ERW high frequency iron pipe machine,Pipe Making Machine

Basic information of ERW high frequency iron pipe machine:

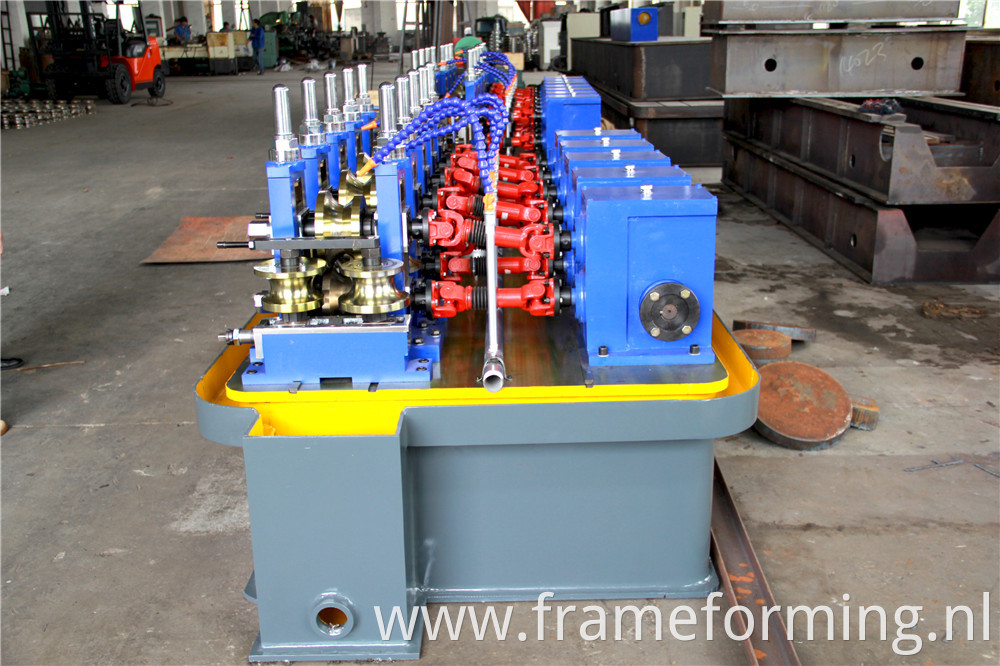

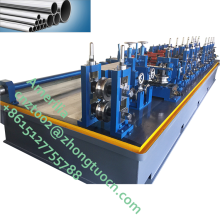

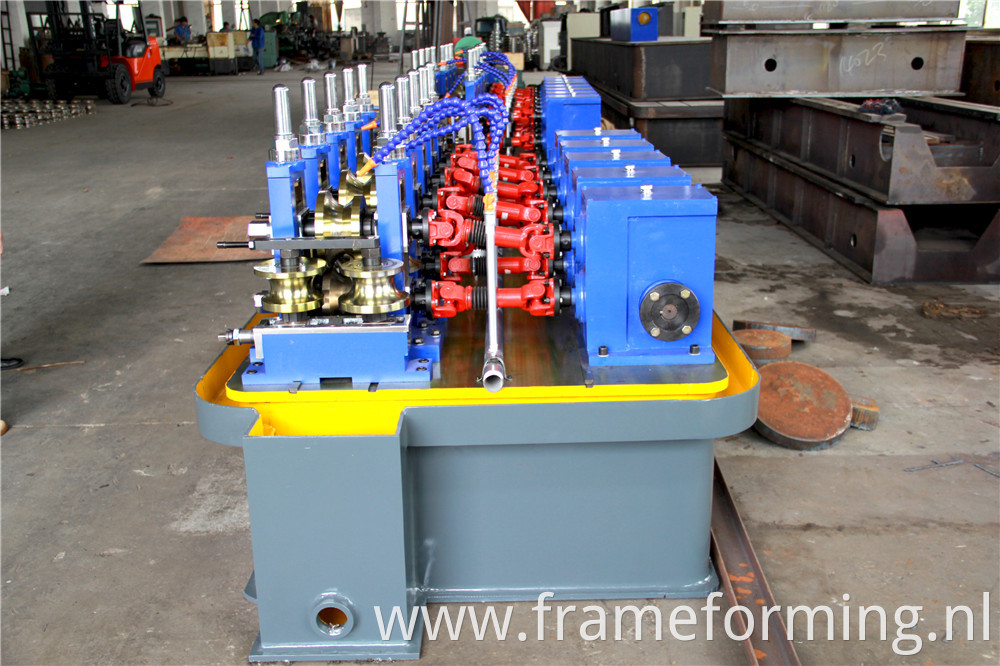

Zhongtuo Welded Pipe Machine adopts advanced welding technology and offers dual welding arcs, increased speed, higher deposition, superior mechanical properties and quality. HG50, HG79 high frequency welded pipe machine is widely applied for producing tubes for heat exchanger, refrigerator, frame of car, bicycle, fitness equipment, furniture, cooling machine, petrol transmission, construction industry, etc. This high frequency Welded Pipe Making Machine or Welded Pipe Mill composes of a complete set of pipe forming machine, rotating capstan, decoiler, straightening machine, shearing,accumulator, tube mill section, flying saw and packaging device. Now we have four types machines which are divided by wall thickness and diameter.

Specification of steel pipe machine HG50:

