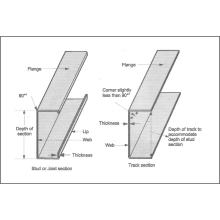

Steel CW UW Machine Metal Tracks Roll Forming Machine

Zhongtuo Steel CW UW Machine Metal Tracks Roll Forming Machine offer builders a competitive alternative to traditional wood trusses.This machine provides significant improvements over other Double Furring And C Channel Machine currently available. Flexibility and design advantages allow architects, engineers, contractors and owners' exceptional versatility and performance characteristics not available with any other type of truss material.Our machine could update with the fashio for providing new design increases material efficiency, ease of fabrication, simplicity of erection, and improved safety of material handling. Nomatter for running business or for big construction, this machine will be good helper for you.

The component of Steel CW UW Machine Metal Tracks Roll Forming Machine :

1.Decoiler

2.main roll forming machine

3.punching maching(as customer's need)

4.Cutting machine (normal cutting and flying track cutting saw)(as customer`s need choose one set)

5.PLC control

6. Steel CW UW Machine Metal Tracks Roll Forming Machine Counter

7.hydraulic station

8. receiving table

Some main parameters of Steel CW UW Machine Metal Tracks Roll Forming Machine :

1.Working efficiency:15-50m/min

2.Processing material: GI or others

3.Material hardness: 550MPA-350MPA

4.Thickness of material: 0.4-1.5mm

5.Width of material: as you need

6.Un-coiler system: 1.5 -3 T Ton decoiler (Manual Decoiler, electric decoiler , hydraulic decoiler)

7.Number of rollers: 12 rollers

8.C Steel Roof Purlins Roller fixer: guide column

9.Roller material: Gcr12 MoV quenched

10.Material of shaft: 45# steel

11.Diameter of shaft: 40mm

12. Main power: 3KW

13.Hydraulic power: 3KW

14.Hydraulic pressure: 20Mpa

15.Blade material:Gcr12 MoV quenched

16.Voltage: 380V, 50HZ, 3phase (adjustable by customer)

17. Double Furring And C Channel Machine Frame thickness: 25mm

18.Drive : gear, chain or case of different speeds(as customer`s demand)

19.Punching machine: Gcr12 MoV quenched

20.Double Furring And C Channel Machine Control system: Delta of Taiwan, or as you need.

21.Double Furring And C Channel Machine color: yellow or blue

22.Lenth: 3000*800*1400mm

Payment: 30% T/T in advance and balance 70% after inspection confirmation before shipment.

1. One year, and we will provide the technical support for the whole life.

2. Training: the buyer should charge of visa, return ticket, food and accommodation overseas and

USD50/person/day for salary.

3. Need one technician.

4. Training time: one week (contains the time of installation and adjustment)

Othe machines:

Product Categories : C/U/ Channel & T Bar Roll Forming Machine > Drywall Profile Roll Forming Machine