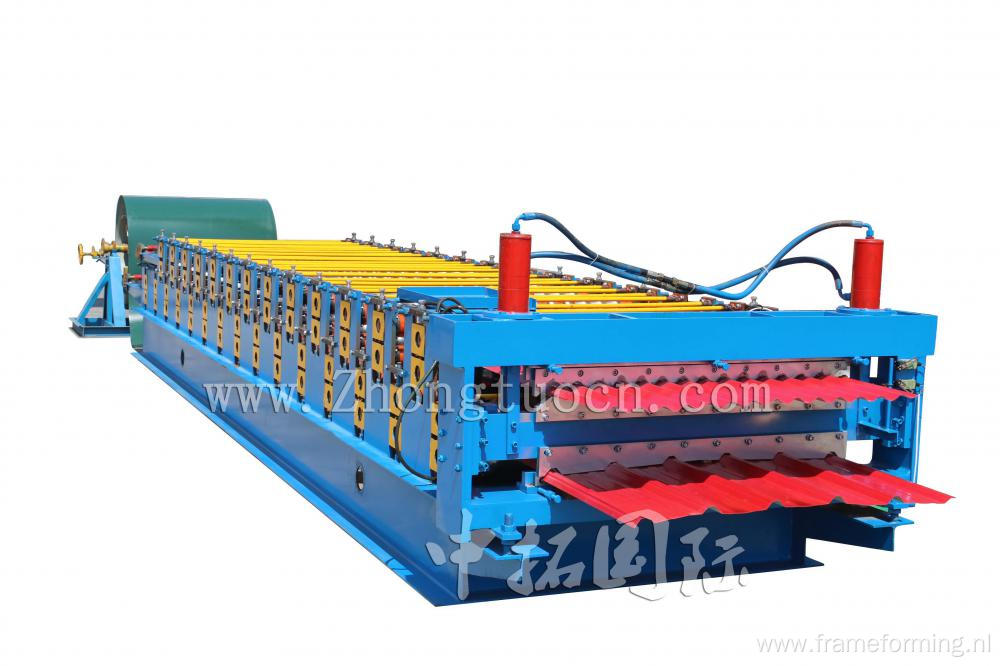

Cold Double Layer Corrugated

Roofing Sheet Machine

| Machine Description | Qty | Delivery time | Container Type | Price (FOB TIANJIN) |

| Double layers Roll Forming Machine | 1 SET | 45 working days after receiving deposit | One 40GP | USD 13400 |

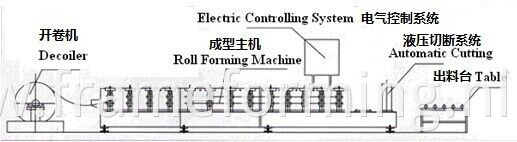

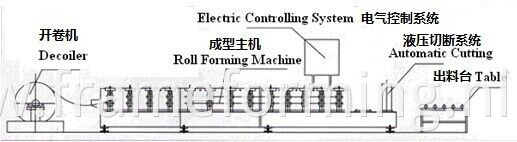

Production process

Uncoiling→Feeding material into machine→Roll forming→Measuring length→ Step formed→ Auto cutting→Products receiving

Forming device

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission,roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is working

Feature : Ensure stability , precision and lifetime.

| No. | Main parameter |

| 1 | Length of the main part | About8500х1650х1500mm |

| 2 | Weight of main part | About 5.5 t |

| 3 | Voltage | 380V/50HZ3Phase (as customer`s request) |

| 4 | Roller fixer | Middle plate welded |

| 5 | Frame | 350 H steel welded |

| 6 | Frame thickness | 16mm |

| 7 | Drive mode | Chain |

| 8 | Material of rollers | 45# steel, surface hard chromium plating. |

| 9 | Material of shafts | 45# steel |

| 10 | Diameter of shafts | Φ80mm |

| 11 | Number of rollers | 15 rollers |

| 14 | Main power | 5.5kw |

Cutting device

Advanced hydraulic drive, automatic punching and cutting after forming, no distorting or wasting, high level safety factor.

(include cutting tools, hydraulic tank, cutter machine)

| Blade Material | Cutting system |

| Cr12 quenched | Full automatic |

Counter

One counter gauges length, pulses, and decides length. Omron encoder for length measurement.

Un-coiler System

Usage: It is used to support the steel coil and uncoil it in a turntable way.

Passive uncoil pulled by roll forming system

| Loading capacity | Uncoiling width | Inner diameter |

| 5T | 1220mm | 450-550mm |

Coil feeding part

Usage: Put the raw material(steel plate) through the beach to manufacture and process,it can guarantee that the products are neat, parallel and everything is uniformity.Please refer to the equipment regulation to know the function of locate angle iron.

Products receiving tables

1. It adopts welded steel and supported roller to transmit the products.

2. 3*0.9*0.6m

Controlling device

1.Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with

stability, precision and lifetime.

2.Other electric element are Delta

3.Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety.

| Screen | PLC |

| Text screen displayer | Taida DVP14ES from Taiwan |

Components of production line

| No. | Name | Unit | Qty |

| 1 | Manual Decoiler | set | 1 |

| 2 | Main forming machine | set | 1 |

| 3 | PLC control system | set | 1 |

| 4 | Hydraulic pump station | set | 1 |

| 5 | Post cut | set | 1 |

| 6 | Electric motor | set | 1 |

| 7 | Output table | set | 1 |

Production parameters

Processing material: colored steel plate, galvanized plate, or aluminum plate

Material thickness: 0.3- 0.7mm

Material width:1220mm

Forming speed: 12m/min

Product Categories : Double Layer Roll Forming Machine