- Home

-

Products

- Roofing Sheet Roll Forming Machine >

- Roller Shutter Door Forming Machine

- Double Layer Roll Forming Machine

- Sandwich Panel Roll Forming Machine

- Welded Tube Mill >

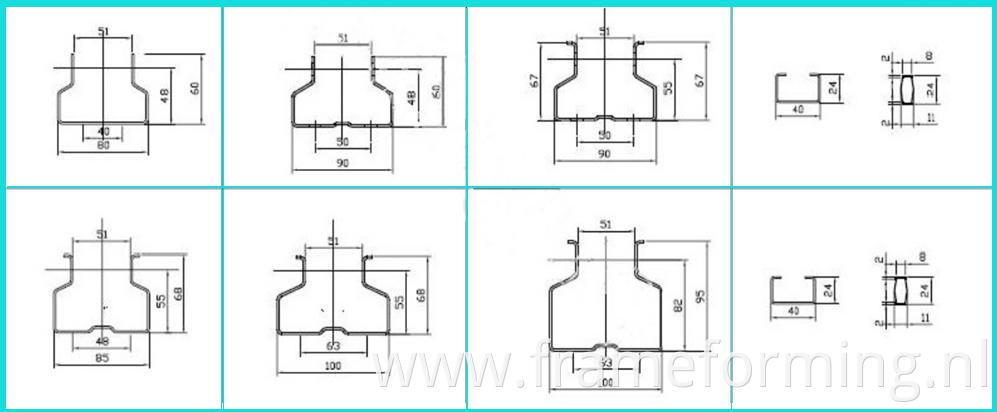

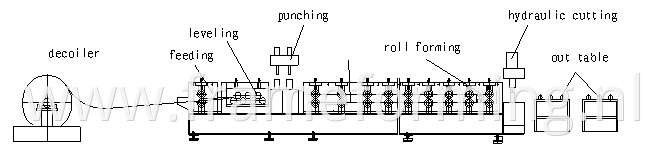

- C/U/ Channel & T Bar Roll Forming Machine >

- Guard Rail Roll Forming Machine

- Slitting Line/Cut To Length Line

- Floor Deck Roll Forming Machine

- Stone Coated Roof Production Line

- Roofing/ Wall Panel Sheet

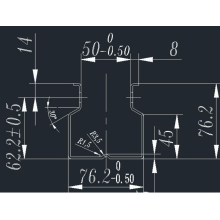

- Door Frame Roll Forming Machine

- Racking Roll Forming Machine

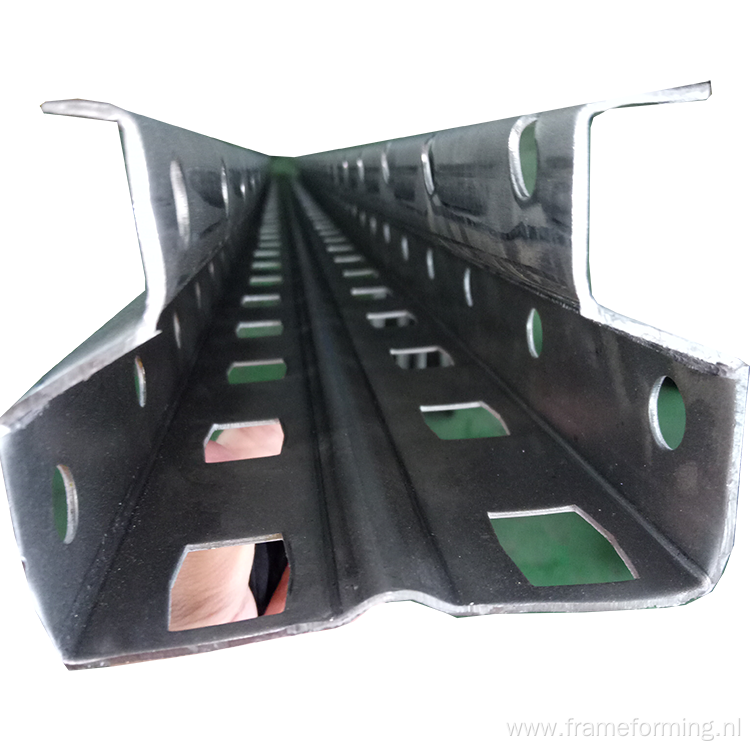

- Cable Tray Roll Forming Machine

- Accessories Equipment

- Coil Sheet

- C/Z/U Purline Roll Forming Machine >

- Special Equipment For Industry

- Steel Pipe Roll Forming Machine

- Gutter & Downspount

- Metal Processing Line

- About Us

- News

- Contact

- Download