1. Pipe diameter: Ø10–Ø60mm

Pipe Thickness: 0.5– 3.0mm

2. Square Pipe: 10X10mm –60X60mm

Rectangle Pipe: 20X40mm –40X60mm

Pipe Thickness: 0.5 –3.0mm

3. Pipe Length: 6-12m

4. Length Tolerance: 0-6mm

b) SteelTape Specification

1. Material: Low Carbon steel (σb≤500Mpa,σs≤235Mpa)

2. Steel Tape: Inner diameter: Φ470-Φ510mm

Outer diameter: Φmax=1500mm

Strip steel width: 40mm-240mm

Strip steel thickness: 0.8mm-3.0mm

The maximum weight: 2.0 tons

c) Electricity

1. Dynamic power: AC380V±10%, 3phases, 50Hz±1.0%

2. Control Power: AC220V±10%, one phase, 50 Hz ±1.0%

d) Electric installed capacity: appro. 250KW

e) Cooling water

1. Reservoir for High Frequency equipment: 15 m³, one set

2. Reservoir for circulating cooling water: 15 m³, one set

IV. Equipment makeup and main parameters of single unit:

1. Double-head un-coiler

1.1. Briefing: Rotary type to change coils easily, with a pneumatic brake

1.2. Parameters:

- Coil width: max.240mm

- Coil OD: max. Ø1500mm

- Coil ID: Ø 470- Ø 510mm

- Coil weight: max. 2.0 tons

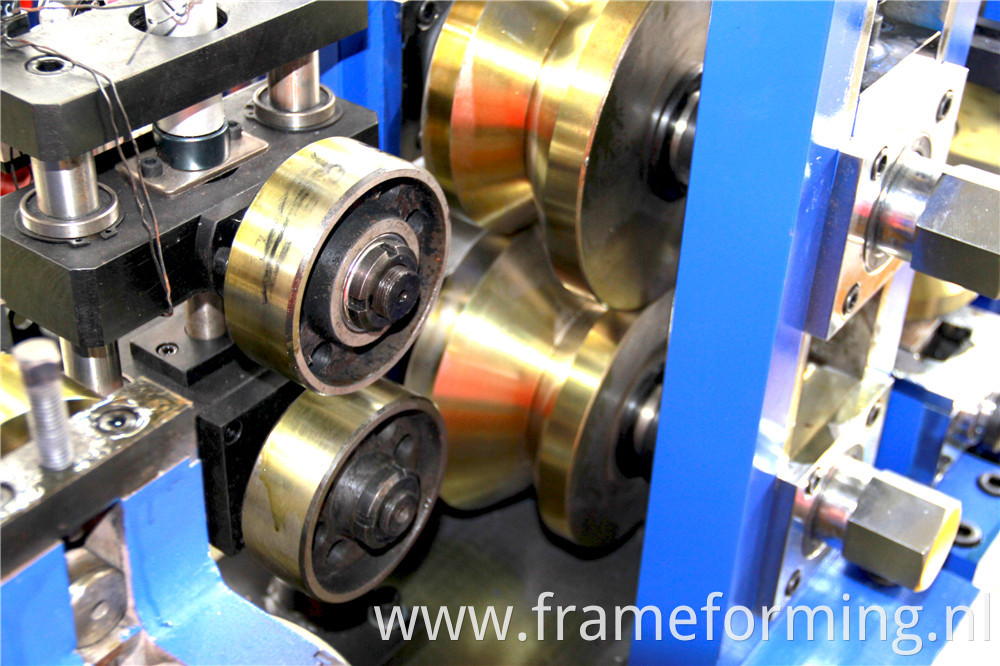

