Wall angle and L shape roll forming machine is same like other roll forming machines, it can make the wall angle beads in batch. Noramlly speaking, we only use Max 0.8 for ceiling or drywall. But sometime for house frame or others, we need to make more thicker wall angle like up to 3.5mm.

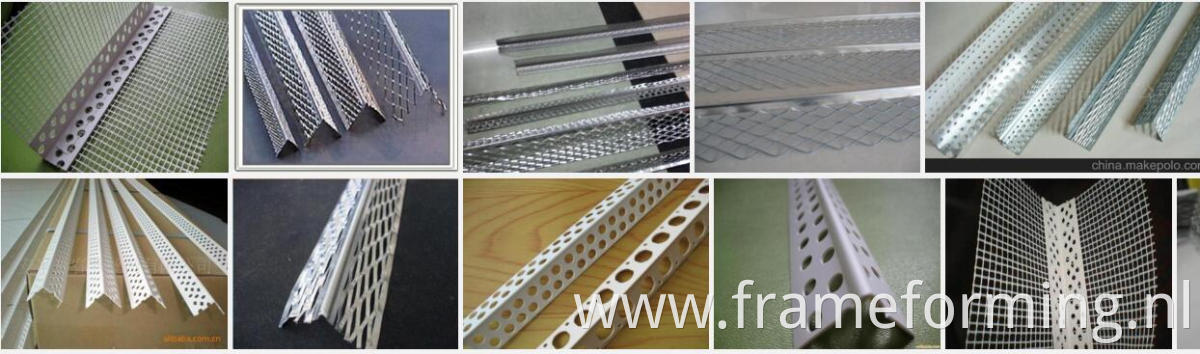

When come to this, the following machine will be helpful for you. Here I show some examples for your reference:

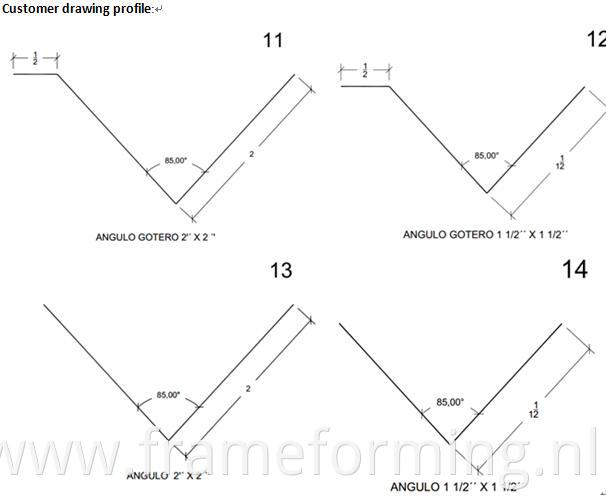

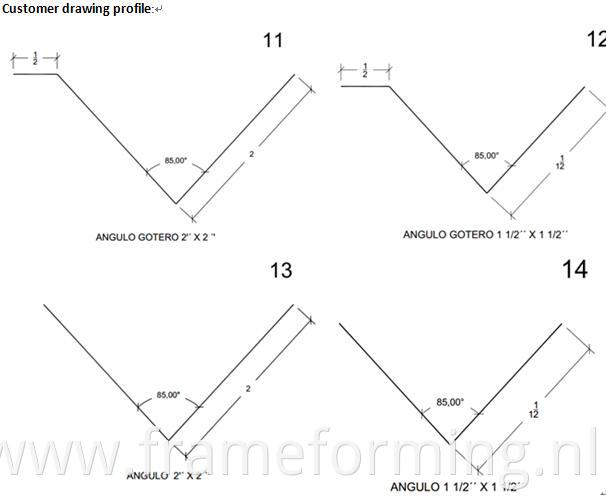

All those drawing profiles could be made by one machine. And if you need more within some range, all could be done by one machine, just you need to adjust the input coil width.

