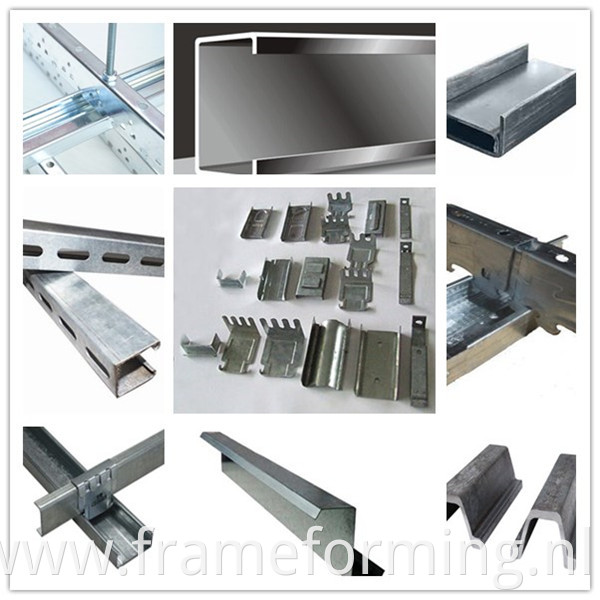

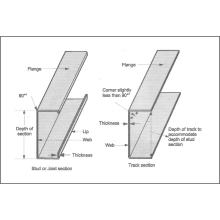

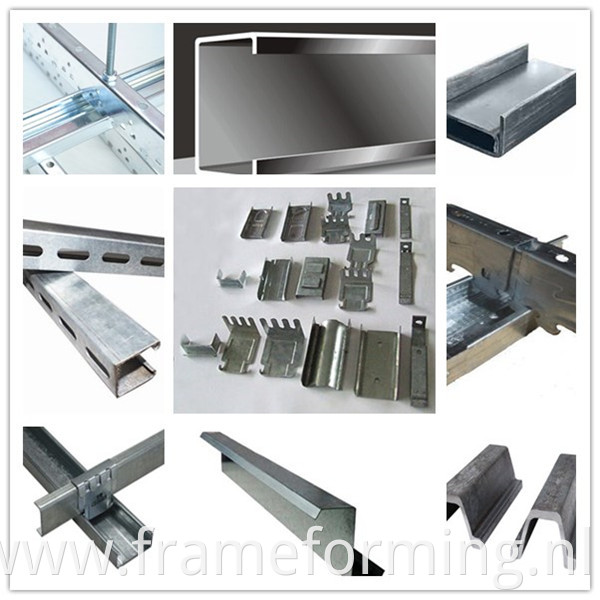

Our machine can produce many kinds of keels.The products can be used as the main force structure of medium-sized industrial and civil buildings ,such as factories, warehouses, garages, exhibition halls, theaters, stadiums.

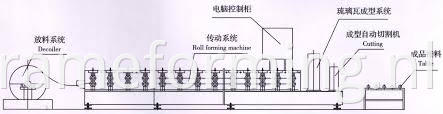

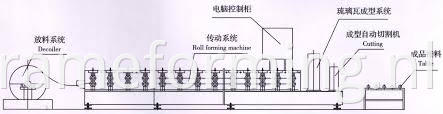

Processing flow diagram of machine

Manual Decoiler→Feeding material into machine →Roll forming machine →Measure length →Hydraulic cutting →Finished Products

decoiler

inner Diameter 450-550mm

Outer Diameter max 1500mm

Max Coil width 500mm

Capacity 3T

main forming machine

Forming steps 12 rollers

Design type Guide column

Machine frame Memorial arch

Changing size methods Completely changing the mold linear system

Structure independent stand

Power of main machine 7.5 kw

Type of cutting and punching Hydraulic

Hydraulic servo tracking cutting

the machine is with servo tracking cutting, the cutting knife can move automaticly. so that, the tracking cutting can keep same speed with the main forming machine, and cut the finished products continually .

| No. | Name | Size and mode | number | note |

| 1 | base frame | 100*100*6 | 1 | |

| 2 | Control station | | 1 | Include switch button |

| 3 | Hydraulic station | 4kw | 1 | |

| 4 | Oil pump | 63*80*80 | 1 | |

| 5 | Cooling device | 35Hz | 1 | |

| 6 | Sensor | Npu | 2 | |

| 7 | Encoder | 600 | 1 | Omron |

| 8 | tachometric wheel | | 2 | |

| 9 | Servo motor | 3.9kw | 1 | GSK |

| 10 | Mold | Mulfan1 | 4 | |

| 11 | Lead screw | Sfu4020-1230 | 1 | Taiwan |

| 12 | Guide | HG35-2000 | 2 | |

| 13 | Slider | HGH35cA | 4 | |

| 14 | Coupling | | 4 | |

Shearing Machine:

Material of blades: Gcr12 quenched

Power supply : hydraulic power

Frame : Pillar style with rack & pinion system

Stroke switch : non-contact photoelectric switch

Electic Control System:

1. Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.

2.Other electric element are Delta

3. Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety.

additions

If you sample is with the perforated holes or the mesh on the profile, then it need the press punching system. The there is a hydraulic tracking cutting system at the end of the roll forming machine body. The cutting can be designed as the high speed one and the normal speed one. Also there can be designed a logo punching system together with the cutting system, it can be name the non stopping punching and cutting system.

Product Categories : C/U/ Channel & T Bar Roll Forming Machine > Drywall Profile Roll Forming Machine