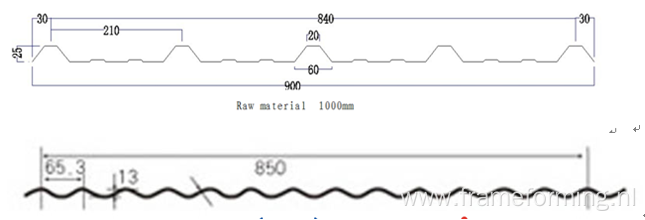

This 1000 metal roof sheet machine Roofing Panel roll forming machine is consisted of a below parts: Decoiler,Entry leveling,Roll forming machine,Shearing system ,Hydraulic station,

5 Ton decoilers

Processing material: colored steel plate, galvanized plate

Material thickness: 0.4---1.2mm

Material hardness: 195 mpa---350 mpa

Forming speed: 8-12m/min

Usage:Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate board.

1.Feature : Ensure stability, precision and cutting speed

2.Function : Automatic cutting controlled by PLC

3.It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

4 .Material of blades: Cr12 quenched

5 .Power supply : hydraulic power

6. Components: It contains one set of blade, one hydraulic tank and one cutter machine.

1. It is controlled by gear pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

2.Power:3kw

3.Hydraulic oil: 46#

4. Components: The system includes a set of hydraulic tank, a set of hydraulic oil pump, four hydraulic pipes. and two sets of electromagnetism valves.

Adopted PLC , frequency converter , Delta fromTaiwanto ensure high speed with stability, precision and lifetime.

One counter gauges length, pulses, and decides length.

Omron encoder for length measurement.

It adopts welded steel and supported roller to transmit the products.

Zhongtuo factory is professinal design different kinds of roofing machine based on customers requirements.Any planning of your roofing sheet, no matter normal roofing sheet, or glazed tile roofing sheet, or stone coated roofing machine, welcome contact me:

Product Categories : Roofing Sheet Roll Forming Machine > Roof and Wall Panel Roll Forming Machine