New 970 steel roof tile forming machine

Materials:

Processing material: colored steel plate, galvanized plate, or aluminum plate

Material thickness: 0.3- 0.8 mm (or as your request)

Coil width:or as your request

Forming speed: 8-12 m/min or as your requests

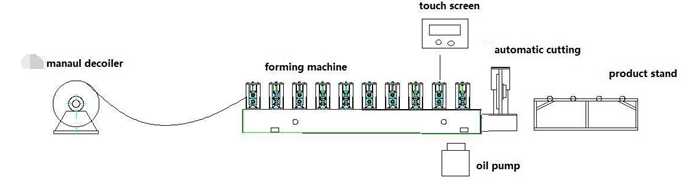

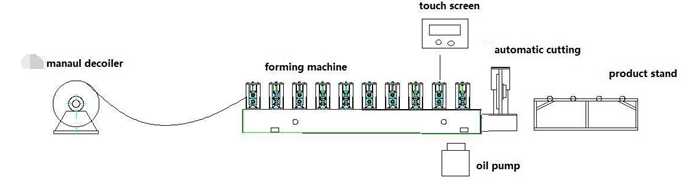

Production process

Uncoiling→Feeding material into machine→Roll forming→Measuring length→

Auto cutting→Products receiving

Components of production line

| No. | Name | Unit | Qty |

| 1 | Decoiler | set | 1 |

| 2 | Main forming machine | set | 1 |

| 3 | PLC control system | set | 1 |

| 4 | Hydraulic pump station | set | 1 |

| 5 | Post cut | set | 1 |

| 6 | Electric motor | set | 1 |

| 7 | Output table | set | 1

|

Detailed introduction of every part for this production line

1.Un-coiler System

Usage: It is used to support the steel coil and uncoil it in a turntable way.

