door frame machine Door Frame Roll Forming Machine

The door frame is one channel that can fix the door to the wall and to make the door is strong standing inside the wall of the house, the door frame machine we make is steel door frame. and we produce this kind door frame machines. The door frame machine is similar to other machines, including below parts: de-coiler, the leveling, the punching holes system, the Roll Forming Machine, and the cutting system and the receiving table.

The door frame machine need 45 cutting system to for the 45 door frame forming system. and the door frame machine need the punching system because there are some holes on the door frame. so we designed the punching system before the main roll forming machine body.

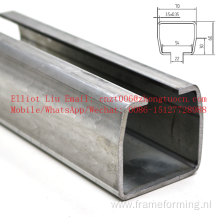

below are some machine pictures of the steel door frame roll forming machines:

The thickness is usually 1.0 mm- 2.0 mm

Below is some details of the door frame machines:

Processing flow diagram of machine:

3 Ton Hydraulic decoiler→leveler and servo feeder→hydraulic punching system→roll forming machine→strengthening→hydraulic cutting →product receiving table

(Machine pictures are for your reference)

First part: 3 Ton hydraulic Decoiler

This part is composed by the following elements: 3 Ton Hydraulic decoiler

3 Ton Hydraulic decoiler:

Loading ability: 3T Max coil width:400mm

Inner diameter:450-508mm outer diameter: Max 1500mm

Forth part: roll forming machine

1.Feature Ensure the stability, accuracy and long life

2.Main forming machine Size 8500mm*1200mm*1500m(L*W*H)

3.Main forming machine weight 7.5Ton

4.Voltage 380V 50Hz 3 Phrase (380 V is China normal voltage, but the voltage can be customize by customer.)

5.Method for fixing roller Memorial arch frame

6.Material of shafts 45# steel Thermal refining

7.Transmission method Gear drive

8.The main shaft material No. 45 steel quenching and tempering treatment

9.Outer shaft diameter 60mm

10.Wheel material Quenching process of GCr15 bearing steel HRC58-60

11.Roller16 stations

12.The main motor power: 7.5kw

Sixth part hydraulic station

1.Hydraulic oil 46#

2.Hydraulic power 4kw

3.Components The system includes a set of hydraulic tank ,

a set of hydraulic oil pump, two hydraulic pipes.

and two sets of electromagnetism valves

Seventh part PLC Control Device

1.Control By PLC

2.PLC language As required

3.Touch screen Delta

4.Function Automatic length and quantity measurement

5.Include Equipped with movable switch , air break,

radiator, transformer & electric leakage protector for

6.operation convenience and safety.

7.Feature Adopted PLC , transducer, touch panel from

Mitsubishi Japan to ensure high speed with stability,

precision and lifetime.

| If you need this door frame machine or you want to know more about this door frame machine, please feel free contact me as below detailes:

Price: USD /FOBTIANJIN XINGANG CHINA Payment: 30% T/T in advance and balance 70% after inspection confirmation before shipment. ( We can accept other payment items such as L/C,OA ) Delivery time : 45 working days Container need: one 40` Container |

| 1. One year guarantee period, and we will provide the technical support for the machine whole life. 2. The machine is easy to install, we will offer you operating manual and send you operating video If you need engineer install for you, we can send engineer to your workshop. The buyer should charge of visa, return ticket, food and accommodation overseas and USD80/person/day for salary. |

| Before-sales We will answer the customer ASAP. (within 24hours) We can design the machine according to customer`s detail requests. After-service: In correct operation & maintaining, the machine is guaranteed for one year If necessary, we will dispatch technicians to install and commissioning, and also our technicians will teach and training the customer`s workers to use the machine better. We will provide long-term technical assistance. |

Product Categories : Roller Shutter Door Forming Machine