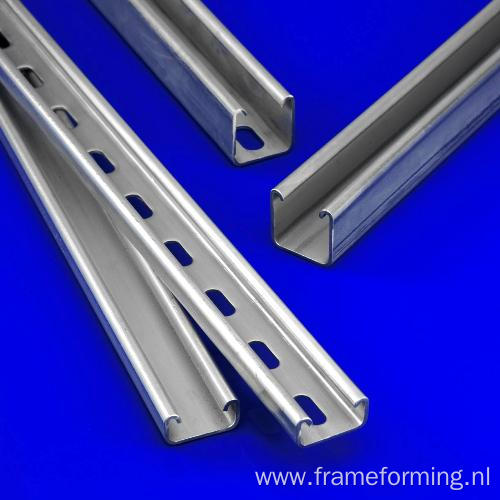

The solar strut channels are used to make the structure of the Solar Panels, our Steel Strut Channel Roll Forming Machine produce all size of strut channel required for this purpose.

The solar strut channel forming machine is compact in shape and size to fit in any workshop and start the production. It is easy to operate and is highly rigid and heavy duty.The Roll tools are carved in highly precise CNC machines which gives it best quality and long life .The production of these machines also helps to make and save energy.

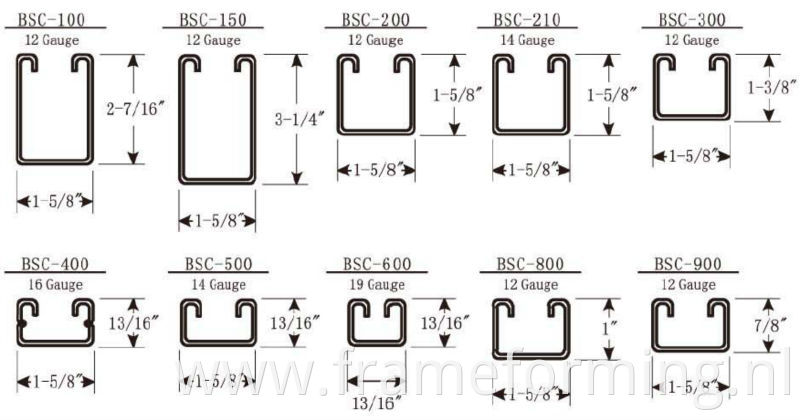

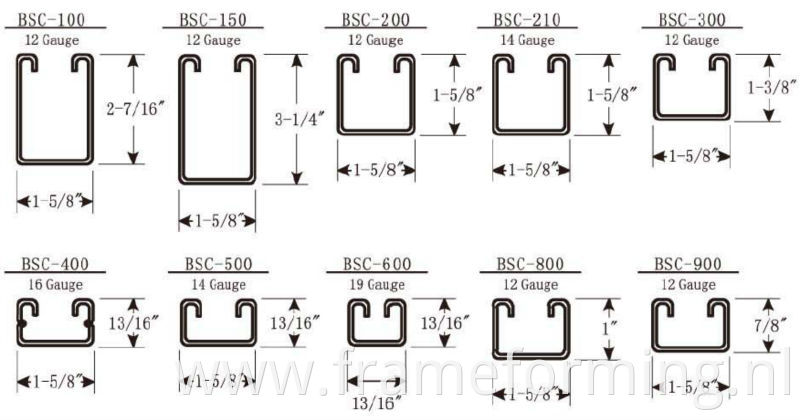

here are some popular drawings as below:

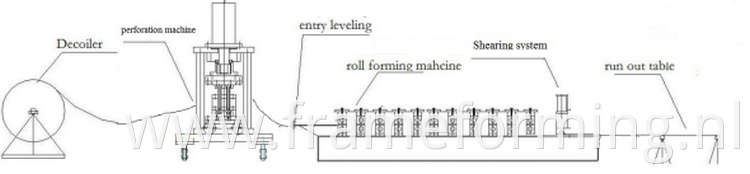

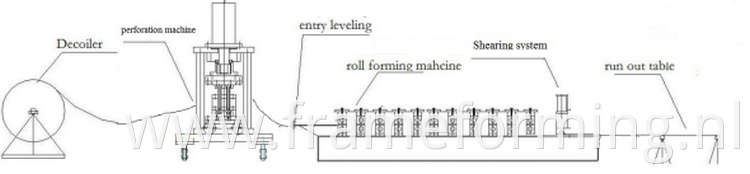

work flow of Steel Strut Channel Roll Forming Machine:

componens of Steel Strut Channel Roll Forming Machine

Entry Beach

Usage: Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

main forming machine

Main power: 5.5kw

Voltage: 380V/50HZ/3Phase

Frame type: Memorial arch frame

Frame thickness: 25mm

Drive mode: By gear

Material of rollers: GCr12MoV

Material of shafts: 45# steel with tempering

Diameter of shafts: φ40mm

Number of rollers: 11 rollers

Material: GI/PPGI

Material thickness: 0.3-0.6 mm

Forming speed: 25 meter/minute

For this Steel Strut Channel Roll Forming Machine, we add the cooling system. Normally, the customer need a large quantity for the production.

So the machine need work long time to match the market need. The rollers will get hot during long time working.

The cooling system ensure the machine work long time with trouble from the temperature.

Hydraulic cutting system:

Function : Automatic cutting controlled by electric control system

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: Gcr12MoV quenched

Power supply : Hydraulic power

Hydraulic Station

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

Station quantity: 2 sets

Hydraulic motor Power: 3kw

Hydraulic oil: 46# hydraulic oil

Volume: 30L

Components: The system includes a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes. and two sets of electromagnetism valves.

Electric Control System

1. Adopted PLC, transducer, touch panel to ensure high speed with stability, precision and lifetime.

2. Voltage: 380V/50HZ/3Phase

3. Language: English and Chinese

4. Automatic length measurement

5. Automatic quantity measurement

6. Length Tolerance: 3m±1.5mm

7. Length inaccuracy can be amended easily.

8. Operating panel: touching screen and button together.

9. Equipped with movable switch , air break, radiator, transformer & electric leakage protector for operation convenience and safety.

packing :

1. One 20ft container for loading one set corrugated roof panel roll forming machine with Manual Decoiler.

2. The whole wiped anti rust oil ,PLC controller covered by foam film.

3. Spare parts and some small parts packed in plastic tooling box.

4. All components of Deck Roll Forming machine fixed by steel wire.

our services

1. Installation and training:

a.If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also train your workers/technician face to face.

b.Without visiting, we will send you user manual and video to teach you to install and operate.

C.If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary things.

2. After Service of stud and track cold roll forming construction machinery

a.One year guarantee for whole machine.

b.24 hours technical support by email or calling

c.If there is any problem found of the machine, we will repair it for free in one year.

Product Categories : C/U/ Channel & T Bar Roll Forming Machine > Drywall Profile Roll Forming Machine