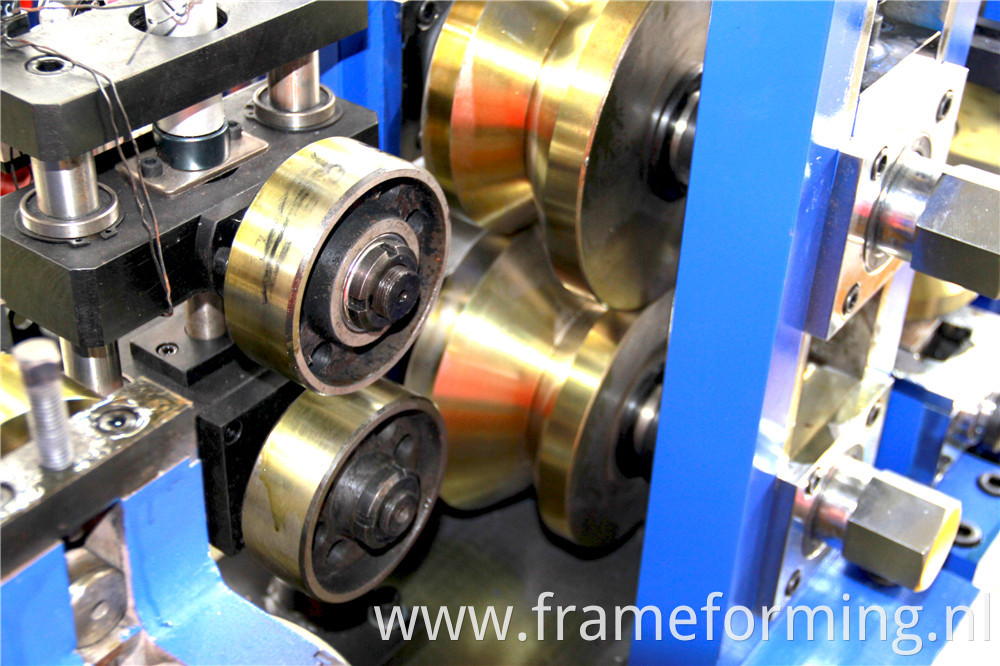

4.1.2 Welding pipe machine Forming mill consists of:

- Driven stand: 7 sets (Horizontal)

- Driven stand shaft: Ø60mm

- Material of shaft: 40Cr

- Side roll stand: 8 sets(Vertical)

- Side roll stand shaft: Ø40mm

- Material of shaft: 40Cr

- Gear box & universal joint: 7 sets

- Material of gear box: cast steel

- Material of gear: 20CrMnTi

- Main motor: 55kW model: Z4-200-31 1 set

- Main redactor: ZLY224 1 set

4.2 Sizing mill gear box, universal joint

4.2.1 Sizing mill consist of:

- Driven stand: 5 sets (Horizontal)

- Driven stand shaft: Ø60mm

- Material of shaft: 40Cr

- Side roll stand: 5 sets(Vertical)

- Side roll stand shaft: Ø40mm

- Material of shaft: 40Cr

- Gear box & universal joint: 5 sets

- Material of gear box: cast steel

- Material of gear: 20CrMnTi

- Main motor: 55kW Model: Z4-200-31 1 set

- Main redactor: ZLY224 1 set

- 2 sets single head Turk`s head, with 4 rollers*2sets

- One speed testing roller with air cylinder for CNC flying saw

Product Categories : Welded Tube Mill > Welded Pipe Machine