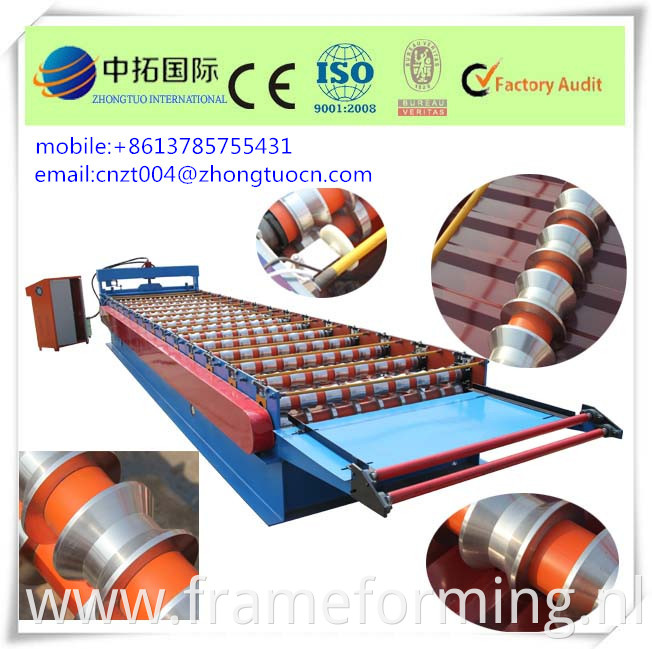

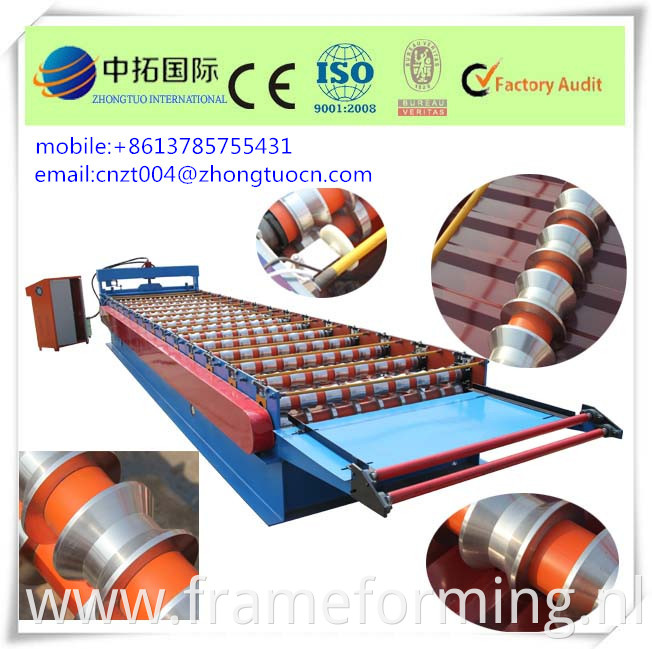

Metal Roofing Wall Sheet Panel Roll Forming Machine

The metal sheet made by metal roofing wall sheet panel roll forming machine are widely used building appliances and transportation and some other industries.

For construction, It mainly used for steel plants, airports, warehouses and freezing and other industrial and commercial building as roofs, walls and doors,

| Machine Description | Qty | Delivery time | Container Type | Price |

| Metal Roofing Wall Sheet Panel Roll Forming Machiner |

1 SET | 30 working days After receiving deposit |

One 40GP | FOB Tianjin 15500 USD |

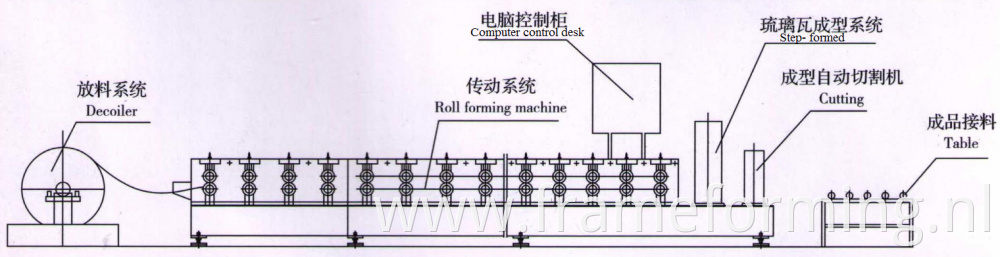

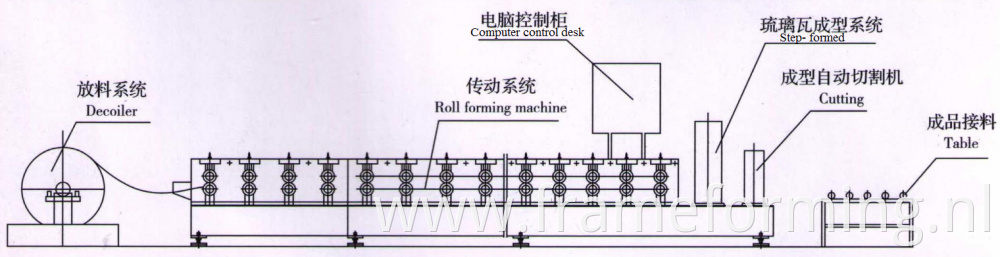

Metal Roofing Wall Sheet Panel Roll Forming Machine Production process

Uncoiling→Feeding material into machine→Roll forming→Measuring length→Step formed→ Auto cutting

→Products receiving

Components of Metal Roofing Wall Sheet Panel Roll Forming Machine production line

| No. | Name | Unit | Qty |

| 1 | Manual Decoiler | Set | 1 |

| 2 | Leveling beach by manual adjustment | set | 1 |

| 3 | Main forming machine | set | 1 |

| 4 | Shearing system with one cylinder | set | 1 |

| 4 | PLC control system | set | 1 |

| 5 | Hydraulic pump station | set | 1 |

| 6 | Motor drive | set | 1 |

| 7 | Output table | set | 1 |

| 5.5kw-0.8mm MACHINE |

| 1 | Machine working speed | 8 to 20 m/min |

| 2 | Frame middle plate with connect bar | 30 pieces |

| 3 | 350H Steel welded frame | One set |

| 4 | Frame thickness | 16 mm |

| 5 | Drive mode | Chain 1.0 |

| 6 | Chain gear | 195 diameter |

| 7 | Material of rollers 45#steel surface hard chromium plating |

| 8 | Material of shaft | 45#steel |

| 9 | Diameter of shaft | 80 mm |

| 10 | Roller station | 15 station |

| 11 | Main power | 5.5 kw |

| 12 | Motor brand | China mengniu |

| 13 | PLC brand | Delta |

| 14 | Hydraulic power | 3 kw |

| 15 | Two leveling rollers to make sure coil neat and clear |

| 16 | Give machine legs 2 pieces 1000mm*250mm |

| 17 | One holder two spring |

| 18 | Steel color of the protection bar, or you can specify |

| 19 | Supported material thickness from 0.2 to 0.8 mm |

| 20 | Working speed, adjustable. |

| 21 | yellow cutter and blue body or you can specify the color |

Maintenance methods and working principle of roll forming machine:

Circuit: Notice board cleaning, regularly clean up the dust of the electrical boxes, keep electrical boxes dry avoiding moisture.

Oil-way: Check whether there are oil leakages for every parts, timely handle. Prevent scratching on the piston rod and oil deterioration.

Equipment: check if there are abrasions on the transmission parts. check whether the grease fitting were blocked, and infuse butter.

Product Categories : Roofing Sheet Roll Forming Machine > Roof and Wall Panel Roll Forming Machine