Quickly informations:

1.Main forming unit driving motor power:5.5kw

2.Material of rollers:45#steel,quenched HRC58-62,coated with rigid chrome.

3.Material of roller shafts:45#steel

4.Step of rollers:14steps

5.Forming speed:10-15m/min

6.Thickness to be rolled:0.5-1.5mm

Components of Line

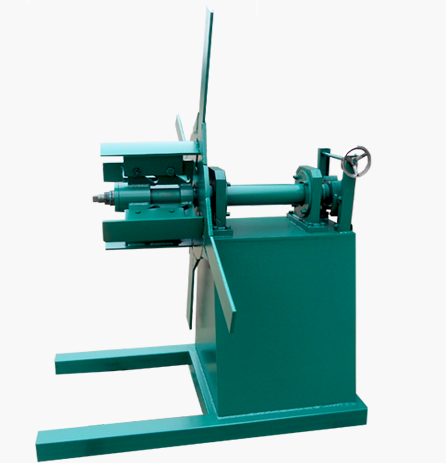

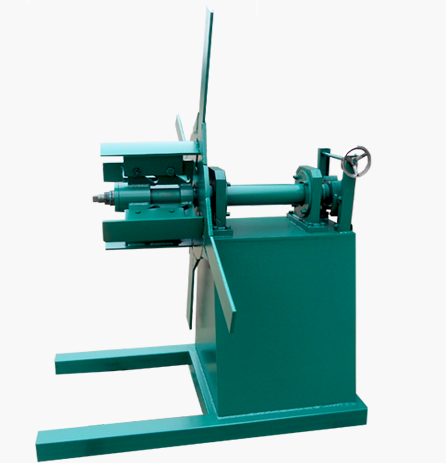

1. Decoiler

Usage: It is used to support the steel coil and uncoil it in a turntable way.

Passive uncoil pulled by roll forming system

a. Coil inner diameter: 450-550mm

b. Coil max width: 300mm

c. Max carrying capacity: 3000kg

(you can choose this part with Electric or hydraulic)

2. Entry leveling and punching dots

This part will level coil to make sure it is neat clean and straight.

3. Roll forming machine

a. Number of forming steps: 14 stations

b. Shaft material: 45# steel with quenched treatment, precision machined,

The diameter: ¢56mm

c. Roller material: bearing steel with quenched treatment

d. Transport: by gear

e. Forming speed: 10-15m/min

f. Motor:5.5kw

g.Voltage:380v, 50Hz,3 phase

h. Structure: independent stand

4. Shearing system

Servo flying and tracking cutting saw, the cutting saw will adjust the cutting speed and location according to the main machine speed. By this method, the machine working speed will be same as the main machine accordingly. The cutting plate we take the best material for cutting it in high speed and beautiful cutting scare.

The material of blade: Cr12Mov, Hardening HRC 58-62℃

Length Tolerance:3m±1.5mm

5. Hydraulic station

Hydraulic motor Power: 3kw

Hydraulic oil: 46#

Hydraulic pressure : 12Mpa

Components: The system includes a set of hydraulic tank, a set of hydraulic oil pump, and two hydraulic pipes. And two sets of electromagnetism valves.

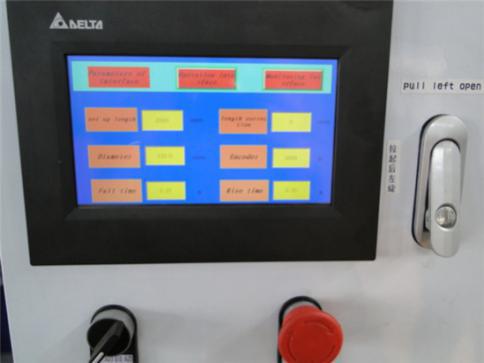

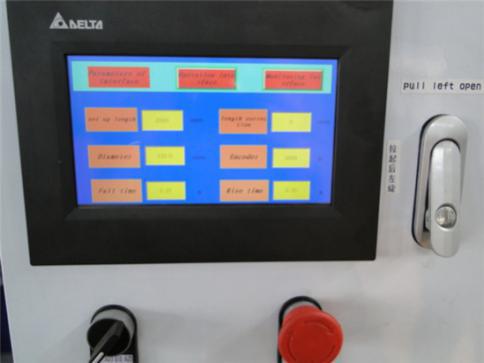

6. PLC station

PLC control system, we will take Panasonic or you can specify the one you like. Different with normal machine, PLC programmed will add servo cutting saw control parameters.

7. Run out table

It adopts welded steel and supported roller to transmit the products.

Product Categories : Roller Shutter Door Forming Machine