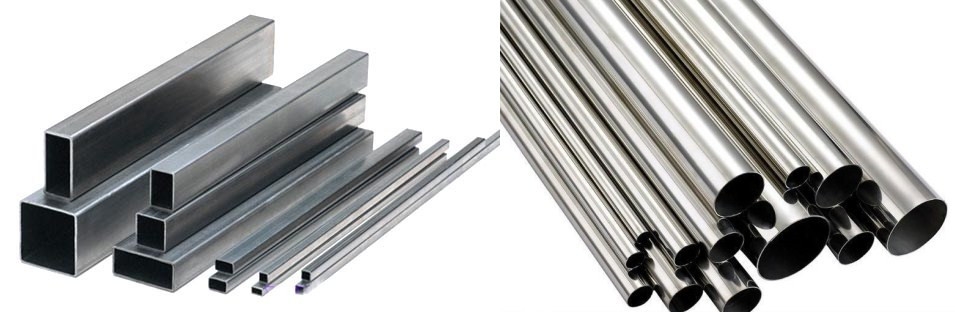

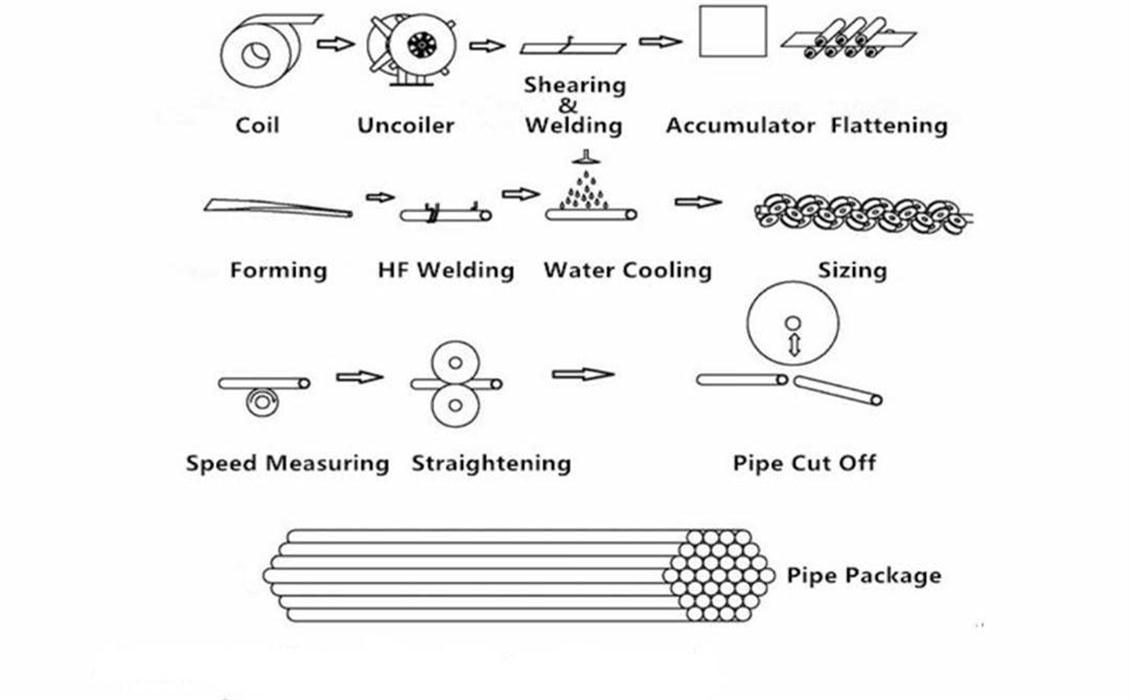

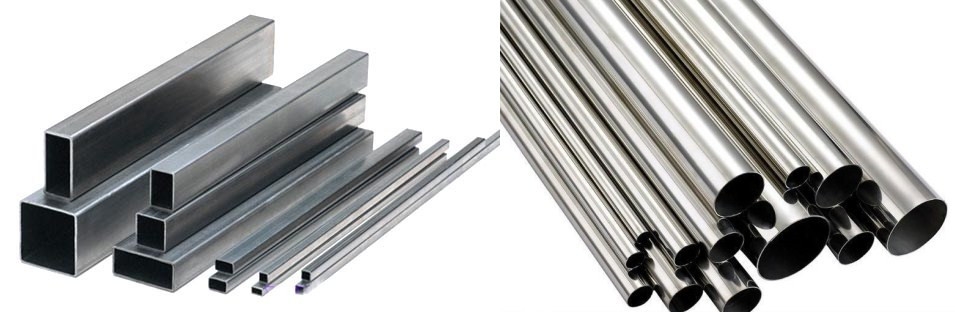

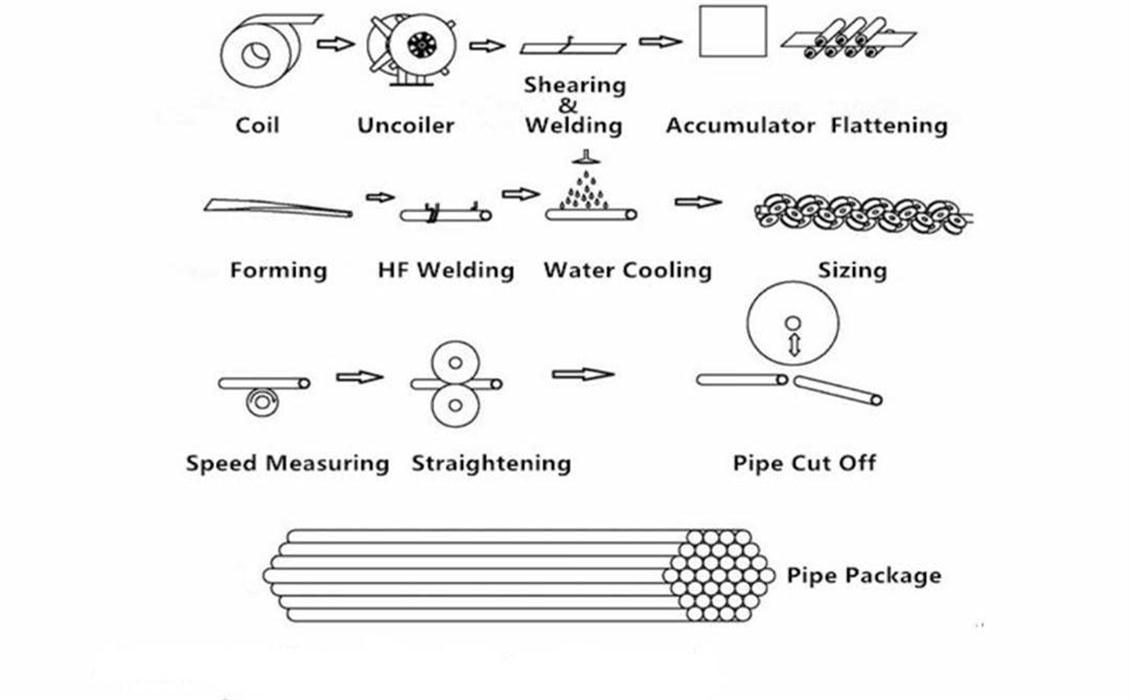

Our High Frequency Welding Tube Mill is intended for manufacturing of round pipe of Φ16mm-Φ127mm with thickness of 0.5 mm–5.0 mm from cold-rolled and hot-rolled coil strip by means of unclosed tubular blank with its subsequent welding into tube, edge heating by means of solid state high-frequency welder, longitudinal seam welding in rolls of tube welding machine, cooling, further sizing or shaping and on-stream cutting of endless tube in measured lengths.

Finished product can be of round, square or rectangular pipes.

a) High Frequency Welding Tube Mill Specifications: Pipe diameter: Ø16–Ø127mm Pipe Thickness: 0.5– 5.0mm Pipe Length: 6-9m Length Tolerance: 0-3mm

b) High Frequency Welding Tube Mill Steel Tape Specifications: Material: Low Carbon steel (δb≤500Mpa, δs≤235Mpa) Inner diameter: Φ580-Φ610mm

Outer diameter: Φ900-1500mm Strip steel thickness: 0.5mm-5.0mm The maximum weight: 5.0 tons

