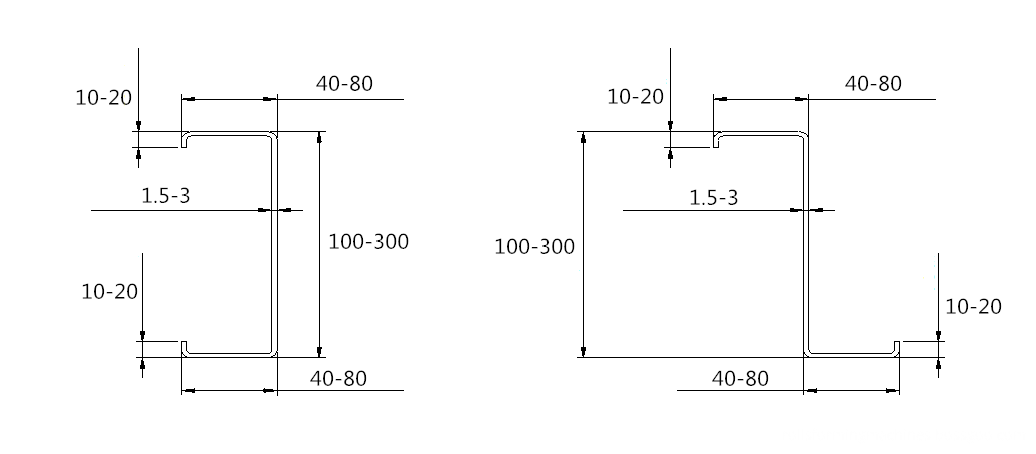

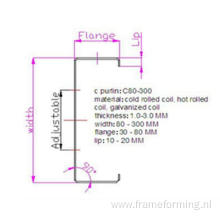

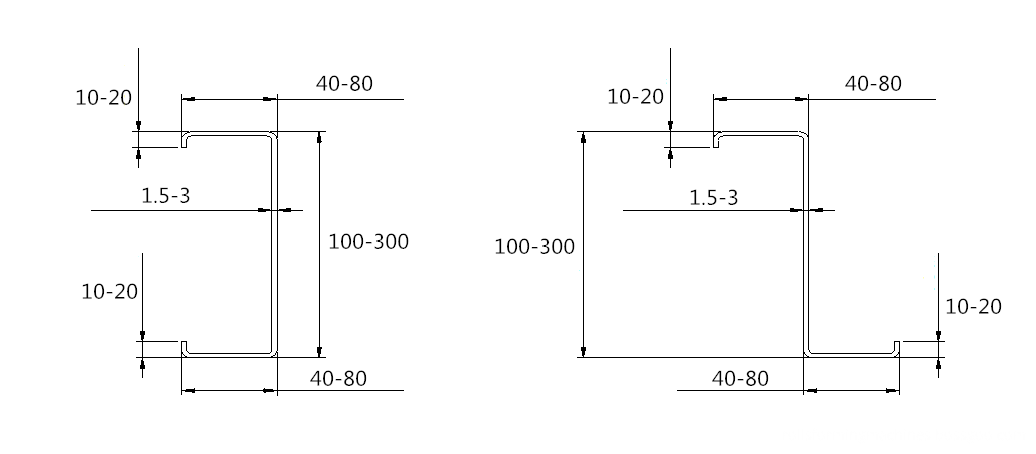

This cz interchangeable roll forming machine can produce C Z purlin .You can set on the PLC for different sizes. When you want to get Z purlin, rotate the rollers manually.

Pls refer to the videos

Video:https://www.youtube.com/watch?v=-bdb6lmPc8A

https://www.youtube.com/watch?v=PdtOC3lDuZo

https://www.youtube.com/watch?v=F2_g7ZVsWhY

technical parameters of cz interchangeable roll forming machine

| It is used to support the steel coil and uncoil it in a turntable way. Passive uncoil pulled by roll forming system. Capacity: 5 Tons Loading width: Max 550 mm Valid expanding range for coil inner diameter: 450-610 mm |

| Adjustable center of the forming rollers and of sufficient length to prevent lateral movement of the strip on its entry to leveling system. Feeding type: Adjustable Feeding width range:150-550 mm Entrance and guide roller: Diameter is¢80 mm Roller material: SAE 1045, HRC 48-52 surface with chrome |

