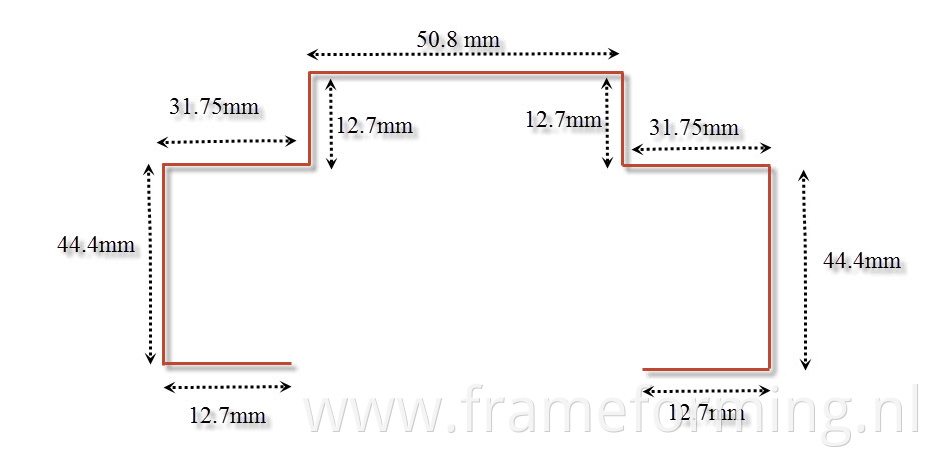

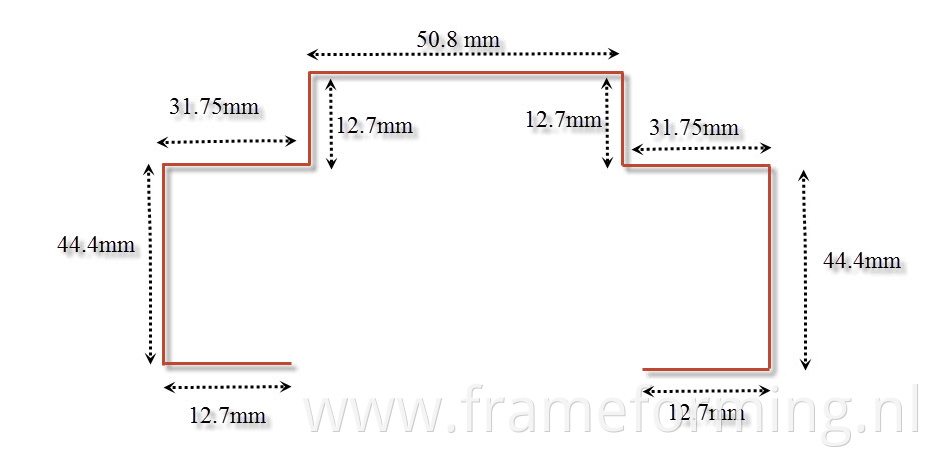

Profile drawing :

We can do all kinds of metal door frame,just you send us the profile drawing, we will design the door frame machine according your demand.

The production Process:

De-coiler----Feeding and Leveler---Roll Forming---Cutting Part---Run-out Table

Composition of Door Channel Forming Machine:

1. De-coiler

Usage: It is used to support the steel coil and uncoil it in a turntable way..Passive uncoil pulled by roll forming system

Loading capacity:1.5T

Uncoiling width:300mm (according to the profile drawing)

Inner diameter450-550mm

2. Feeding and Leveler

Usage: Put the raw material(steel plate) through the beach to manufacture and process,it can guarantee that the products are neat, parallel and everything is uniformity.Please refer to the equipment regulation to know the function of locate angle iron.

3. Roll Forming for metal door frame

Roller material :45# steel, surface hard chromium plating.

Shaft material : 45# steel with tempering

Outer diameter of shaft :70mm

frame : 400H steel

Voltage: 380v,50Hz,3 phase As customer`s need

Dimensions:15400 * 1800 *1800mm Final size depend on the design

Main power: 8.5-15kw Depend on the thickness of material and size of machine

Forming steps rollers: 12-20 stations Final rollers depend on the design

Speed :8-15m/min

4.Cutting Part

Cutting system: adopt advanced hydraulic cutting system, automatic cut after forming no distortion, waste, high safe factor(main motor stops and then cuts).

Cutting type: stop machine cutting.

Function: Automatic cutting controlled by PLC.

Material of blades: Cr12MoV steel with quenched treatment 60-62℃

Power supply : hydraulic power

Hydraulic Station

Usage :It is controlled by gear pump. After filling the hydraulic oil into the hydraulic oil tank, the pump drives the cutter machine to begin the cutting job.

Components: The system includes a set of hydraulic tank, a set of hydraulic oil pump, four hydraulic pipes. And two sets of electromagnetism valves.

Power: 4 kw

Hydraulic oil: 46#

Electric Control System

1.Adopted PLC, frequency converter, Delta from Taiwan to ensure high speed with stability, precision and lifetime.

If you need, we can change it other brand or little computer type for touching screen.

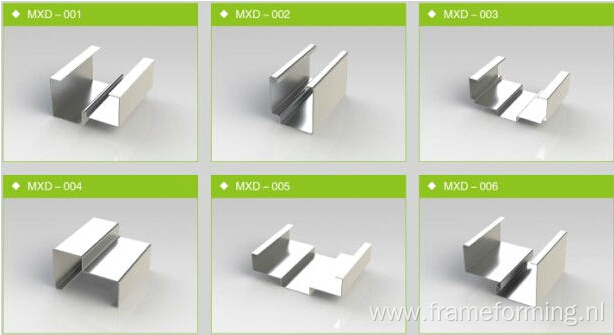

Sample of metal door frame :

Product Categories : Door Frame Roll Forming Machine