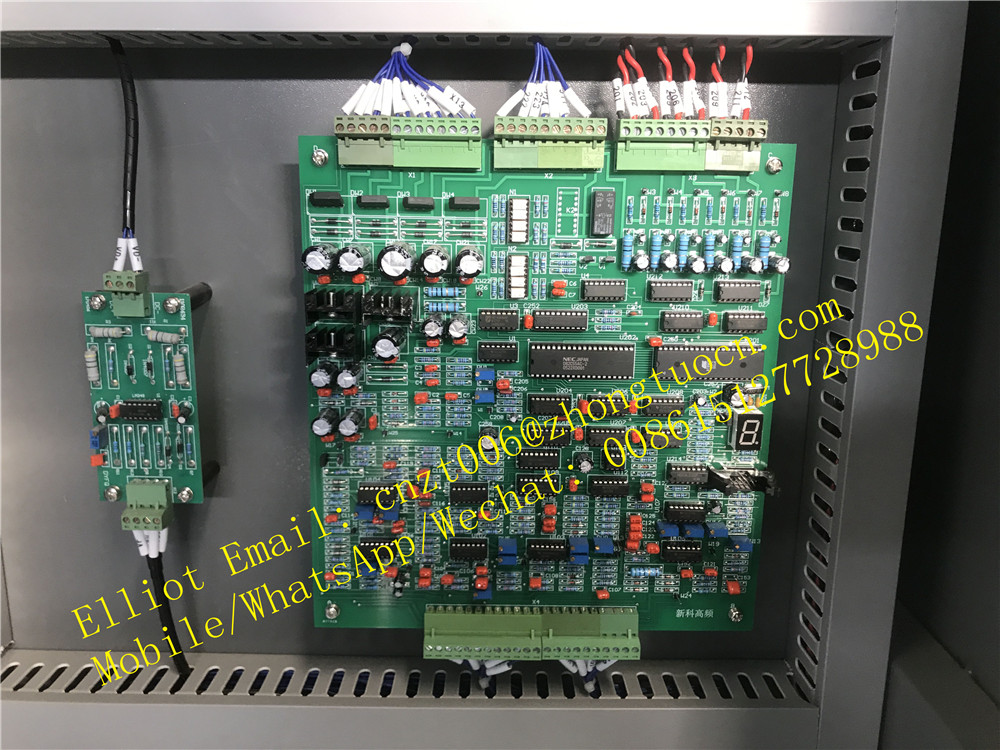

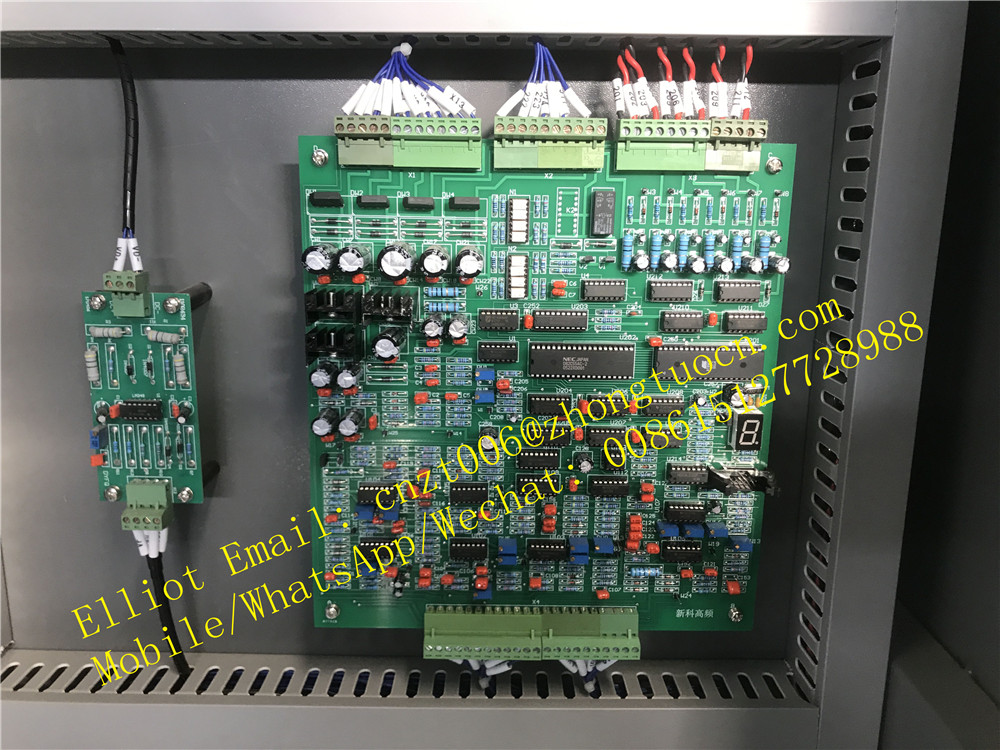

c) High Frequency Welding Tube Mill Electricity: Dynamic power: AC380V±10%, 3phases, 50Hz±10% Control Power: AC220V±10%, one phase, 50Hz ±10% Electric installed capacity: appro 450KW

e) High Frequency Welding Tube Mill Cooling water: Reservoir for High Frequency equipment:15 m³, one set Reservoir for circulating cooling water:15 m³, one set f) High Frequency Welding Tube Mill Compressed air: Pressure: 0.4Mpa Flow: 0.5m3/h g) High Frequency Welding Tube Mill speed:

30-90m/min

Why choose to cooperate with us ? 1. We are professional manufacturer, so we can offer better price and after-sale service and shorter delivery time. 2. We have strong design & technical ability, we can design and manufacture as customer's requirement. 3. Our factory has been approved ISO 9001 certificate. 4. We have much experience for installation and training experience overseas. 5. We have successfully exported our machines to more than 90 countries, We all get good feedback. 6. We provide a free two years warranty for all our items.

Why choose to cooperate with us ? 1. We are professional manufacturer, so we can offer better price and after-sale service and shorter delivery time. 2. We have strong design & technical ability, we can design and manufacture as customer's requirement. 3. Our factory has been approved ISO 9001 certificate. 4. We have much experience for installation and training experience overseas. 5. We have successfully exported our machines to more than 90 countries, We all get good feedback. 6. We provide a free two years warranty for all our items. 7. OEM brand.

High Frequency Welding Tube Mill FAQ: 1.How to get a quotation of tube rolling line ? Give me the diameters and thickness for the pipe . Other spicific requirements is welcome, such as the speed,power and voltage you want. 2. Terms of payment ? 30% T/T, Balance to be paid before shipping after inspection.Also we accept the payment L/C, O/A , D/P.

3. What is your after-sale service ?

High Frequency Welding Tube Mill warranty period is 24 months, if the broken parts can't be repaired, we can send new to replace for free, but you need to pay the express cost yourself. we supply the technical support for the whole life of the equipment.

4. How to visit your factory ?

a.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour), then we can pick up you. b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.