Steel Crash Barrier Forming Machine

Steel Crash Barrier Forming Machine, also known as Steel W Beam Roll Forming Machine, is commonly used for producing crash barrier and W shaped guardrail. In order to improve road safety, the crash barrier is designed to prevent vehicles from leaving the roadway.

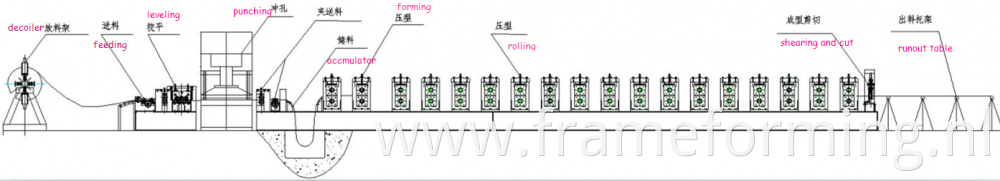

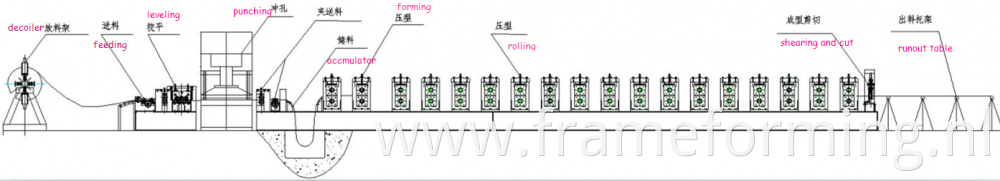

Steel Crash Barrier Forming Machine is mainly composed of uncoiler, feed leading table, main forming machine, punching system, cutting device, hydraulic station and computer control system.

Working process:

Detailed information of Steel Crash Barrier Forming Machine:

Hydraulic decoiler

Usage: It is used to support the steel coil and uncoil it in a turntable way.Passive uncoil pulled by roll forming System.

1.ID:500-550mm

2. Coil width:500mm

3. Loading ability:5000kg

4. Hydraulic power:3kw

5.Motor:3kw

Feeding and leveling part

1. Roller material after quenching

2. 9 rows station for leveling: 4 5

3. The diameter of raw material 95mm ,45 steel after quenching

4. Feed a side wheel GCR15 raw materials, after quenching

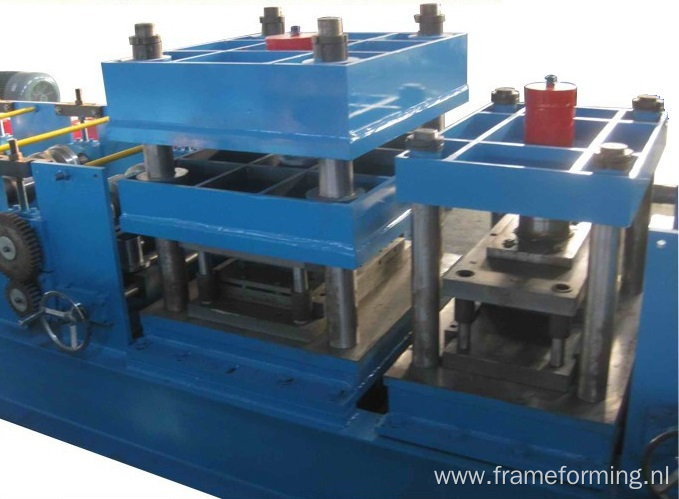

Punching and shearing part

1.Hydraulic punching, raw material after quenching Cr12,Which can be welded, which need to bolt

2.Shearing blade material:Cr12 after quenching.

3. Shear error: +/- 2mm

Roll forming machine

Advantage: to make sure long time using, working steady and high speed.

1. Main-length: about 20.5*1.2*1.5m

2. Machine weight: 15.5 Ton

3. Voltage: customer choice

4. Fix wheel types: medium plate

5. Frame: 400# steel

6. Transmission: Chain

7. Shaft material: 45 steel after adjusting treatment, the diameter of 100mm, precision machining

8.Roller material: GCR15, after quenching, and after chrome wheels.High strength bolt

9. Rolling station:20 stations

10.Main power:45kw

Shearing system

Advantage: to make sure machine working speeds fast, accurate and steady.

Usage: controlled by PLC, driven by hydraulic power to shear accurate and accurately.

Shearing blade material:Cr12 after quenching.

Shear system: automatic hydraulic shear system, advanced, no waste edge, high security.

Shear error: + 2mm

We use PLC and encoder. This type is higher than the photoelectric measurement.

Component: it includes a set of tools, a hydraulic cabinet and a knife machine.

Hydraulic system

1.Power: 18.5kw

2.Hydraulic oil type: 46#

3.Component: the system includes a set of one or two sets of hydraulic oil tank, hydraulic pump, hydraulic pipe line four, two sets of solenoid valve.

Electrical system

1.Panasonic 1.5.7 inch touch screen is Japan's Panasonic brand, to ensure high speed and stability, accuracy and service life.

2.Panasonic PLC, Panasonic inverter

3. automatic fixed length

4. automatic counting

Automatic stop shear length control. Equipped with 5 movable switch, fuse, radiator, transformer and convenient operation and safety of leakage protector.

Product Categories : Guard Rail Roll Forming Machine