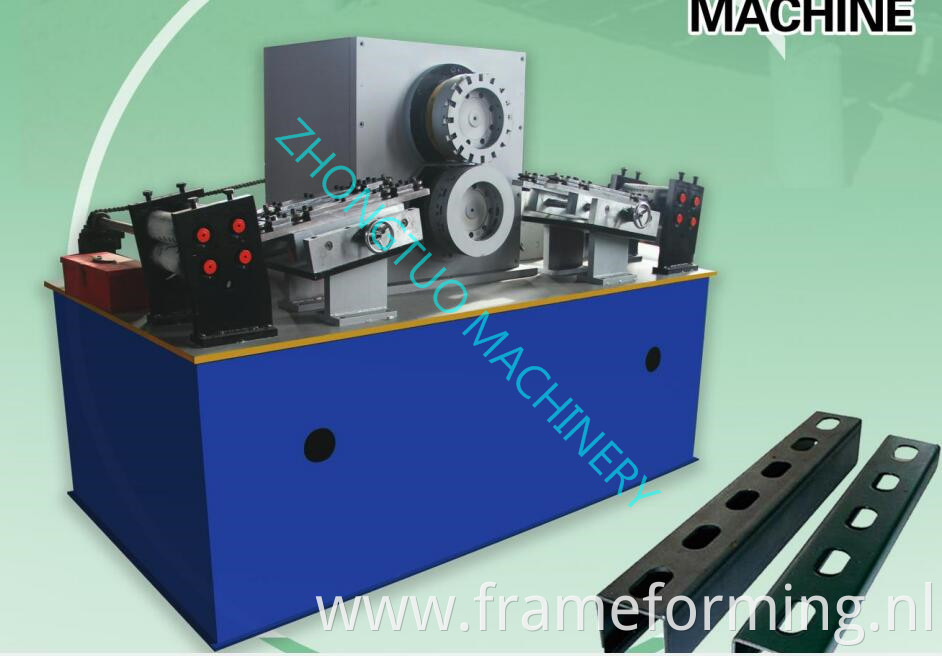

High speed rotary punching machine

Why Zhongtuo research and develop rotary punching machine?

1. Traditional punching machine is huge in size; it takes up big space in the factory. In morden society, factory size is limited as the price up of landing. The rotary punching machine size is just a quarter of the traditional one.

2. Now worker salary up, so manufacturer wants to in limited 8 hours to make more finished product. So speed is what we are pursuing. The rotary punching working speed could reach 100m/min. It is 4 times than the traditional one.

