steel downspout forming line

The usage of the Round steel downspout forming line for Rainwater Pipe as below:

Collecting roof rainwater, belonging to the falling water system components, concentrated lead to the ground below the laying of the rain pipe.

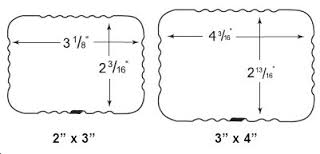

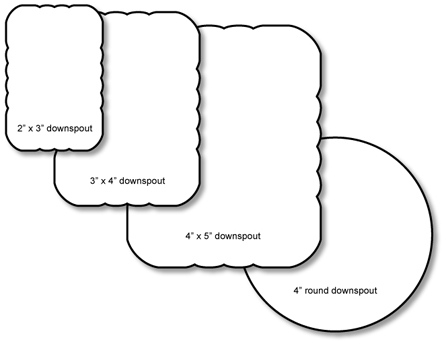

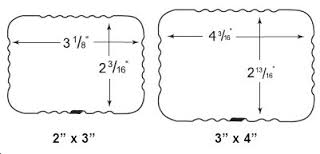

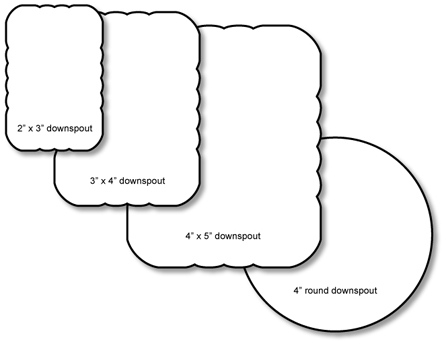

For the material, there are steel material and plastic material. There are round shape and square shape. For the sizes are as below:

Round pipe as : 40mm, 50 mm,75 mm,90mm ,110mm ,150 mm,200 mm,250 mm, 315 mm,400 mm,500 mm and so on.

The square pipe size as below:80mm*55mm,80mm*63mm,80mm*100mm and so on.

Our factory professional make the cold roll foring machine for the Downspout.

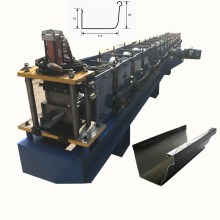

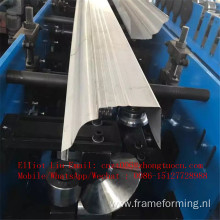

The Rain Water Pipe Machine pictures are as below:

The Round rainwater down pipe manufacuring machine is as below:

Control System PLC Control Touch Screen

Main Frame 20mm steel welding

Main Power 5.5 kw

Power Supply 380V, 3-Phase,50Hz or any

Forming Speed 12-14m/min

Roll Station 16 stands

Shaft Diameter 65mm

Feeding Thickness 0.5mm

Roller material 45# steel

Below is the business iterms

1) What is the guarantee coverage? What does it include? Is there any possibility of broadening the guarantee time by paying an amount of money?

1 The free warranty is 2 years , and with All life technical guidance for free.

2 We can offer the paid parts after one year, including all machine parts.

3 Ordinary, our machine can not broken in ten years or more, so there is no need by paying an amount of money.

The easy broken parts of machine is : 1 Some parts of Hydraulic system, 2 some parts of electric system, 3 some parts of transmission system, 4 some parts of cutting system, so we will delivery some spare parts of this easy broken parts for free when delivery the machines

Questions 2:

2) Can we have estimated costs of the enterprise start? (installations, technical support, supplies such as batteries and oils or anything the machine needs to run)

1 The machine is completely finished before deliverying to you. When the machine arrived at your factory, all the machine need is the hydraulic oil, gear oil , power supply, electric wire, together this is less than USD 5000.

3) What is the production capacity in terms of units?

Every machine production capacity is 0-60 meters/Min

Questions 3:

4) What are the electricity specifications?

The electricity is 380 V, 60 HZ, 3 Phrase

(The electricity can be customized made according to your require)

Questions 4:

4) What are the additional requirements of the machinery (oil, batteries)?

The additional requirements of the machinery is oil, the oil pump need the oil.

The oil specification is: 46# hydraulic oil, gear oil

Questions 5:

5) What does the customer service include: maintenance plans, machinery parts, etc?

The maintenance is for all life, but the customer side need to pay the Accommodation , transportation, and some salary payment for the Engineer.

Ordinary, this case is few, often, the small problem can be solved by communicated through Email, or calling, we keep every machine documents in the technical department, so we are clear about every machine .

Questions 6:

2) What is the estimated life of the machinery?

The estimated life of the machine is 15-20 years or more.

Questions 7:

3) What is coil width and thickness to produce our profiles?

The feeding coil width can be offered to you in the machine operating manual book when the machine is finished.

The thickness of the strips is : 0.3-0.8 mm (as customer required)

Questions 9:

4) Can the machinery knurl the profiles?

The machine can knurl the profiles with any content or logo symbol,

It need to add a punching press part before the cutting system.

Product Categories : Gutter & Downspount