interlocked/ nestable embossed slot vented decking or hangar tabs

Floor Deck Roll Forming Machine

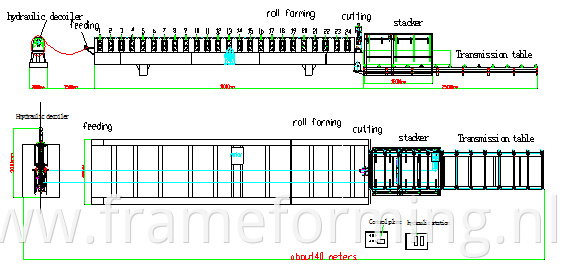

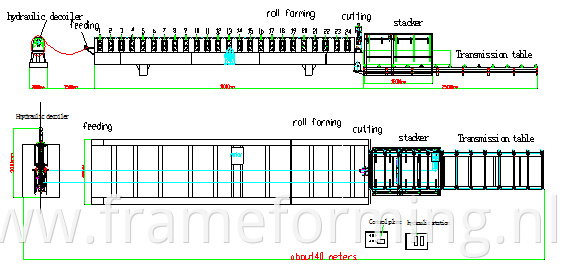

Below is the drawing of the floor deck Roll Forming Machine for your reference:

Raw materials for your reference:

1.The sheet Thickness:0.3-1.2mm

2.Feeding Width:1200mm

3.Finished Width:914mm

The floor deck forming machine work flow

5T decoiler with car -Feeding-Roll forming-Hydraulic cutting- Receive table

5 Ton uncoiler

Usage:Support the raw material and open the raw material and help the raw material into the machine

Supporting Weight: 5T

Inner diameter:450-550mm

The max supporting coil width: 1250mm

Raw material feeding

Usage:It is used to level the steel coil and guide the coil into the forming machine system.

Main forming machine (Pictures are just for your reference):

Usage:In order to protect the products shape and precision ,we take use of the welded frame structure.Chain drive transmission.(From The first roller station to the last roller station, the up and down use the chain drive transmission.)

The cutting system(The machine pictures just be for reference)

Floor deck roll forming machine Hydraulic stations

working principle :Hydraulic stations is controlled by the gear Controlled by the gear oil pump.The hydraulic oil into the oil box, and after start the oil pump, the knives start work.

power:5.5kw

Hydraulic oil:46#

Including:hydraulic box, hydraulic oil pump, two hydraulic tube, and two set of solenoid valve.

The payment and other item:

Price and payment 1.Price: FOB 25,000

2.Payment terms:T/T,30% as in advance,the balance before the machine delivery

3.Delivery time:30 working days after receiving the deposit

guarantee period 1.Warranty: Support the technology all the life. And the machine broken because of quality, we can change the broken part for free within one year.

2. Training: If you come to our factory, we can teach you for free. If you need technician go foreign, the buyer need pay the cost for visa, hotel, ticket, food and others, and buyer need pay the technician USD80/day for salary.There need one technician. Training time will be one week.

Product Categories : Floor Deck Roll Forming Machine