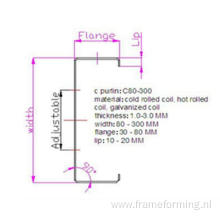

C U purlin forming machine

The biggest difference between the c u profile stud and purlin is that the thickness. The C U purlin often used as the support of the building.The thickness range of the purlin is 2.0-4.0mm while the c u light steel stud is :0.3-0.8mm so the c u purline machine is much stronger , with big electric power and thick blade which can cut the purlin .

Processing flow diagram of machine

Manual Decoiler→Feeding material into machine →Roll Forming Machine →Measure length →Hydraulic cutting →Finished Products

Decoiler

Usage: It is used to support the steel coil and uncoil it in a turntable way. Passive uncoil pulled by roll forming system

Loading capacity: 3T

Uncoiling width: 500mm

Inner diameter: 450-550mm

Main roll forming machine:

Feeding and flatting will make sure the steel is neat clean and straight.

Voltage:380V/50HZ 3Phase(as customer`s request)

Roller fixer : Guide column

Frame : middle plate welded Memorial arch frame type

Speed: 5-50m/min

Drive mode: gear

Material of rollers: GCr12MoV

Material of shafts: 45# steel with tempering

Diameter of shafts: φ40mm

Number of rollers : 10rollers

Main power: 4kw

Shearing Machine:

Material of blades: Gcr12 quenched

Power supply : hydraulic power

Frame : Pillar style with rack & pinion system

Stroke switch : non-contact photoelectric switch

Electic Control System:

1. Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.

2.The machine is with servo tracking cutting, the cutting knife can move automaticly. so that, the tracking cutting can keep same speed with the main forming machine, and cut the finished products cntinually.

Packaging Detail of glazed roofing sheet cold roll forming machine:

1. One 40ft container for loading one set machine with manual decoiler;

2. The whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

Product Categories : C/Z/U Purline Roll Forming Machine > Purline Roll Forming Machine