Zhongtuo Roll Forming Machine

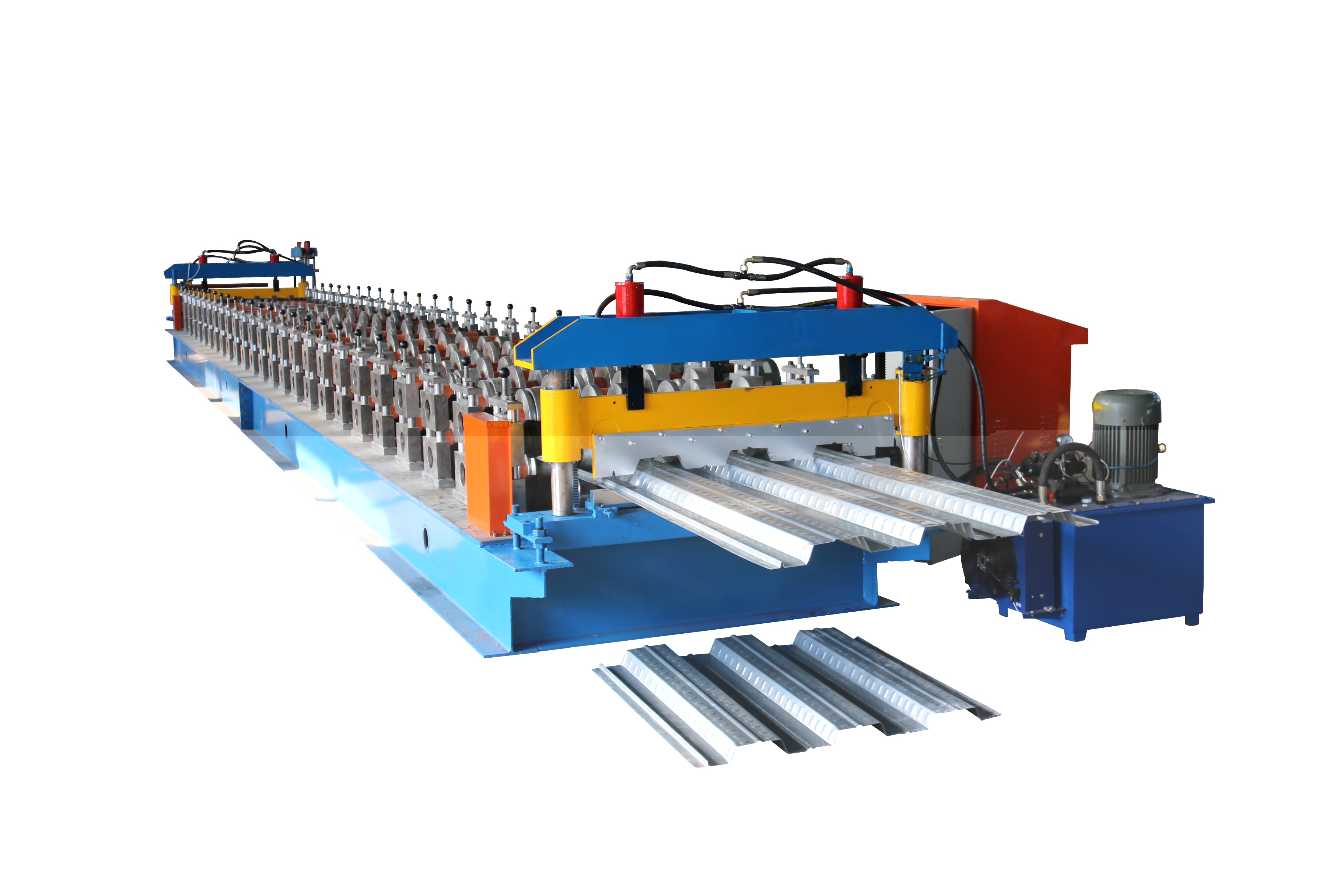

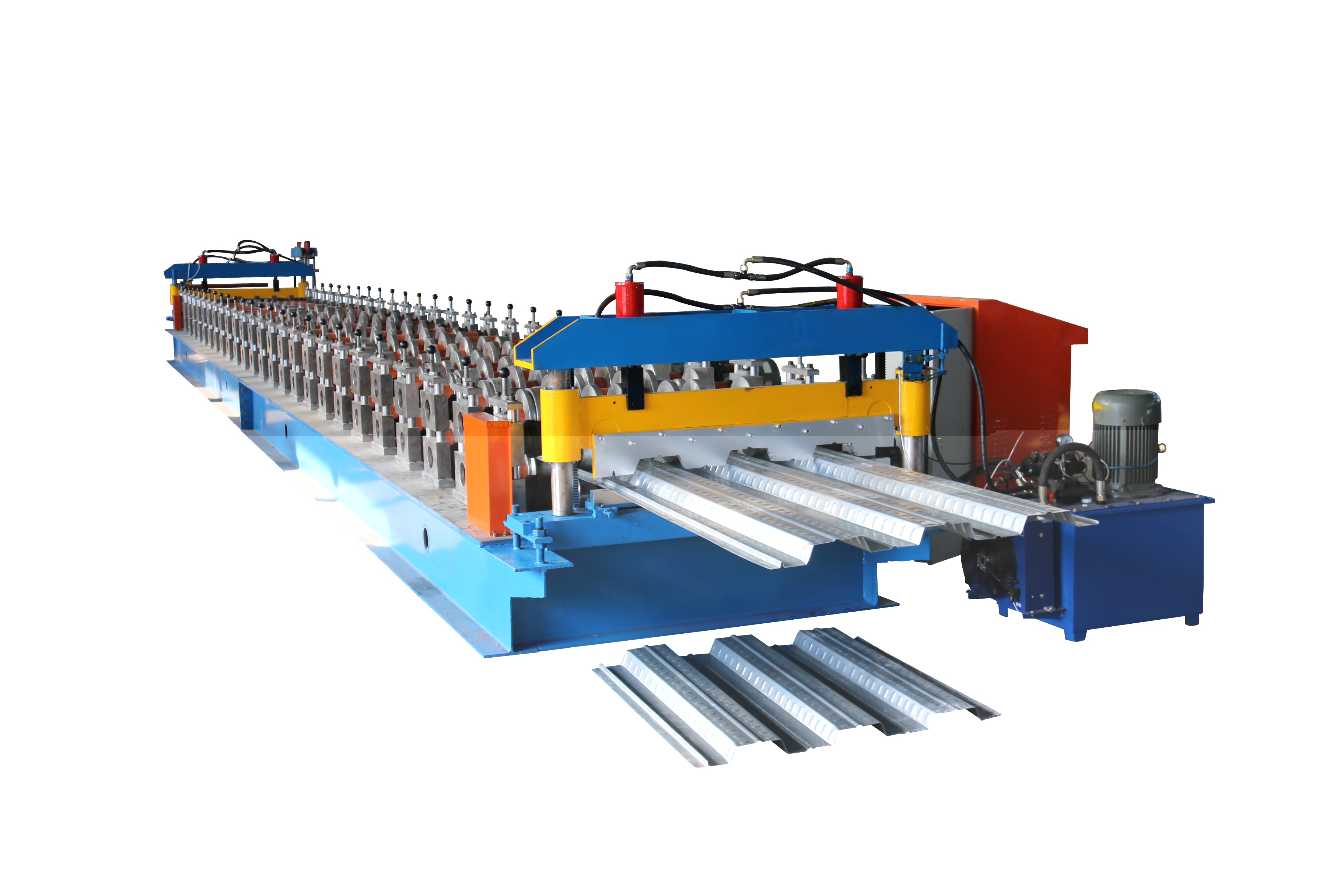

Steel structure floor roll forming machines

Steel structure floor roll forming machines

Decking floor production roll forming line

Decking floor production roll forming line speeds up to 25m/min, it is possible to produce various profiles through add quick-change unit. The whole line can be controlled by remote controller, integral guard was covered on the machine, which complying with European Unions safety standards and has been passed CE.

MATERIAL:

1. Suitable Coil Thickness 0.3 mm-1.5mm

2. Coil Width: 800mm~1250 mm

2. Suitable Raw Materials:Galvanized coil ,Pre-painted Coil

3. Yield bearing stress 235 MPa

MACHINE COMPONENTS

1. Hydraulic Un-coiler with coil car

2. Raft style Roll-Forming M/C

3. Hydraulic Cutting

4. PLC Control System

5. Automatic Product Rack

6. Line speed:10~20m/min.

| NO. | Model | Coil width | Thickness | Effective width | Profile drawing | | 1 | ZT28-200-1000 | 1250 | 0.3-0.7 | 1000 |  | | 2 | ZT36-196-980 | 1250 | 0.4-1.0 | 980 |  | | 3 | ZT30-350-1050 | 1200 | 0.3-0.7 | 1000 |  | | 4 | ZT31-200-1000 | 1220 | 0.3-0.8 | 1050 |  | | 5 | ZT25-205-1025 | 1200 | 0.3-0.7 | 1025 |  | | 6 | ZT28-200-800 | 1000 | 0.3-0.7 | 800 |  | | 7 | ZT28-205-820 | 1000 | 0.4-0.6 | 820 |  | | 8 | ZT25-210-840 | 1000 | 0.4-0.6 | 840 |  | |

|  |  |

