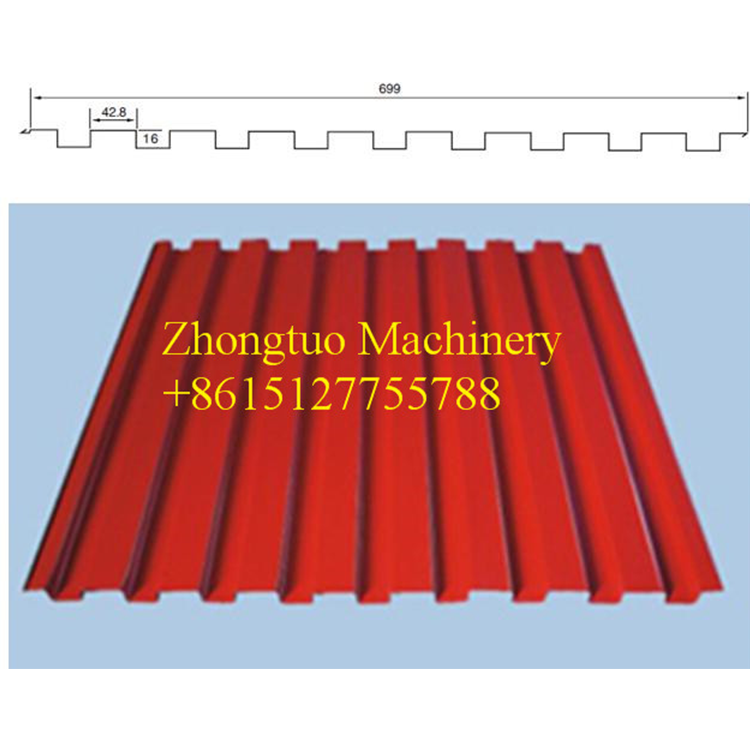

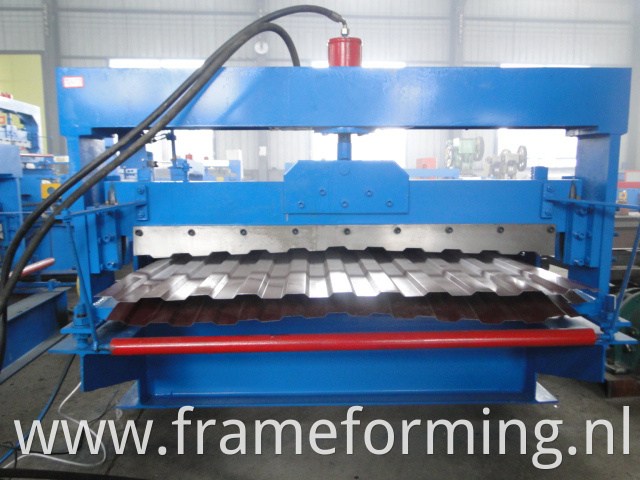

Steel Roller Shutter Door Slat Roll Forming Machine For Australia

Steel roller shutter door has a variety of styles. To meet different customer requirements, we are trying to find the suitable solution. Take the roller shutter door slat forming machine for example, i will introduce more detail information for you.

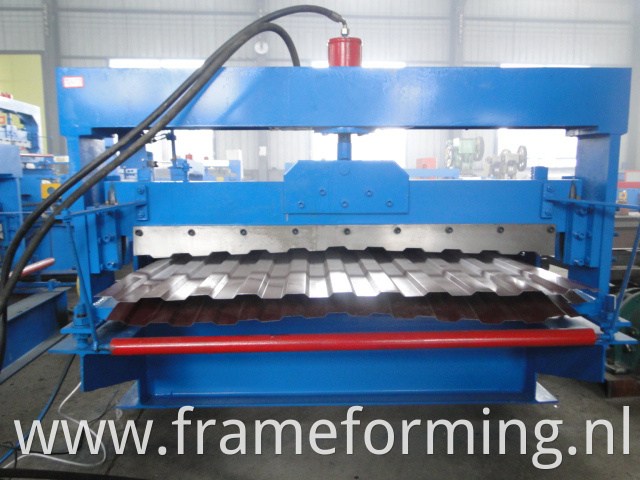

Working flow of steel roller shutter door making machine

Decoilerà leveling systemà roll forming machineà shearing systemà runout table

Main parameter and basic introduction of roller shutter door slat forming machine

Decoiler:

Usage: It is used to support the steel coil and uncoil it in a turntable way.