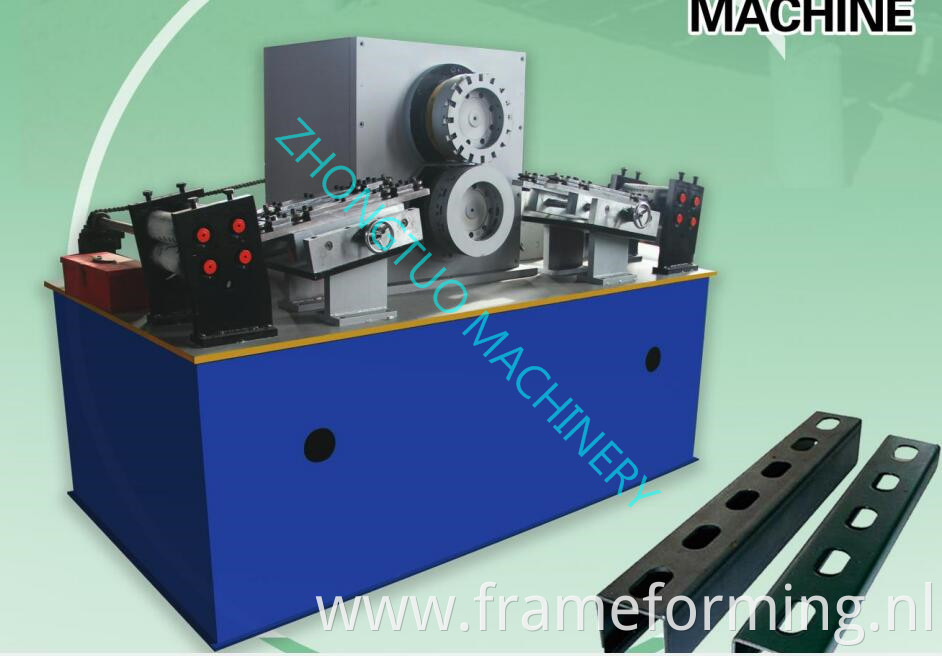

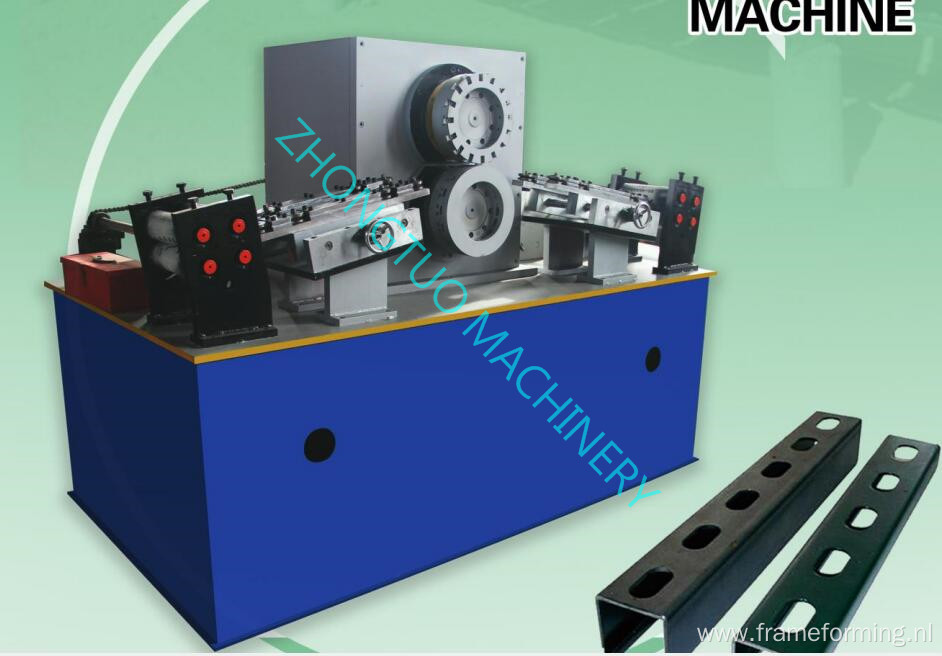

Meanwhile there are more reasons to make us develop it, in the following part, I will share more details. First check the rotary punching machine pictures:

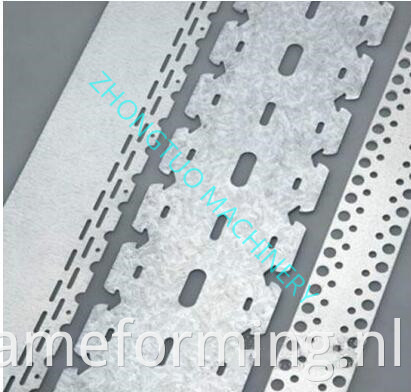

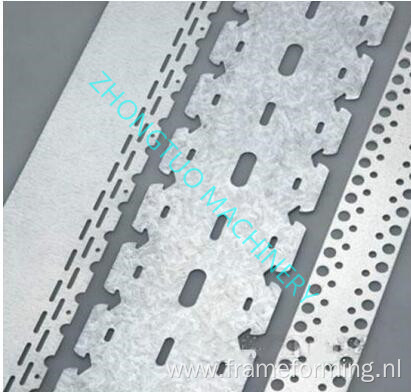

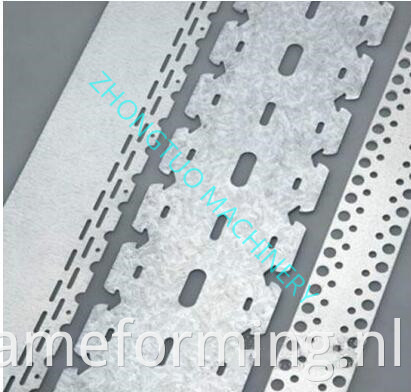

What kind of punching types this rotary punching machine could process?

1. Support Coil material thickness : 0.4mm- 3 mm

2. Feeding width :≤500 mm

Here are some punching samples for your reference:

High speed rotary punching machine rollers parameters for your reference:

1. Roller material: 40Cr

2. Pairs of forming rollers: 8 sets

3. Chains transport: Gear transmission

4. Forming speed: 80-100meter/min

5. Main motor power:5.5kw

6. Punching head is changeable.

Features of high speed punching machine:

1. High speed punching

2. One machine supprts many types of punching molds.

3. Small in size, beautiful in appearance.

4. Long time to use

5. Punching accrate and shape is sharp.

6. Have waste coil collector, it is easy to get together the punched wasted coil

7. It could be used together with any type Roll Forming Machine which needs punching holes.

8. Electricity is adjustable according to customer request.

9. Save energy and fully automatic

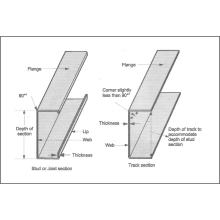

Product Categories : C/U/ Channel & T Bar Roll Forming Machine > Drywall Profile Roll Forming Machine