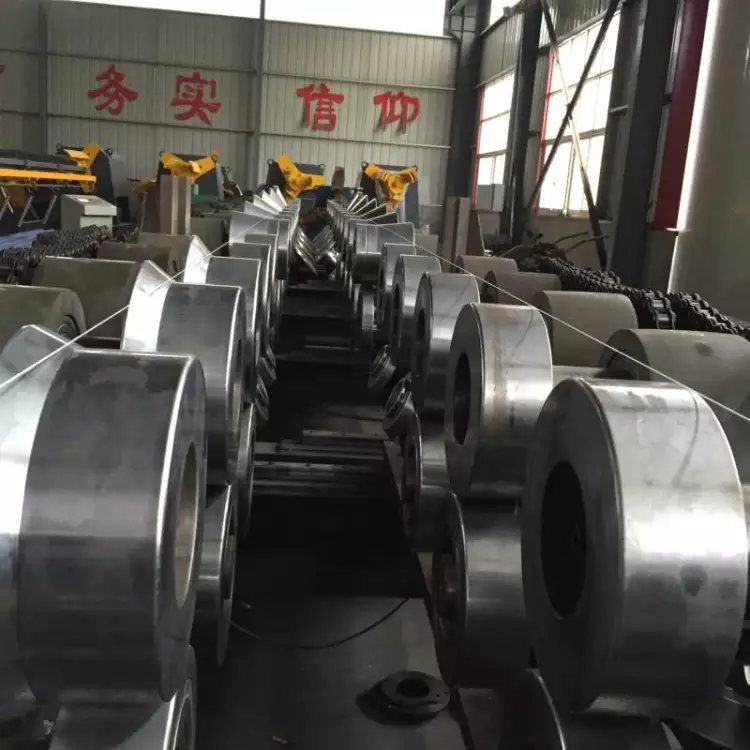

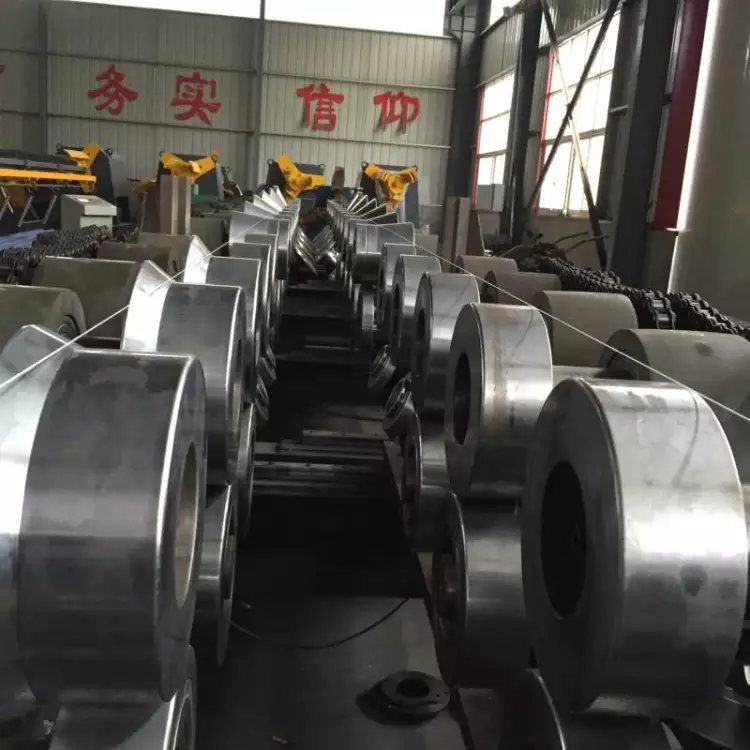

| Machine base frame adopt H beam welding steel. In the main roll forming machine have 2 buttons for urgency stop if happen any malfunction. Machine adopt iron cast as station to make machine in strong. To avoid accidents, all of drive part adopt protect cover. Drive type: Chain Roller station: 18 groups Working speed: 8-12 m/minute Main motor power: 18.5 kw Width adjust motor power: 4.5 kw (1.5 kw*3 sets) Voltage / Frequency / Phase: 380 V 50 Hz 3 Phase Roller material: Gcr 15 steel and quench treatment hardness HRC 55-58, chrome coated 0.05 mm The width of the profile can be automatic adjusted by the control computer and the last 10 roller stations can be manual overturned to make C or Z purlin. |

| The hydraulic cutting machine with good compression performance, good flatness, automatic fixed-length cutting, high degree of automation. Cutting blade: Cr 12 mov Cutting tolerance: 12 m +/- 1.5 mm Cutting type: Hydraulic cutting after forming Auto cutting when reach the length set on the computer. The width and height of cutting blade can be manual adjusted . |

| Table for reception of the cut profiles, there are rollers on the table to unload the cut profile freely. Frame: Welding by steel angle Diameter of support rollers: 55 mm Roller material: ASTM 1045 with chrome Table size: About 2.0 *0.6 * 0.9 m (L*W*H) Table color: Blue or base on customer request |

| It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank , the pump drive the cutter machine to begin the punching and cutting job. Hydraulic motor : 7.5 kw Hydraulic oil: 46# 60 L Components: The system includes a set of hydraulic tank , a set of hydraulic oil pump, three hydraulic pipes and three sets of electromagnetism valves. |

| The PLC (Programmable Logic Controller) powered by the software that controls the automation of the processes of the forming, cutting and punching. It adopt the latest technology that allow the operator enter all data through a touch screen quickly and reliably to meet a predetermined production. Voltage/ Frequency / Phase: 380 V 50 Hz 3 Phase Automatic length measurement Automatic quantity measurement Length Tolerance: 6 m ±1.5 mm Length inaccuracy can be amended easily. Language: English and Chinese Control panel: Button-type and touch screen |

our service

1. training

a.we will send you user manual and video to teach you to install and operate.

b.If buyer needs our technicians to go to your local factory, please arrange board and lodging . And the buyer need pay the technician USD80/day for salary.

c.There need one technician for one week.

2.After sale Service

a.One year guarantee for whole machine.

b.24 hours technical support by email or calling.

c.If there is any problem found in ourmachine, we will repair it for free in one year.

Packing

1.One 20ft or 40ft container for loading one set machine with Manual Decoiler.

2.The whole wiped anti rust oil ,PLC controller covered by foam film.

3.Spare parts and some small parts packed in plastic tooling box.

4.All components of Deck Roll Forming machine fixed by steel wire.

Product Categories : C/Z/U Purline Roll Forming Machine > Purline Roll Forming Machine