Roof Truss Making Machine

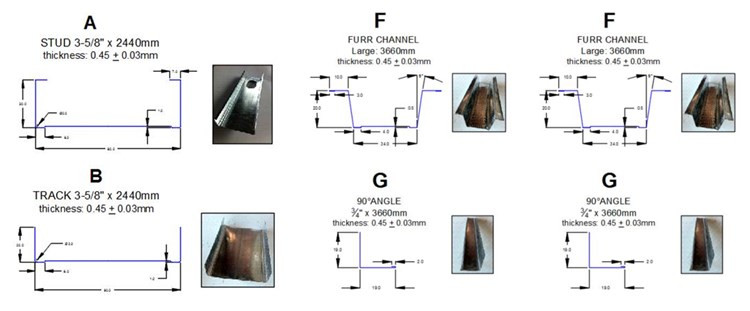

Roof Truss Making Machine can produce many kinds of keels ,such as C-shape,U-shape,L-shape,Omega-shape and T-bar.Double line high speed stud Roll Forming Machine can produce any two or them. The products can be used as the main force structure of medium-sized industrial and civil buildings ,such as factories, warehouses, garages, exhibition halls, theaters, stadiums.

advantages of Roof Truss Making Machine

1.PLC Control

You can add in-Line Printing, and PC-Controller Software allowing you to lable components and control your machine from your computer. Each option may be included with your machine or added later as your needs evolve

2.Holes

All our machine can be set-up with a Service Hole, Dimple Punch, Index/Bolt Hole and Web-notch tools.

3.high speed

Servo driven punch provides close tolerance accuracy and none stop punching for increased production, with interchangeable tooling for different hole sizes and shapes.

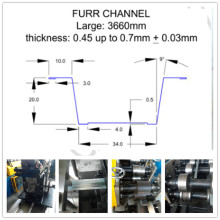

we can design as your profile drawing ,or we can recommend you some popular types in your area.

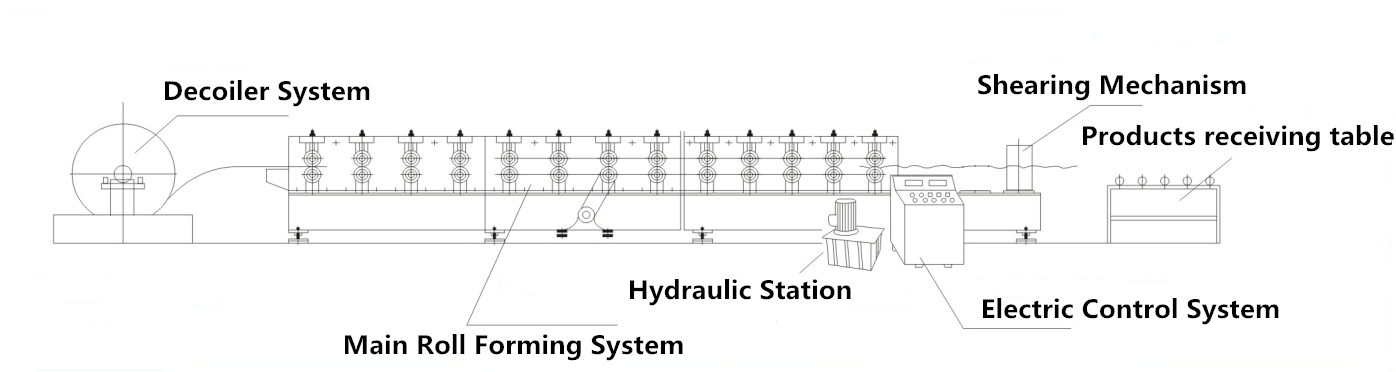

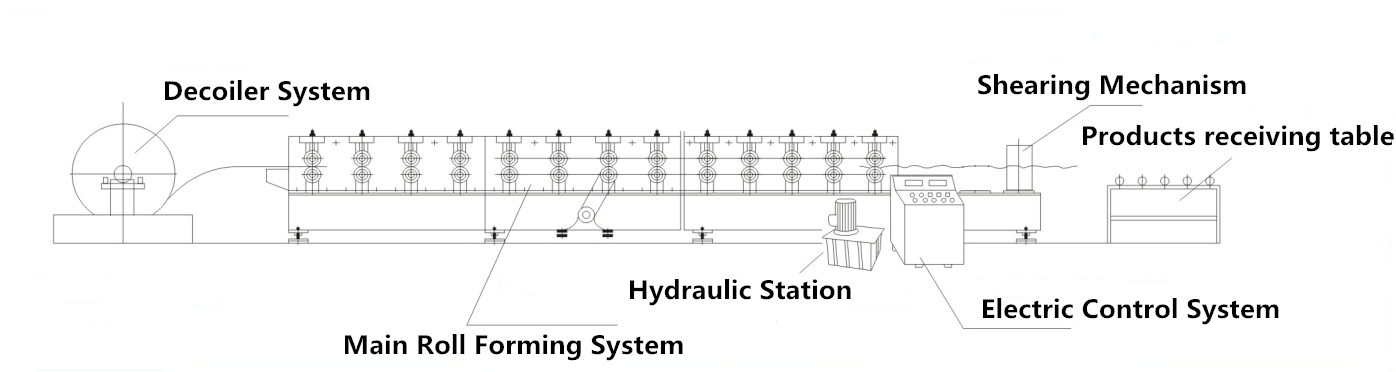

Roof Truss Making Machine is composed of the following parts: Manual Decoiler, feeding and flatting system,( 57030403,punching device,) main roll forming machine,cutting device, hydraulic station, PLC control system and receiving table.

