Roof Ridge Cap Roll Forming Machine Ghana

The coil width of Metal Ridge Cap Tile Making Machine is usually from 300-550mm. The thickness of Metal Ridge Cap Tile Making Machine is between 0.25-08mm.It can continuous form the steel sheet according to customer`s requirement, automatically cut to length. This equipment has many advantages, just like light weight, high forming speed,low noise, stable transmission, easy operation, good look and so on.

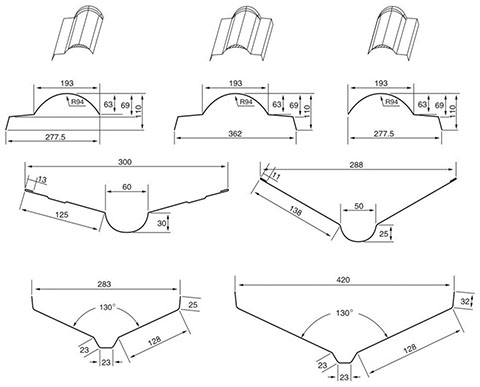

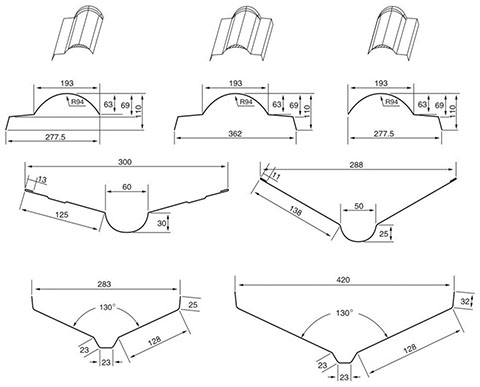

Drawings profile or finishes product pictures

General overview of Metal Ridge Cap Tile Making Machine

Working flow of Metal Ridge Cap Tile Making Machine

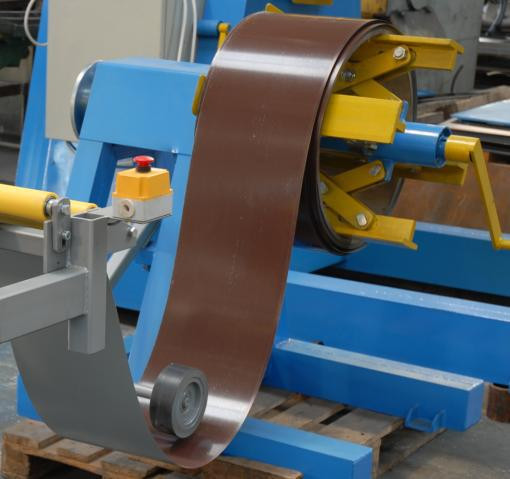

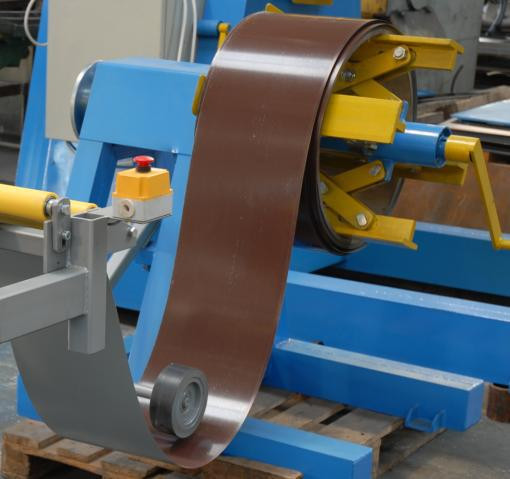

Uncoiler System of Metal Ridge Cap Tile Making Machine

Usage: It is used to support the steel coil and uncoil it in a turnable way.

Passive uncoil pulled by roll forming system

Loading capacity: 5T

Uncoiling width: 1000mm

Inner diameter: 450-550mm

Entry Beach of Metal Ridge Cap Tile Making Machine

Usage: Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity.It is set in the beginning of the main machine with left-right guiding. It can help the operator to make the sheet in the right direction, left side and right side can be adjusted separately by manual screw structure.

