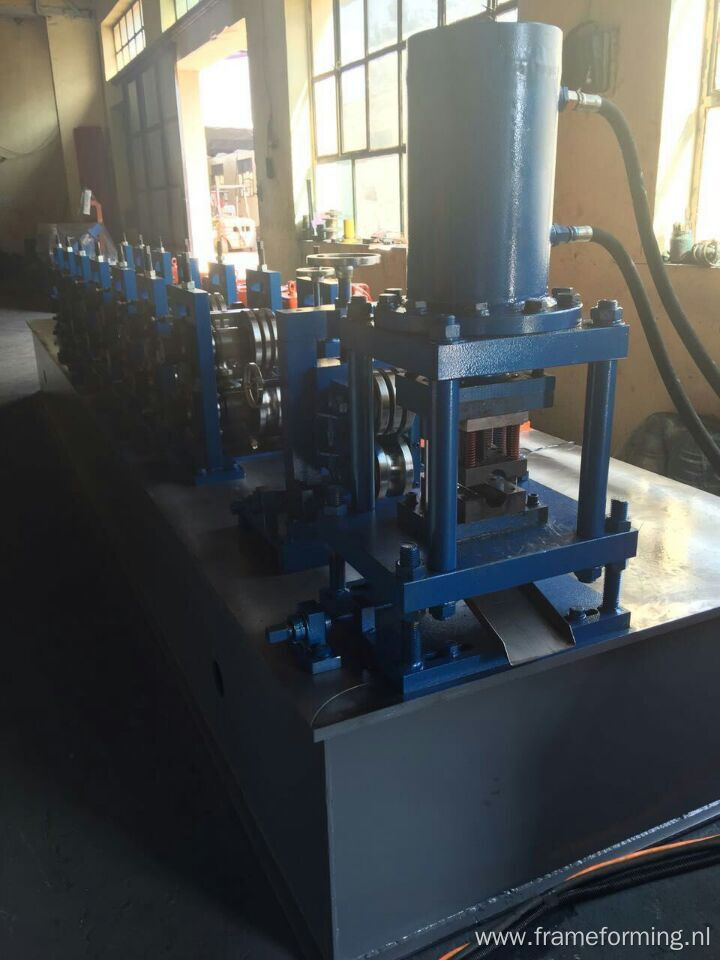

Sleet Bolt Roll Fomring Machine

Advantage of our Sleet Bolt Roll Fomring Machine :

1. Sleet Bolt Roll Fomring Machine is controlled by PLC control system ,during normal work,it will more security.

2. The basic of Steel Anchors Pipe Making Machine is guide column.

3.Transmission structure for the gear box. Each rack has a gear box molding can ensure that equipment over time, high-intensity running, and long service life.

Basic information of Sleet Bolt Roll Fomring Machine :

Process: decoiler--feeder--roll former--cutting and punch the line--run out table---necking

Decoiler

Usage: It is used to support the steel coil and uncoil it in a turntable way.

Passive uncoil pulled by roll forming system

Loading capacity: 3T

Uncoiling width: 300mm

Inner diameter: 450-550mm

Size: 4500х1800х1400mm

Weight : 5 tons

Voltage:380V/50HZ3Phase(as customer`s request)

Roller fixer : Vertical arch

Frame : middle plate welded

Memorial arch frame type

Frame thickness:25mm

Drive mode: Differential box

Material of rollers: GCr12MoV

Material of shafts: 45# steel with tempering

Diameter of shafts: φ70mm

Number of rollers : 11 rollers (5 Level, 6 Vertical)

Main power: 15kw

Cycloidal planetary gear speed reducer)

Speed: 25m/min

cutting and punch the line

Material of blades: Gcr12MoV quenched

Power supply : hydraulic power

Frame : Pillar style with rack & pinion system

Stroke switch : non-contact photoelectric switch

Components: It contains one set of cutting tools, one hydraulic tank and one cutter machine.

Hydraulic station

Hydraulic motor Power: 3kw

Hydraulic oil: 46#

Components: The system includes a set of hydraulic tank, a set of hydraulic oil pump, and two hydraulic pipes. And two sets of electromagnetism valves.

PLC station Feature:

1. Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.

2.Other electric element are Delta

3. Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety.

Necking machine

Mould Material : Gcr12MoV quenched

punching Power:5.5kw

Punching:42T

Punching the plate:

Mould material : Gcr12MoV quenched

punching power:4kw

Punching:25T

Final product for you reference:

1,Delivery date :45 working days

2,Payment terms: Payment: 30% T/T in advance and balance 70% after, Inspection confirmation before shipment.

Delivery: within 45 working days after receipt of deposit

Product Categories : Special Equipment For Industry