Perforated U Lintel channel for Roll Forming Machine With punching holes

3. Technical parameters

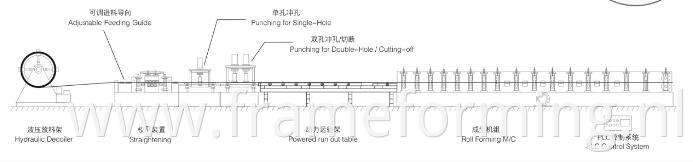

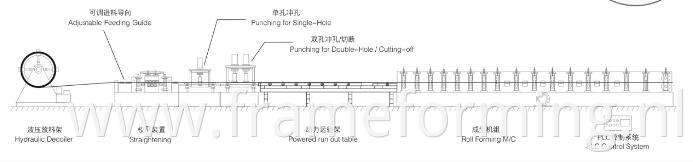

| Configurations | Manual Decoiler, guiding platform,punching machine,main machine of roll forming, cutting device, electric motor,hydraulic station,Delta PLC control system, run out table |

| |

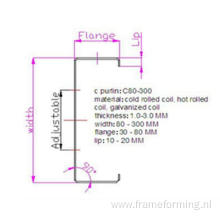

| Material | Raw material | Galvanized |

| Thickness | 1.0-2.5mm |

| |

| Manual decoiler | Inner Diameter | 450-550mm |

| Outer Diameter | max 1500mm |

| Max Coil width | 500mm |

| Capacity | 3T |

| Leveling Part | Put the raw material through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate iron panel. |

| Punching system | Punching Press | Electric press |

| Material of rollers | GCr12MoV |

| Tolerance | ±2mm |

| Constitution can-be welded, composition need to bolt. |

| Roll forming system | Feature | Ensure the stability, accuracy and long life |

| Size | 12m*1.8m*1.5m(L*W*H) |

| Weight | 16 Ton |

| Voltage | customize by customer. |

| Method for fixing roller | arch type. |

| Material of shafts | 400# I-beam |

| Transmission method | gear box |

| The main shaft material | No. 45 steel quenching and tempering treatment |

| outer shaft diameter | 90mm |

| Wheel material | quenching process of GCr15 bearing steel HRC58-60 |

| Roller | 20 stations |

| The main motor power | 22kw |

| |

| Hydraulic System | Hydraulic oil | 46# |

| Hydraulic power | 5.5kw |

| Components | The system includes a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes. and two sets of electromagnetism valves |

| Control Device | Control | By PLC |

| PLC language | As required |

| Touch screen | Delta |

| Function | Automatic length and quantity measurement |

| |

| Other part | Runout table | 60*40mm welded, length could adjustable. |

| Easy damaged parts | conk 2 pcs, fuse-link 4 pcs |

| Rubber mat | 1 pcs; |

| Bolt spanner | 1 pcs |

| Counter | A counter measure length, pulse and the length is determined. OMRON encoder to measure the length. |

| Payment terms | Payment: 30% T/T in advance and balance 70% after inspection confirmation before shipment. Delivery: within 2 weeks working days after receipt of deposit. |

| Warranty | 1. One year, and we will provide the technical support for the whole life. 2. Training: the buyer should charge of visa, return ticket, food and accommodation overseas and USD80 / person/day for salary. 3. Need one technicians 4. Training time: one week (contains the time of installation and adjustment) |

This Perforated U Lintel channel for Roll Forming Machine With punching holes capacity is 6-15 meters/min, Because the holes are very dense, the machine need separate punching holes machine. The holes are pressed by punching machine before feeding into the roll forming machine to form the U channel. This machine is made from manual decoiler, guiding platform,punching machine,main machine of roll forming, cutting device, electric motor,hydraulic station,Delta PLC control system, run out table

Product Categories : C/Z/U Purline Roll Forming Machine > Purline Roll Forming Machine