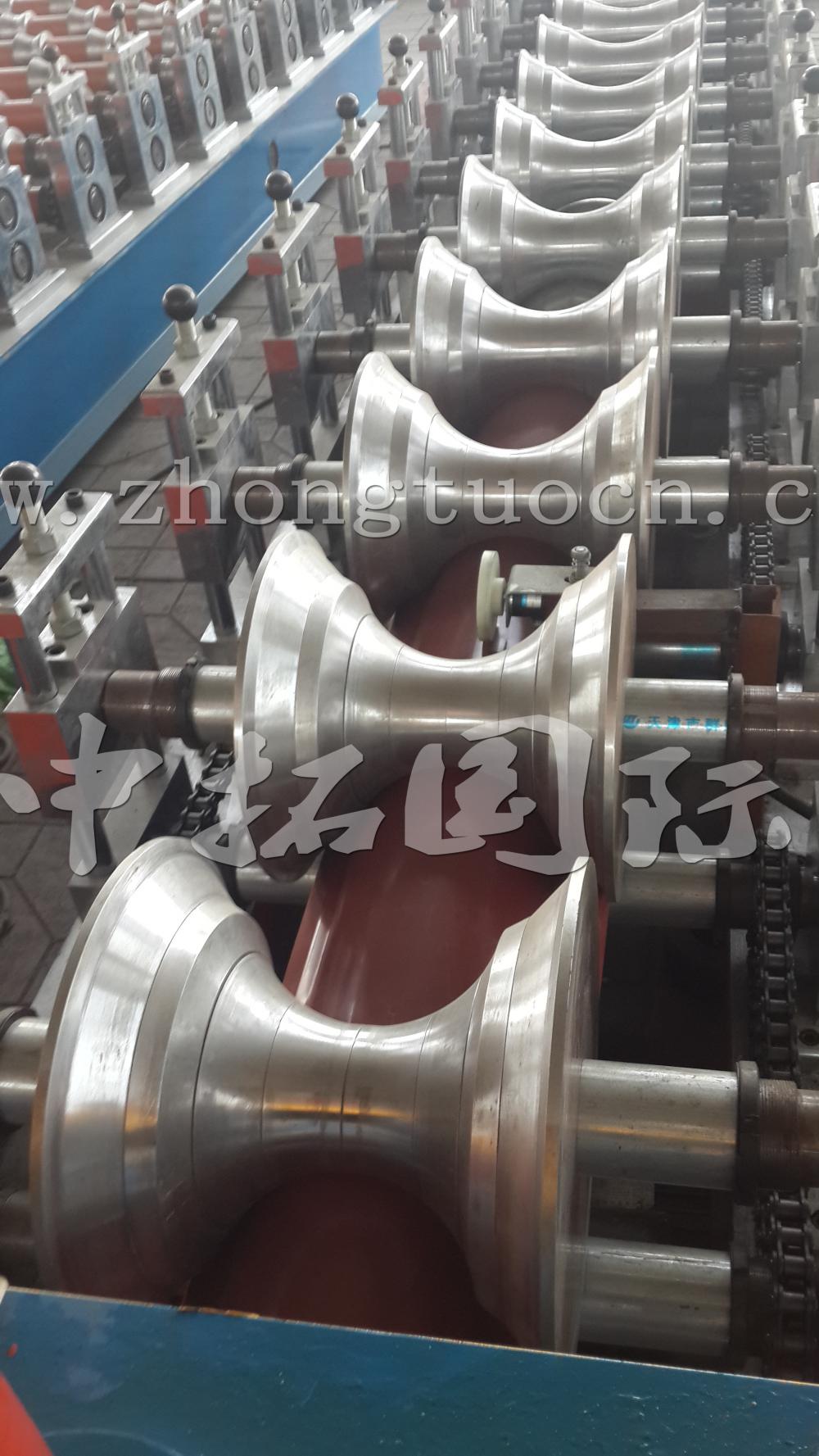

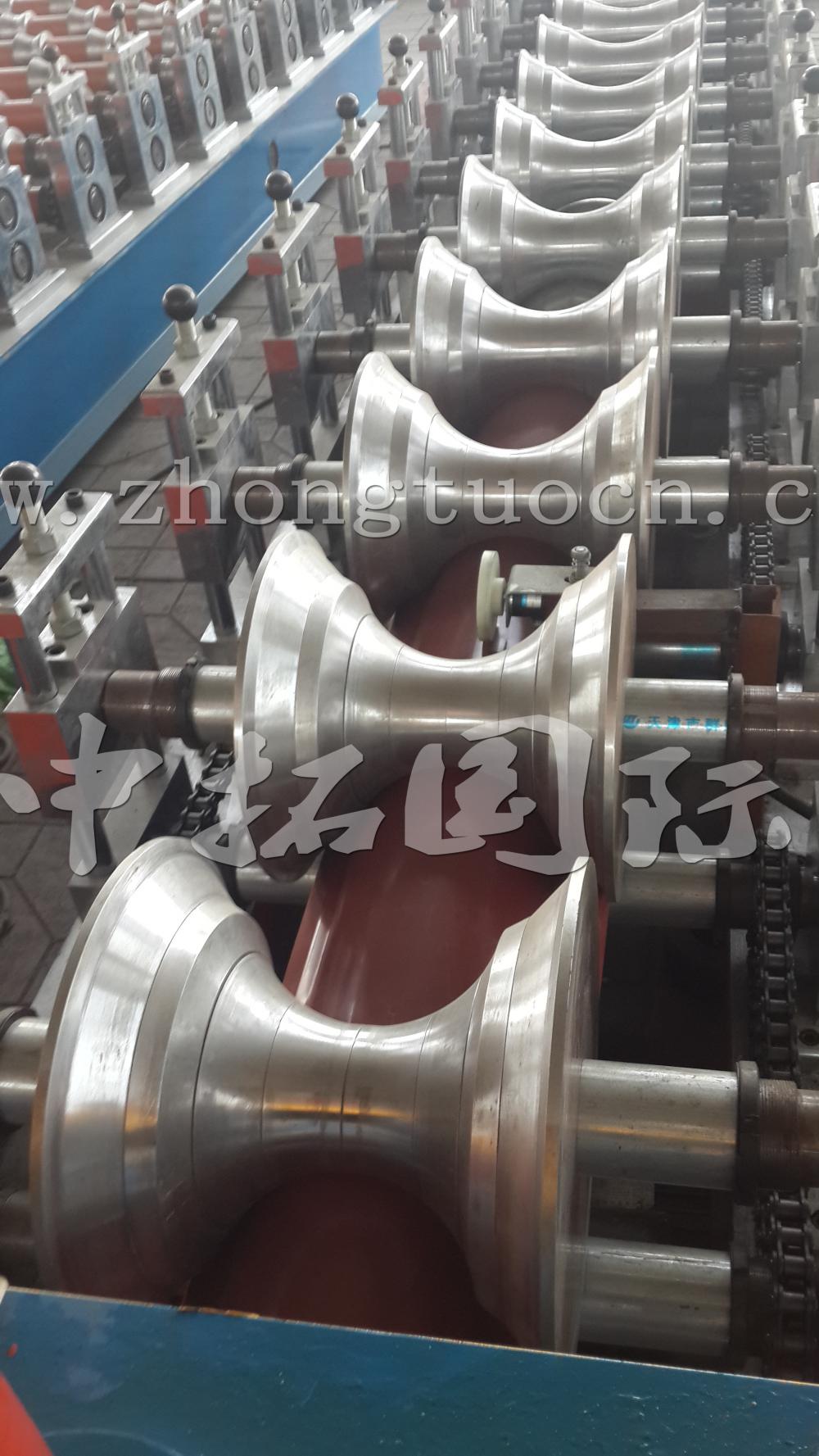

Main Roll Forming System of Metal Ridge Cap Tile Making Machine

Length of the main part: about 6500*1300*1400

Weight of main part: 3.5 tons

Voltage: 380V/50HZ 3Phase or as customer's request

Roller fixer: middle plate

Frame: 350 H steel welded

Drive mode: chain

Material of rollers:45# steel, surface hard chromium plating.

Material of shafts: 45# steel

Diameter of shafts: φ60mm

Number of rollers: 11 rollers

Main power: 3.2kw

Step-formed mechanism

Feature: it is used to make the step , the glazed tile's final formed

Material of mold: Cr12 quenched

Shearing Mechanism of Metal Ridge Cap Tile Making Machine

Feature: Ensure stability, precision and cutting speed

Function: Automatic cutting controlled by PLC

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: Cr12 quenched

Power supply: hydraulic power

Components: It contains one set of blade, one hydraulic tank and one cutter machine.

Hydraulic Station of Metal Ridge Cap Tile Making Machine

It is controlled by gear pump. After filling the hydraulic oil into the hydraulic oil tank, the pump drives the cutter machine to begin the cutting job.

Power: 5.5kw

Hydraulic oil: 46#

Components: The system includes a set of hydraulic tank, a set of hydraulic oil pump, and four hydraulic pipes. and two sets of electromagnetism valves.

Electric Control System of Metal Ridge Cap Tile Making Machine

Feature:

1.Adopted PLC , frequency converter , Delta touch screen from Taiwan to ensure high speed with stability, precision and lifetime.

2.Other electric element are Panasonic

Product Categories : Roofing Sheet Roll Forming Machine > Glazed Tile and Ridge Cap Roll Forming