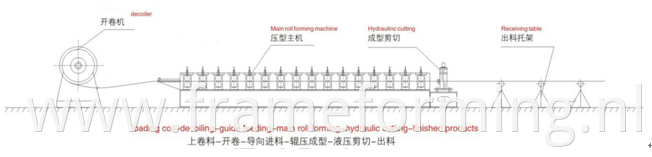

| Configurations | manual decoiler, guiding platform, main machine of roll forming, cutting device, electric motor, hydraulic station, Delta PLC control system, run out table |

| |

| Material | Raw material | Galvanized |

| Thickness | 0.3-0.8 mm |

| |

| Manual decoiler | Inner Diameter | 450-550mm |

| Outer Diameter | max 1500mm |

| Max Coil width | 500mm |

| Capacity | 3T |

| |

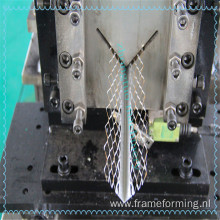

| Main Forming Machine | Forming steps | 12 rollers |

| Shaft diameter | 40Cr steel with quenched treatment, precision machined, outer diameter: 40mm |

| Design type | Guide column |

| Machine frame | Memorial arch |

| roller material | bearing steel with quenched treatment |

| shaft material | 45# steel with tempering |

| Work speed | 20-60m/min |

| Transport | reduction gearbox transmission |

| Changing size methods | Completely changing the mold linear system |

| Structure | independent stand |

| Power of main machine | 7.5 kw |

| Type of cutting and punching | Hydraulic |

| Cutting tolerance | ±1mm |

| Blade and punching material | GCr12MoV quenching treatment 58-60° |

| Cutter quantity | 1 set |

| Working pressure | 20MPA |

| Cutting system | Hydraulic servo tracking cutting | the machine is with servo tracking cutting, the cutting knife can move automaticly with the speed of the machine. so that, the tracking cutting can keep same speed with the main forming speed, and cut the finished products without any stopping. |

| 2. Automatic tracking cutting | No. | Name | Size and mode | number | note | | 1 | base frame | 100*100*6 | 1 | | | 2 | Control station | | 1 | Include switch button | | 3 | Hydraulic station | 4kw | 1 | | | 4 | Oil pump | 63*80*80 | 1 | | | 5 | Cooling device | 35Hz | 1 | | | 6 | Sensor | Npu | 2 | | | 7 | Encoder | 600 | 1 | Omron | | 8 | tachometric wheel | | 2 | | | 9 | Servo motor | 3.9kw | 1 | GSK | | 10 | Mold | Mulfan1 | 4 | | | 11 | Lead screw | Sfu4020-1230 | 1 | Taiwan | | 12 | Guide | HG35-2000 | 2 | | | 13 | Slider | HGH35cA | 4 | | | 14 | Coupling | | 4 | | |

| |

| Control Device | PLC Control | Speed regulation control cabinet |

| PLC language | As required |

| Touch screen | Delta |

| Function | Automatic length and quantity measurement |

| |

| Other Spare part | Weight | About 8.0 ton |

| Dimension | 6800*1800*1500 (mm) L x W x H |

| Main body color | As required |

| Voltage | 380v, 50Hz,3 phase(or as required) |

| Spare cutting blade | One piece for one size |