Metal cap rail omega channel machine cap rail Roll Forming Machine

The Metal cap rail omega channel machine cap rail roll forming machine can produce different shapes and sizes of the metal cap rail, the metal cap rail is used as a building material channel in the steel house. it is used for the ceiling building. The metal cap rail is used with the ceiling sheet.

there are different sizes metal rail channel, one machine can make different sizes of the rail by changing the mold.

below is some details of one metal cap rail machine:

Below is some detailed specification of the metal cap rail roll forming machine.

one whole roll forming machine line including below parts:

1 decoiler, there are manual de-coiler, electric decoiler, hydraulic decoiler

2 the roll forming machine body, we deisign the machine with pillar structural, so it is convenient to change one mold to another mold.

3 Cutting, the hydraulic cutting, this cutting method is convenient and cutting without any furr.

4 Finished products receiving table, there are manual receiver and automatic receiver.

5 The PLC controlling, the machine is automatic running, and controlled by the PLC, so your worker can only press the button when operate the machines.

6 Hydraulic station, this station function is to offer the cutting power.

7 Some spare parts for the machine line , sending to you in case any parts are broken.

The machine picture is for your reference

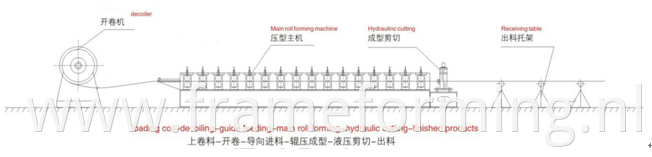

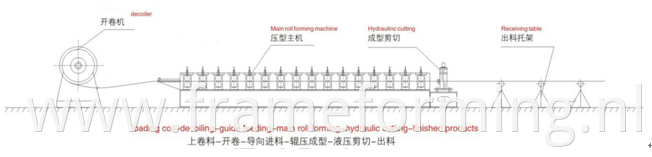

Processing flow diagram of machine

Manual Decoiler→ Feeding material into machine →Roll forming machine →Measure length→Hydraulic cutting →Finished Products

Machine pictures for your reference

1.Technical parameters

| Configurations | manual decoiler, guiding platform, main machine of roll forming, cutting device, electric motor, hydraulic station, Delta PLC control system, run out table |

| |

| Material | Raw material | Galvanized |

| Thickness | 0.3-0.8 mm |

| |

| Manual decoiler | Inner Diameter | 450-550mm |

| Outer Diameter | max 1500mm |

| Max Coil width | 500mm |

| Capacity | 3T |

| |

| Main Forming Machine | Forming steps | 12 rollers |

| Shaft diameter | 40Cr steel with quenched treatment, precision machined, outer diameter: 40mm |

| Design type | Guide column |

| Machine frame | Memorial arch |

| roller material | bearing steel with quenched treatment |

| shaft material | 45# steel with tempering |

| Work speed | 20-60m/min |

| Transport | reduction gearbox transmission |

| Changing size methods | Completely changing the mold linear system |

| Structure | independent stand |

| Power of main machine | 7.5 kw |

| Type of cutting and punching | Hydraulic |

| Cutting tolerance | ±1mm |

| Blade and punching material | GCr12MoV quenching treatment 58-60° |

| Cutter quantity | 1 set |

| Working pressure | 20MPA |

| Cutting system | Hydraulic servo tracking cutting | the machine is with servo tracking cutting, the cutting knife can move automaticly with the speed of the machine. so that, the tracking cutting can keep same speed with the main forming speed, and cut the finished products without any stopping. |

| 2. Automatic tracking cutting | No. | Name | Size and mode | number | note | | 1 | base frame | 100*100*6 | 1 | | | 2 | Control station | | 1 | Include switch button | | 3 | Hydraulic station | 4kw | 1 | | | 4 | Oil pump | 63*80*80 | 1 | | | 5 | Cooling device | 35Hz | 1 | | | 6 | Sensor | Npu | 2 | | | 7 | Encoder | 600 | 1 | Omron | | 8 | tachometric wheel | | 2 | | | 9 | Servo motor | 3.9kw | 1 | GSK | | 10 | Mold | Mulfan1 | 4 | | | 11 | Lead screw | Sfu4020-1230 | 1 | Taiwan | | 12 | Guide | HG35-2000 | 2 | | | 13 | Slider | HGH35cA | 4 | | | 14 | Coupling | | 4 | | |

| |

| Control Device | PLC Control | Speed regulation control cabinet |

| PLC language | As required |

| Touch screen | Delta |

| Function | Automatic length and quantity measurement |

| |

| Other Spare part | Weight | About 8.0 ton |

| Dimension | 6800*1800*1500 (mm) L x W x H |

| Main body color | As required |

| Voltage | 380v, 50Hz,3 phase(or as required) |

| Spare cutting blade | One piece for one size |

If you need this machine, we can design the machine and send you an offer

we need some details to design the machine:

1 The profile drawing of the cap rail channel

2 The thickness of the cap rail

3 The material of the cap rail

4 The working speed of the cap rail channel roll forming machine

you can contact me by below details:

Product Categories : C/U/ Channel & T Bar Roll Forming Machine > Drywall Profile Roll Forming Machine