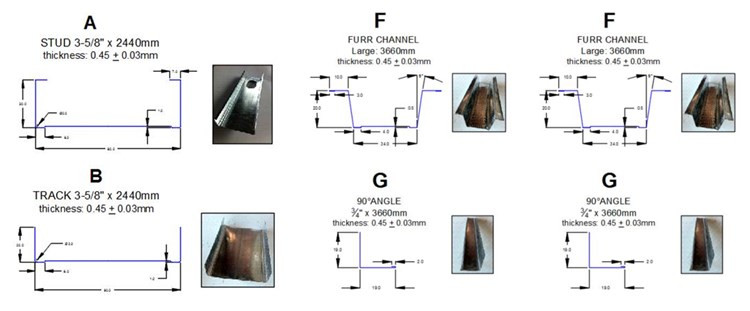

technical parameters of Roof Truss Making Machine

Decoiler

Usage: It is used to support the steel coil and uncoil it in a turntable way. Passive uncoil pulled by roll forming system

Loading capacity: 3T

Uncoiling width: 500mm

Inner diameter: 450-550mm

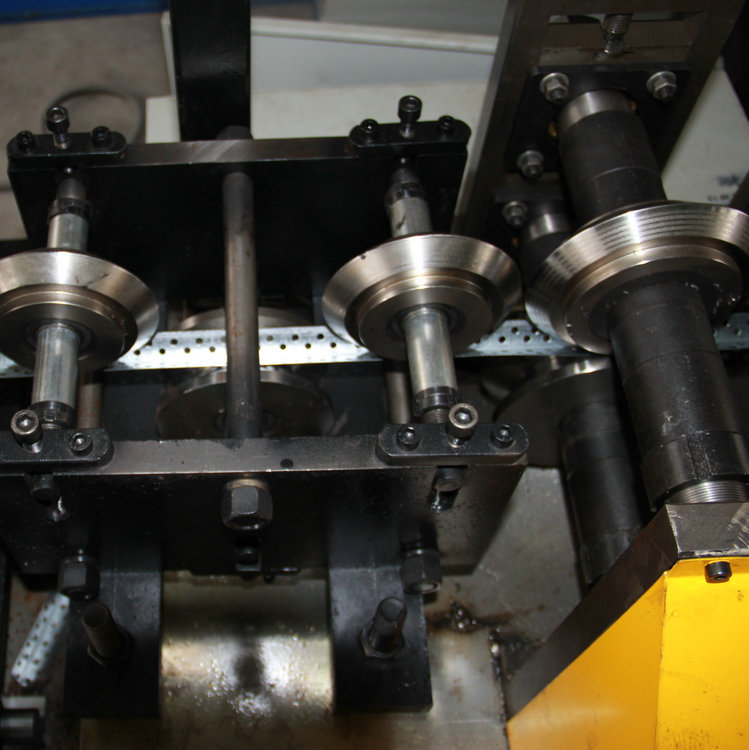

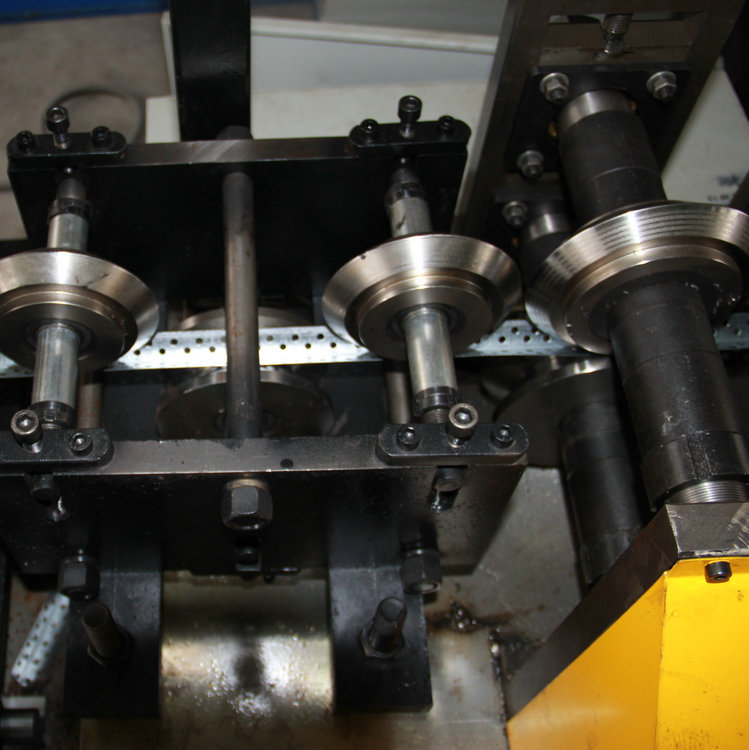

Main metal stud and track roll forming machine:

Feeding and flatting will make sure the steel is neat clean and straight.