Passive uncoil pulled by roll forming system

a.Coil inner diameter: 450-550mm

b.Coil max width: 1200mm

c. Max carrying capacity:5000kg

Leveling system of steel roller shutter door making machine:

Entry leveling and punching dots if you need.

This part will level coil to make sure it is neat clean and straight.

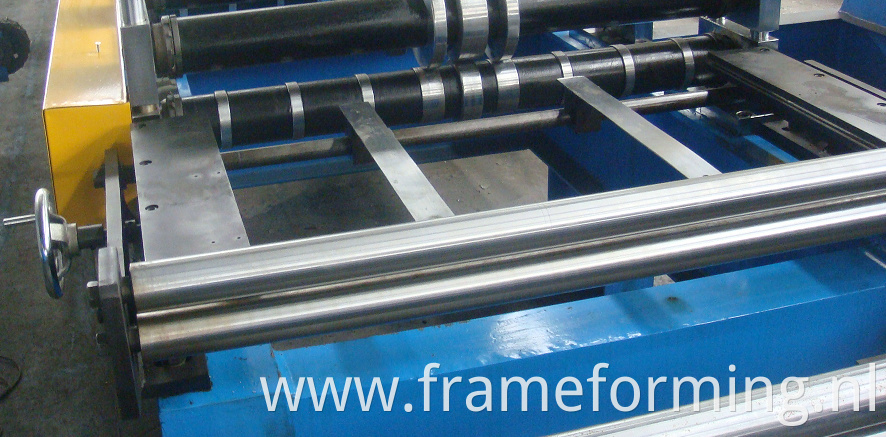

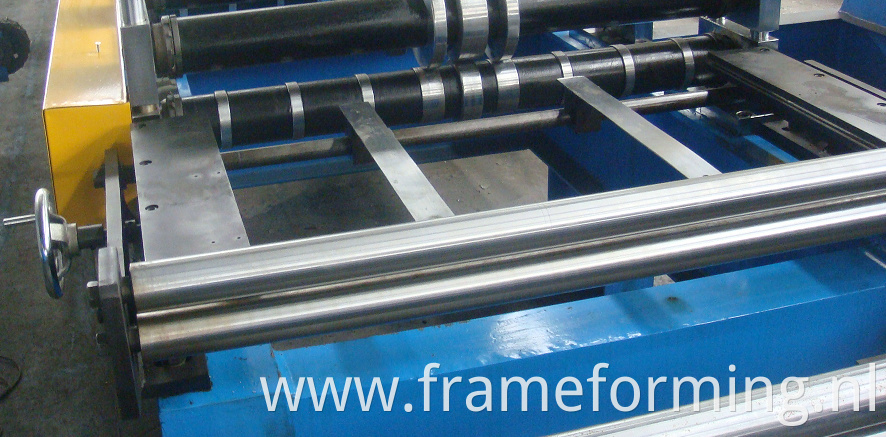

Main roll forming machine system of steel roller shutter door making machine:

a. Number of forming steps: 20 stations

B. Shaft material: 45# steel with quenched treatment, precision machined,

The diameter: ¢70mm

c. Roller material: 45# steel, surface hard chromium plating.

d.Transport: by gear

e. Forming speed: 20-25m/min

f. Motor: 15kw

g. Voltage: 380v, 50Hz,3 phase

h. Structure: independent stand

i. Size of machine:12000х1700х1500

Shearing system for your reference:

The material of blade: Cr12Mov,

Hardening HRC 58-62℃

Length Tolerance:3m±1.0mm

The punched holes will be done together with the shearing system.

Hydraulic station:

Hydraulic motor Power: 5.5kw

Hydraulic oil: 40#

Hydraulic pressure: 12 Mpa

Brand: Chinese famous brand.

Components: The system includes a set of hydraulic tank, a set of hydraulic oil pump, and two hydraulic pipes. And two sets of electromagnetism valves.

PLC Control system:

Feature:

Adopted PLC, transducer, touch panel from Mitsubishi Japan to ensure high speed with stability, precision and lifetime.

Other electric element is Schneider

Equipped with movable switch, air break, radiator, transformer & electric leakage protector, that element can make sure easy operation convenience and safety.

Brand: Delta Taiwan brand or Semen Germany brand or Panasonic, Japan brand.

Product Categories : Roller Shutter Door Forming Machine