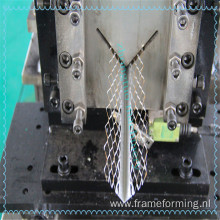

Corner bead profile machine can make corner beads in batch. The corner bead making machine can be customized according to your finished product or drawing profile. According to the real needs, there are many different design. Here I show some examples for your reference:

Wall angle bead are often called corner beads in the construction trade. They may typically be seen in 8-foot (about 2.4-meter) lengths, which is a standard wall height in the US. Angle beads are only used on exterior corners and are not used on interior corners. Builders typically use drywall tape - which is made from a flexible, mesh material - to join the inside corners of walls.

The features of corner bead:

1. The metal corner bead is made of high quality galvanized material on both sides to prevent aging, corrosion and fire, and effectively prevent rust.

2. The precise acute angle dimension design of the metal corner strips avoids the concentrated stress when the corners are impacted, and evenly distributes the external forces to the peripheral edges, effectively protecting the sunken corners from damage.

3. Two types of metal corner strips, punching and expansion, not only facilitate nailing but also make the gypsum board or other adhesive materials in the corner strips more firm.

4. The construction of metal corner strip corners does not rely on wood strips. Primary plasterers can also make perfect corner lines, shorten construction time, and effectively reduce construction costs.

Some elements of the wall angle bead roll forming machine:

Decoiler

Usage: It is used to support the steel coil and uncoil it in a turntable way.

Passive uncoil pulled by roll forming system

Loading capacity: 1.5 T

Uncoiling width: 300mm

Inner diameter: 450-550mm

Punching system:

Main roll forming machine:

Length of the main part: about 3500х800х1400 Weight of main part:3 tons

Voltage : 380V/50HZ3Phase (as customer`s request)

Roller fixer : Guide column

Frame : middle plate welded

Memorial arch frame type

Frame thickness:20mm

Drive mode: gear

Material of rollers: GCr12MoV

Material of shafts: 45# steel with tempering

Diameter of shafts: φ40mm

Number of rollers: 9 rollers

Main power: 3 kW

Cycloidal planetary gear speed reducer)

The different sizes can be produced on this machine

by adjusting the feeding width.

For the real use of the wall angle beads, here is some information for your reference:

Stainless Steel extended wing (64mm) angle nead for external rendering applications. Suitable for 16-20mm render depth. Available in 3.0m lengths - 25 lengths per carton.

Product Categories : C/U/ Channel & T Bar Roll Forming Machine > Drywall Profile Roll Forming Machine