Passive uncoil pulled by roll forming system

| Loading capacity | Uncoiling width | Inner diameter |

| 5T | 1200mm | 450-550mm |

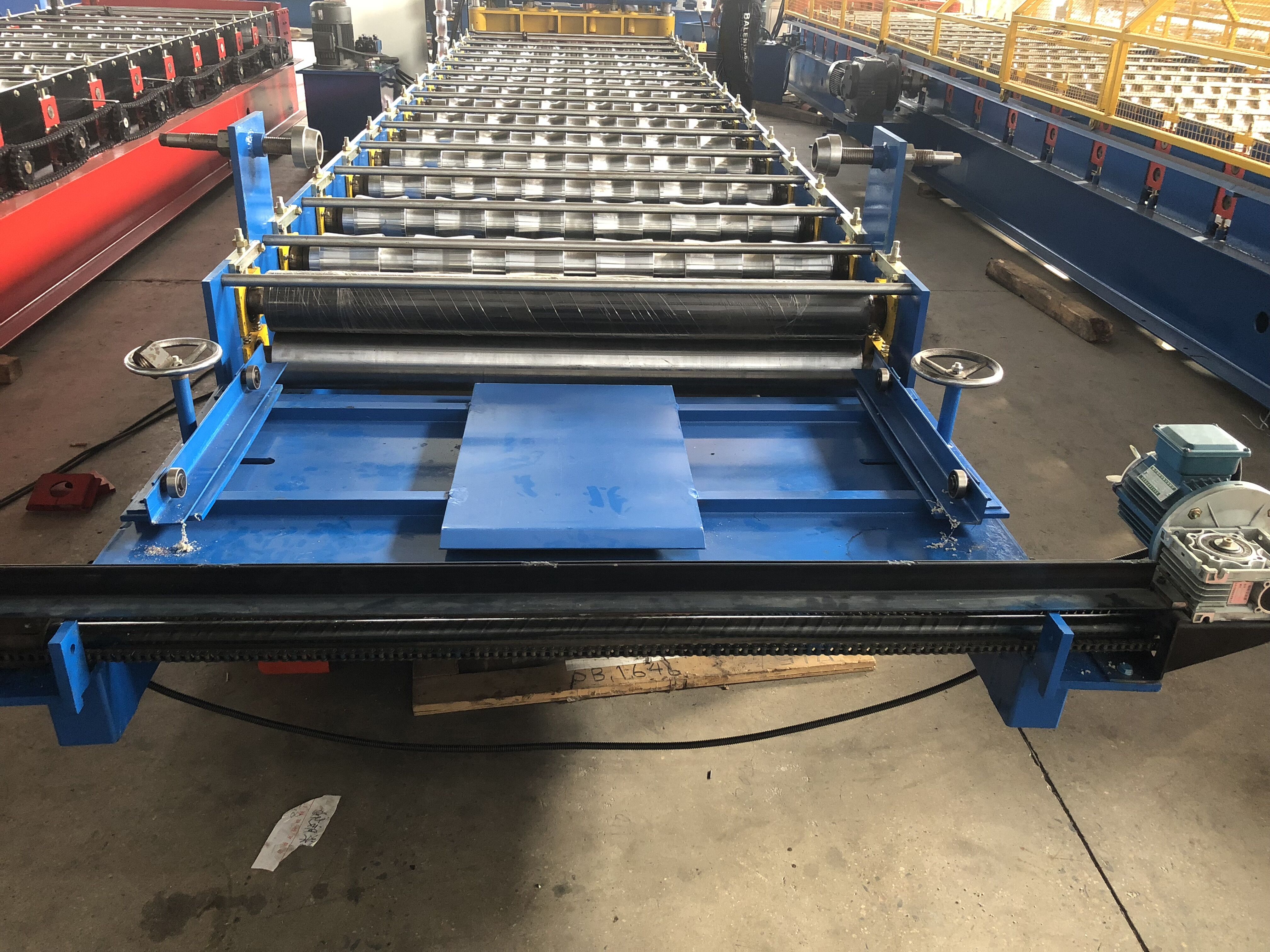

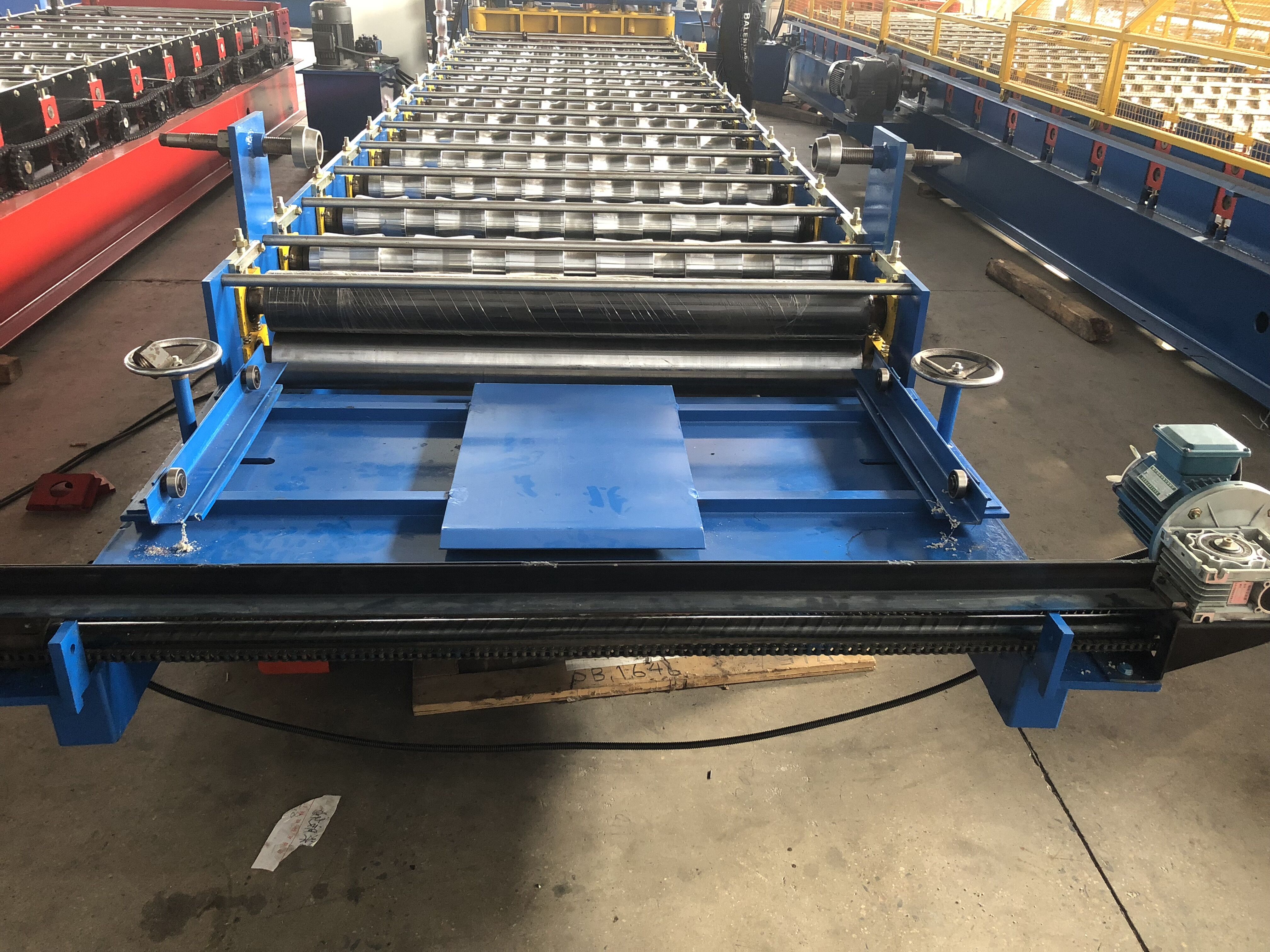

2. Coil feeding part

Usage: Put the raw material(steel plate) through the beach to manufacture and process,it can guarantee that the products are neat,parallel and everything is