Roller fixer : Guide column

Frame : middle plate welded Memorial arch frame type

Diameter of shafts: φ40mm

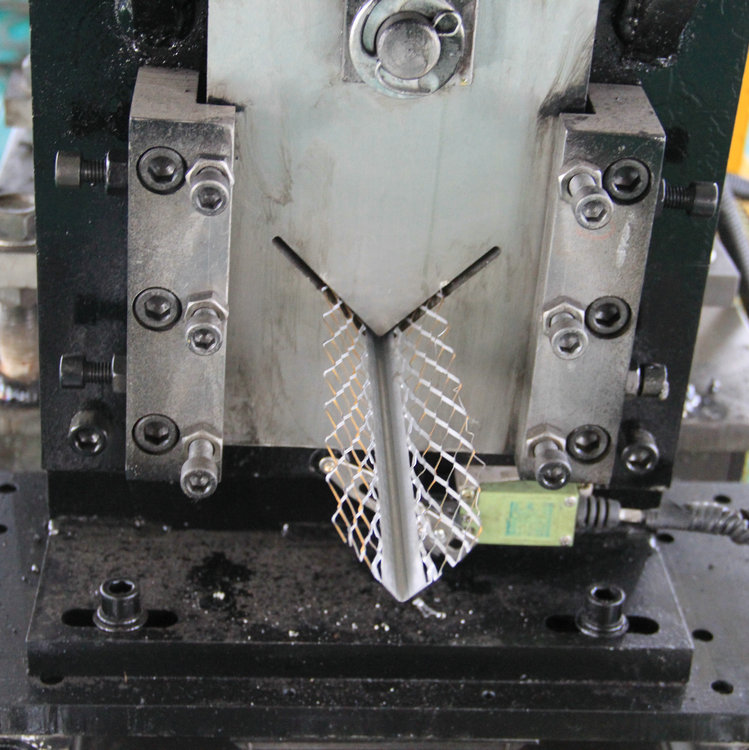

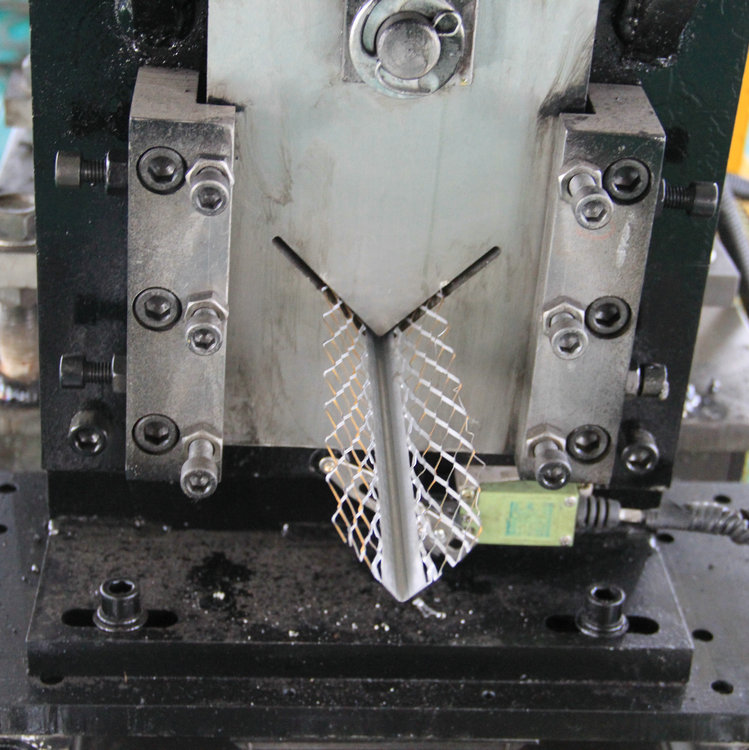

Shearing Machine:

Power : hydraulic

Frame : Pillar style with rack & pinion system

Stroke switch : non-contact photoelectric switch

Electic Control System:

1. Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.

2.Other electric element are Delta

3. Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety.

additions:

Sometimes there are some embossing and holes on our customers samples. For the holes, a punching device must be added. For embossing ,we usually put the embossing model on the former rollers .If you want your logo to be printed an the keel,we have two methods.One ,the same as getting holes ,add a logo punching system in front of the hydraulic station.Or we make some changes on the rollers.Then you can get your logo while roll forming.

After sale Service

a.One year guarantee for whole machine.

b.24 hours technical support by email or calling.

c.If there is any problem found in ourmachine, we will repair it for free in one year.

Product Categories : C/U/ Channel & T Bar Roll Forming Machine > Ceiling Channel Roll Forming Machine