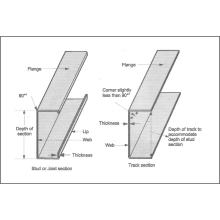

For the wall angle machine and L shape rolling forming machine, here are some parameters for your reference:

| Note: from drawing profile 11 to 12, we will use one type of roller which is something like spacer but much bigger than spacer, to adjust the sizes. For the drawing profile 13 to 14, you do not need to adjust anything, just put the coil at the center of the input coil leveling beach that is enough.So all above drawing profiles could be made by one machine. |

| Main elements of the machine roll forming machine |

| Decoiler | Usage: It is used to support the steel coil and uncoil it in a turntable way. Passive uncoil pulled by roll forming system

Loading capacity: 1.5TUncoiling width: 300mm Inner diameter: 450-550mm |

| Feeding and leveling | This part will level coil to make sure it is neat clean and straight. Meanwhile the roller will punch dots at both side of the C channel. |

| Main Machine | Size: 4300х800х1400Weight t: 2.8 tons Voltage:380V/50HZ3Phase(as customer`s request) Roller fixer : Guide columnFrame : middle plate welded Memorial arch frame typeFrame thickness:25mm Drive mode: gearMaterial of rollers: GCr12MoV Material of shafts: 45# steel with tempering Diameter of shafts: φ50mm Number of rollers :9 rollers Main power: 5.5kw Cycloidal planetary gear speed reducer |

| Punching hole and punching logo | This part will help you press your company logo on the finished products. Power: hydraulic |

| Shearing Machine | Material of blades: Gcr12 quenched Power supply : hydraulic power Frame : Pillar style with rack & pinion system Stroke switch : non-contact photoelectric switch We will give 9 pieces of cutting balde for you to change to fix those different drawing profiles. |

| Hydraulic Station | Hydraulic motor Power: 4kw Hydraulic oil: 46# Components: The system includes a set of hydraulic tank, a set of hydraulic oil pump, and two hydraulic pipes. And three sets: one is for punching hole; one is for printing words and one for cutting. Sets of electromagnetism valves. |

| Electric Control System | Feature: 1. Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime. 2.Other electric element are Delta 3. Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety. |

| Runout table | It adopts welded steel and supported roller to transmit the products. |

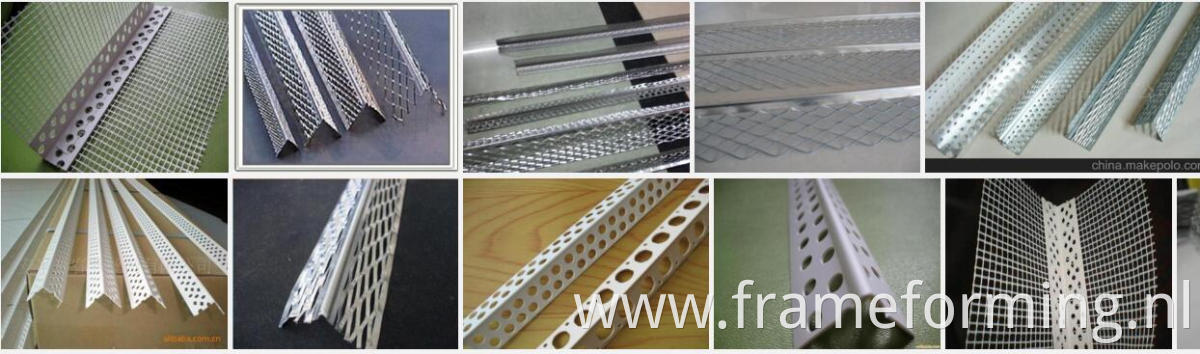

For the wall angle or L shape, if you want to make with punching holes, you just need to add one more punching machine and one more servo coil feeder. The following are some pictures for your reference.

Product Categories : C/U/ Channel & T Bar Roll Forming Machine > Drywall Profile Roll Forming Machine