uniformity.Please refer to the equipment regulation to know the function of locate angle iron.

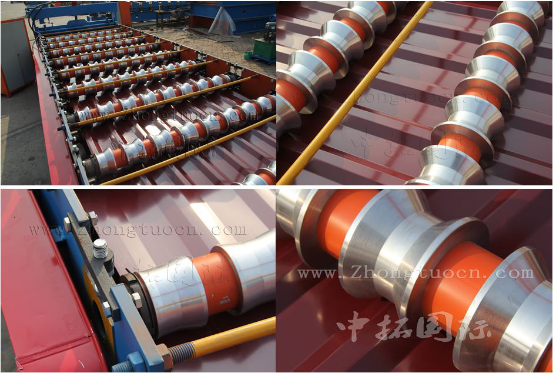

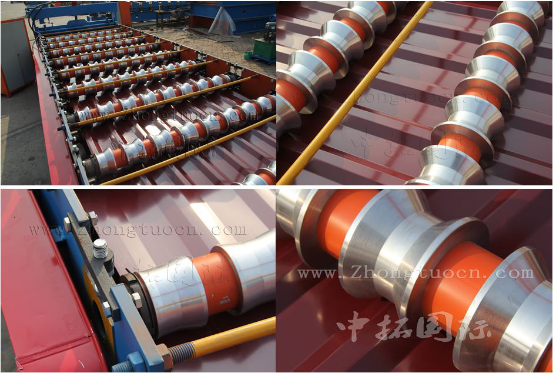

3. Main Roll Forming System

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive,chain transmission,roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is working.

Feature : Ensure stability , precision and lifetime.

