Metal Stud And Track Roll Former

Features of Metal Stud And Track Roll Former

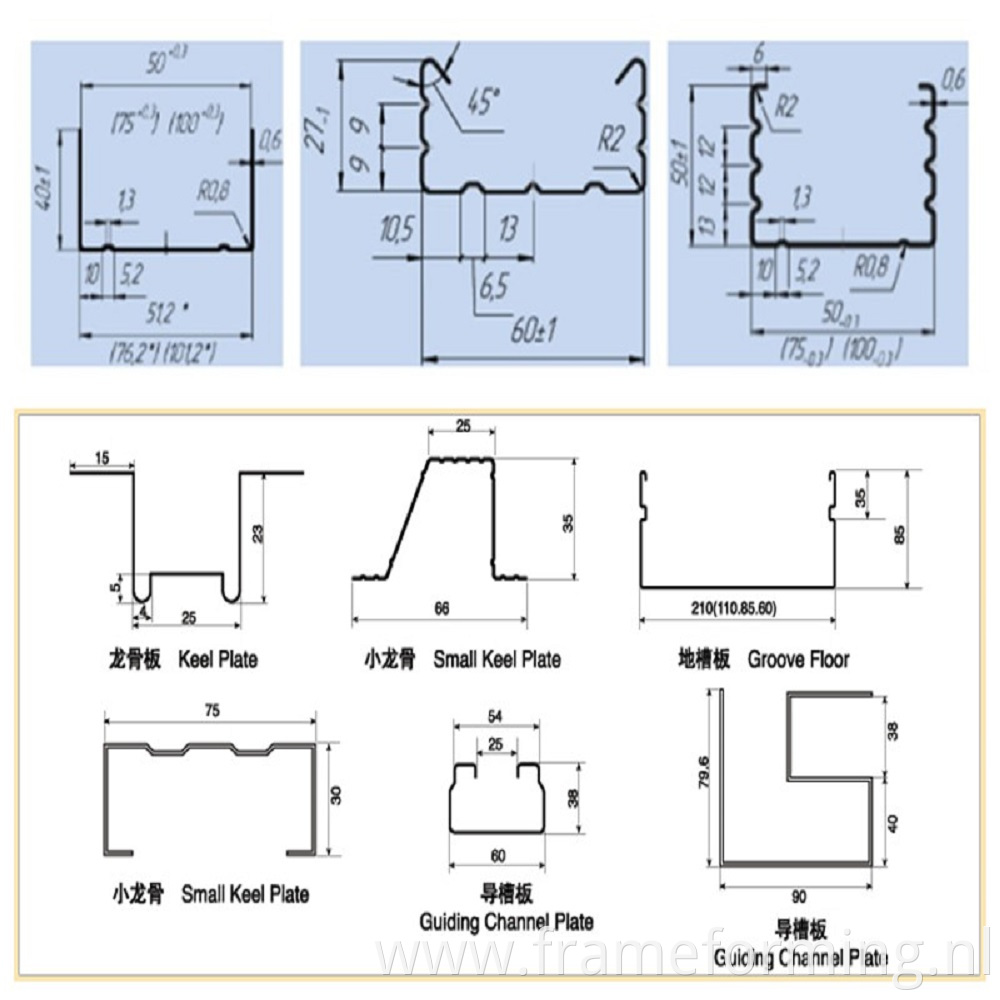

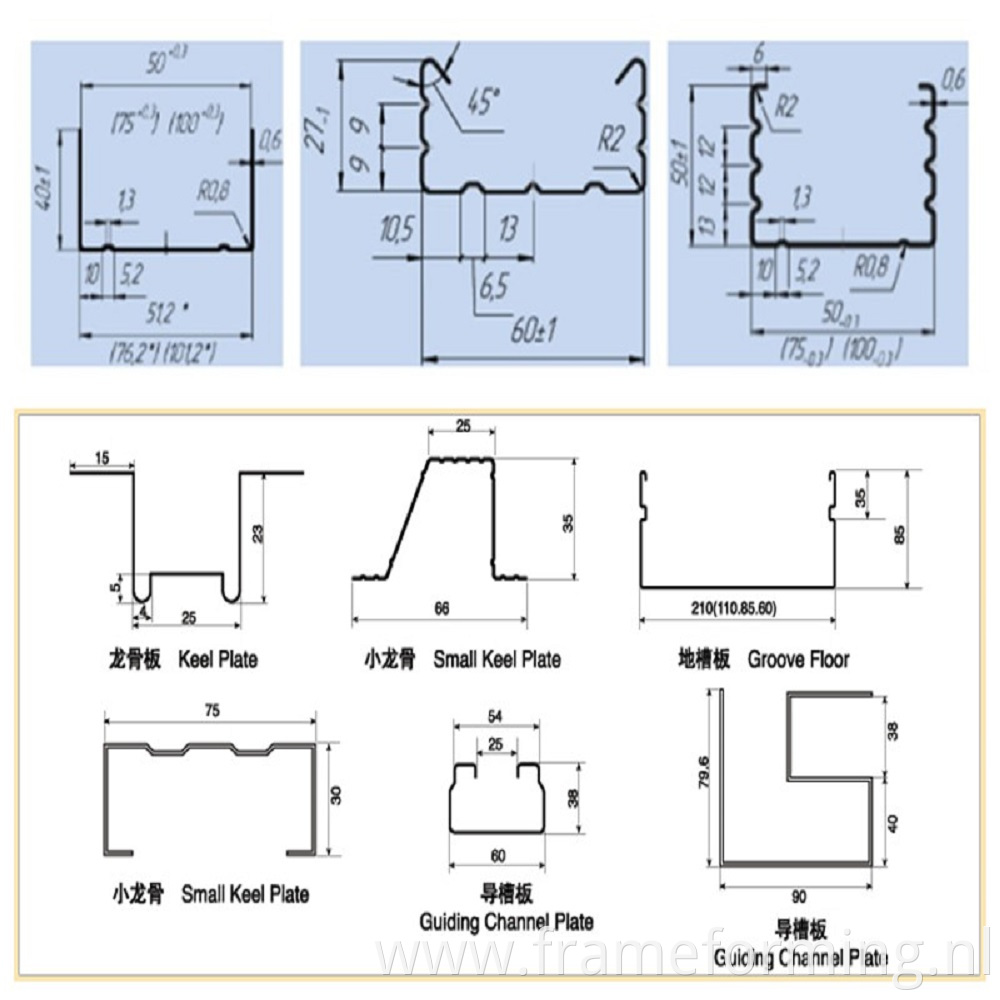

1. One machine either could be used to make U stud in various sizes

2. Able to make C stud in various sizes.

3. Easy to adjust sizes just by sizing in computer.

4. Machine is controlled by PLC station.

5.The machine will make the punching and cutting together, they can move when the machine working to conform the spped.

Main elements of Metal Stud And Track Roll Former

1.Decoiler

2.main Roll Forming Machine

3.punching maching(as customer's need)

4.Cutting machine (normal cutting and flying track cutting saw)(as customer`s need choose one set)

5.PLC control

6. Counter

7.hydraulic station

8. receiving table

Some main parameters of Metal Stud And Track Roll Former

1.Working efficiency:25-120m/min

2.Processing material: GI

3.Material hardness: 550MPA-350MPA

4.Thickness of material: 0.3-1.2mm

5.Width of material: as you need

6.Un-coiler system: 1.5 Ton decoiler (Manual Decoiler, electric decoiler , hydraulic decoiler)

7.Number of rollers: 10 rollers

8.Metal Stud And Track Roll Former Roller fixer: guide column

9.Roller material: Gcr12 MoV quenched

10.Material of shaft: 45# steel

11.Diameter of shaft: 40mm

12. Main power: 5.5KW

13.Hydraulic power: 3KW

14.Hydraulic pressure: 20Mpa

15.Blade material:Gcr12 MoV quenched

16.Voltage: 380V, 50HZ, 3phase (adjustable by customer)

17.DMetal Stud And Track Roll Former Frame: 25mm

18.Drive : gear, chain or case of different speeds(as customer`s demand)

19.Dry Wall Metal Stud And Track Machine Punching mould: each type one set

20.Punching machine: Gcr12 MoV quenched

21.Metal Stud And Track Roll Former Control system: Delta of Taiwan.

22.Metal Stud And Track Roll Formercolor: yellow or blue

23.Lenth: 3000*800*1400mm

Payment: 30% T/T in advance and balance 70% after inspection confirmation before shipment.

1. One year, and we will provide the technical support for the whole life.

2. Training: the buyer should charge of visa, return ticket, food and accommodation overseas and

USD50/person/day for salary.

3. Need one technician.

4. Training time: one week (contains the time of installation and adjustment)

Product Categories : C/U/ Channel & T Bar Roll Forming Machine > Drywall Profile Roll Forming Machine