|  |  |

Product model picture

Steel roof tile roll forming machine

Wide cold glazed tile roll former

MATERIAL:

(1) Coil Width: 1000 mm~1250mm

(2) Suitable Coil Thickness: 0.3mm - 0.6mm

(3) Suitable Raw Materials: Pre-painted Coil;

(4) Yield bearing stress: 235MPa

MACHINE COMPONENTS:

(1) Un-coiler 1 set

(2) Roll-Forming M/C 1 set

(3) Hydraulic cutting 1 set

(4) Product Rack 1 set

(5) Hydraulic System 1 set

(6) Electrical Control System 1 set

(7) Safety Barrier System 1 set

Roll-Forming M/C:

The roll forming craft is made by the special Germany cold roll forming program COPRA; the craft is also made the FEA analysis and check. The roller surface has been fine finished; make sure the profile is smooth.

About -13 steps to form; Material of Roller: 45# steel, Chroming and polishing on the surface.

The machine base adopts welded steel plate structure; Chain and gear move the line, motor drives.

| NO. | Model | Coil width | Thickness | Effective width | Profile drawing |

| 1 | ZT29-185-925 | 1000 | 0.3-0.7 | 925 |  |

| 2 | ZT40-257-1028 | 1250 | 0.4-1.0 | 1028 |  |

| 3 | ZT52-169-845 | 1000 | 0.3-0.7 | 845 |  |

| 4 | ZT45-253-760 | 1000 | 0.3-0.8 | 760 |  |

| 5 | ZT39-190-950 | 1000 | 0.3-0.7 | 950 |  |

| 6 | ZT25-210-1122 | 1200 | 03.-0.7 | 1122 |  |

| 7 | ZT24-200-800 | 1000 | 0.4-0.6 | 800 |  |

| 8 | ZT40-200-1000 | 1200 | 0.4-0.6 | 1000 |  |

Product model picture