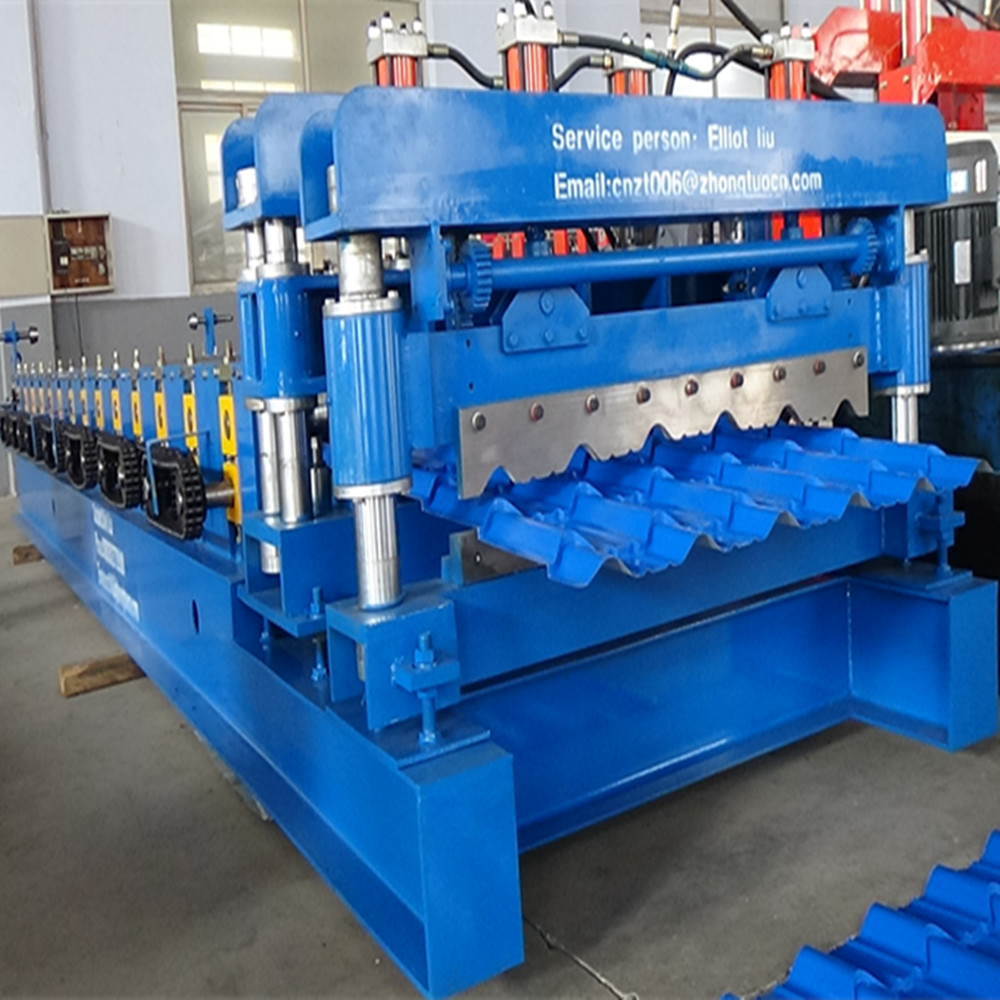

Feature : Ensure stability, precision and cutting speed

Function : Automatic cutting controlled by PLC

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: Cr12 quenched

Power supply : hydraulic power

Components: It contains one set of blade, one hydraulic tank and one cutter machine.

Feature : Ensure stability, precision and cutting speed

Function : Automatic cutting controlled by PLC

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: Cr12 quenched

Power supply : hydraulic power

Components: It contains one set of blade, one hydraulic tank and one cutter machine.

some pics for your reference:

The advantage of New steel roof tile machine:

1.Good quality: We have a professional designer and experienced engineer team.And

the raw material and accessories we use are good.

2.Good service: we provide the technical support for whole life of our machines.

3.Guarantee period: within one year since the date of finishing commissioning. The guarantee covers all the electric, mechanic and hydraulic parts in the line except for the easy-worn parts.

4.Easy operation:All machine cotrolling by PLC computer controlling systerm.

5.Elegant apperance:Protect the machine from rust and the painted colour can be customized

6.Reasonable price:We offer the best price in our industry

Product Categories : Roofing Sheet Roll Forming Machine > Roof and Wall Panel Roll Forming Machine