Automatic Rolling Shutter Door Making Machine

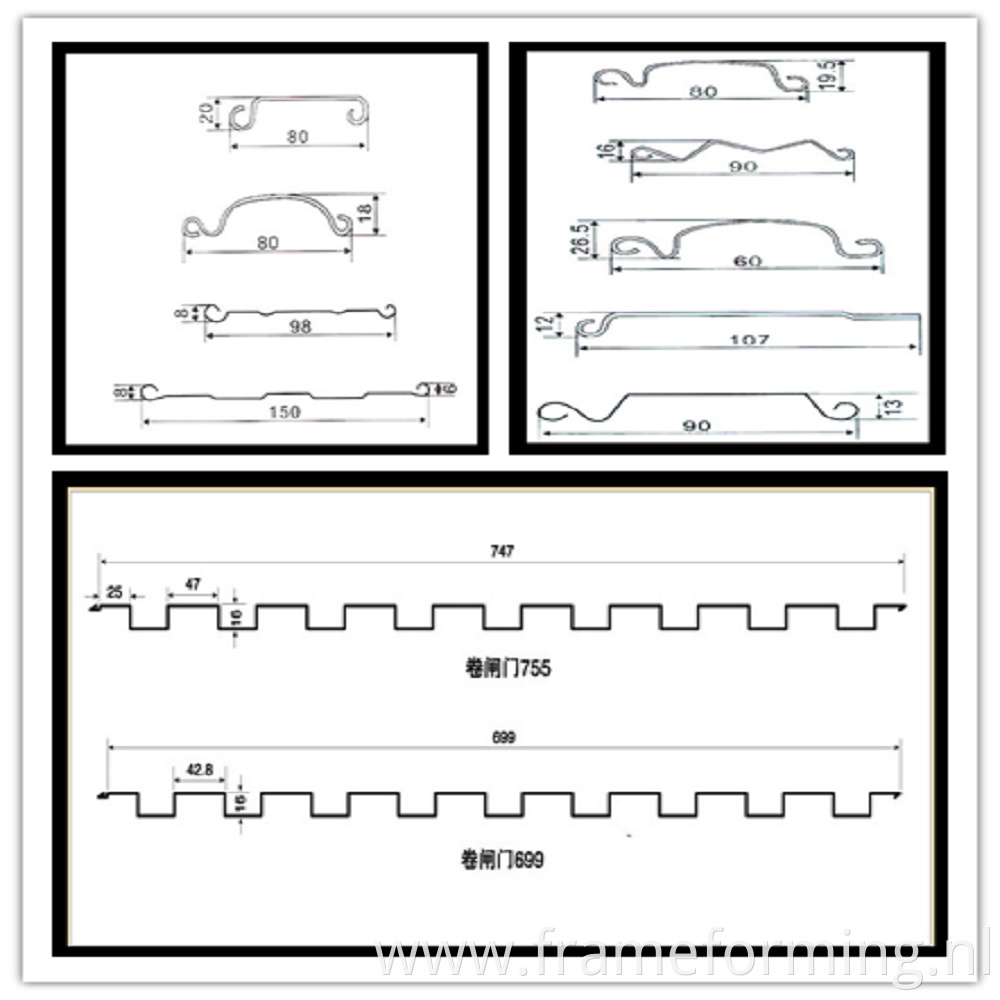

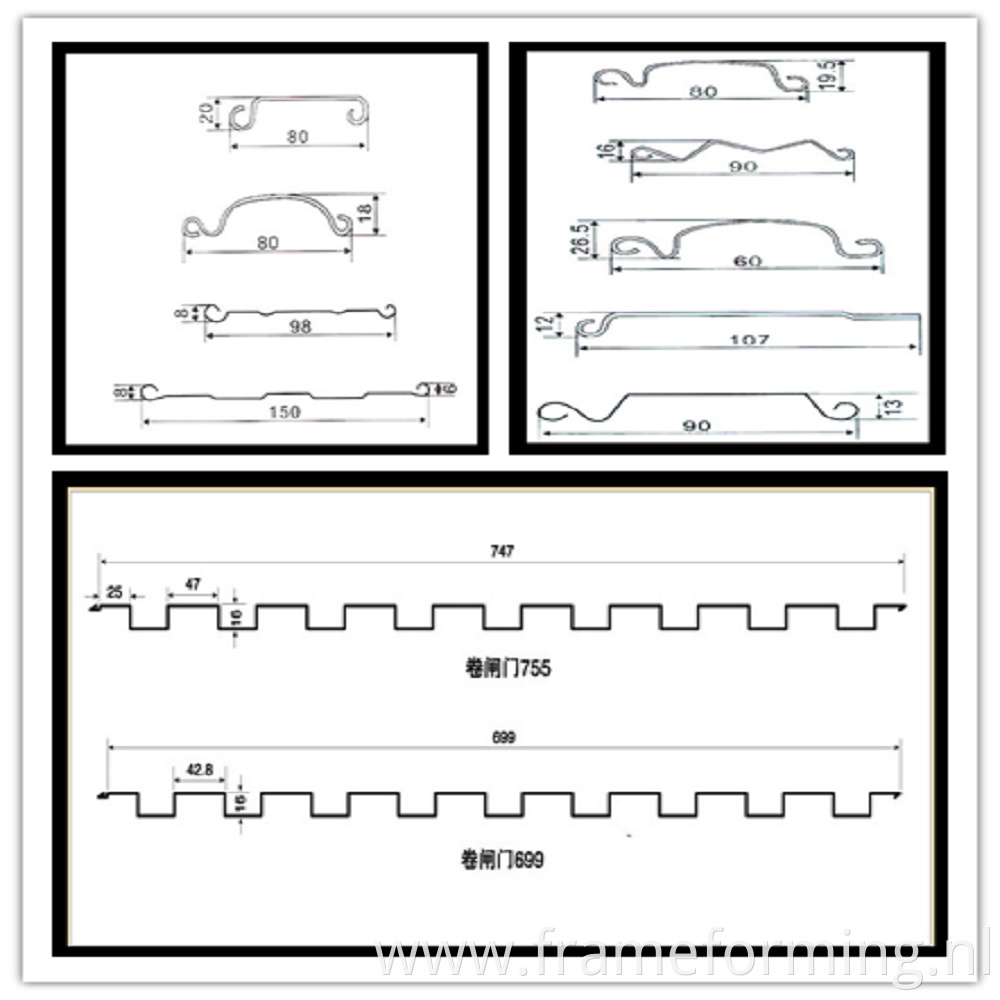

Metal shutter door is widely used in the shop, hotel , bank etc building, because it is easy to open and close , Also very easy to install, For fit this market, we manufactured the High speed Roller Shutter Door Forming Machine. Metal shutter door has many types, here I will take random profile drawing and type for your reference.

Working flow of Shutter Door Roll Forming Machine:

Decoilerà leveling systemà Roll Forming Machineà shearing systemà runout table

Main parameter and basic introduction of shutter door machine:

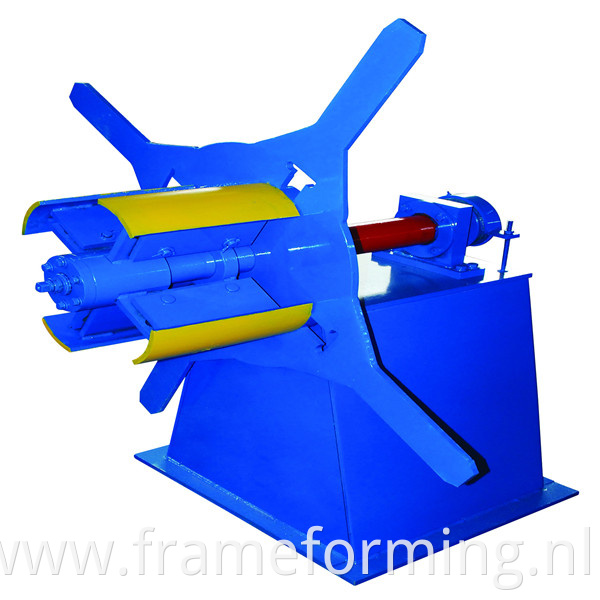

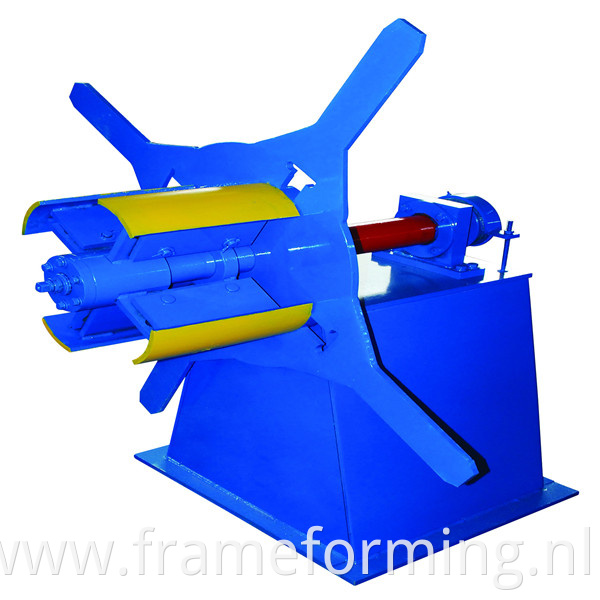

Decoiler:

Usage: It is used to support the steel coil and uncoil it in a turntable way.

Passive uncoil pulled by roll forming system

a.Coil inner diameter: 450-550mm

b.Coil max width: 300mm

c. Max carrying capacity: 3000kg

Leveling system:

Entry leveling and punching dots if you need.

This part will level coil to make sure it is neat clean and straight.

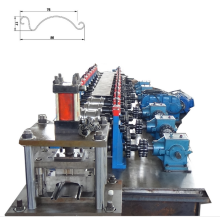

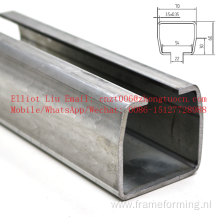

Main roll forming machine system:

a. Number of forming steps: 12 stations

B. Shaft material: 45# steel with quenched treatment, precision machined,

The diameter: ¢40mm

c. Roller material: Cr15Mov with quenched treatment

d.Transport: by gear

e. Forming speed: 18-20m/min

f. Motor: 4kw

g. Voltage: 380v, 50Hz,3 phase

h. Structure: independent stand

i. Size of machine: 4.5m *0.8m *1.2m

j. weight:1.8T

Shearing system:

The material of blade: Cr12Mov,

Hardening HRC 58-62℃

Length Tolerance:3m±1.0mm

The punched holes will be done together with the shearing system.

Hydraulic station:

Hydraulic motor Power: 3kw

Hydraulic oil: 46#

Hydraulic pressure: 12 Mpa

Brand: Chinese famous brand.

Components: The system includes a set of hydraulic tank, a set of hydraulic oil pump, and two hydraulic pipes. And two sets of electromagnetism valves.

PLC Control system:

Feature:

Adopted PLC, transducer, touch panel from Mitsubishi Japan to ensure high speed with stability, precision and lifetime.

Other electric element is Schneider

Equipped with movable switch, air break, radiator, transformer & electric leakage protector, that element can make sure easy operation convenience and safety.

Brand: Delta Taiwan brand or Semen Germany brand or Panasonic, Japan brand.

Product Categories : Roller Shutter Door Forming Machine