cold roll forming line is also called aluminum roof machine or else roof machine. Because its frame is guide pillar, More beautiful and more stable when running production. This frame machine belong to a kind of high configuration design. And it is with two hydraulic cylinders and pillar frame on the hydraulic part, so rather easy for up and down, and in favor of promoting its speed. no hard to damage for the slideway and cutting blade.

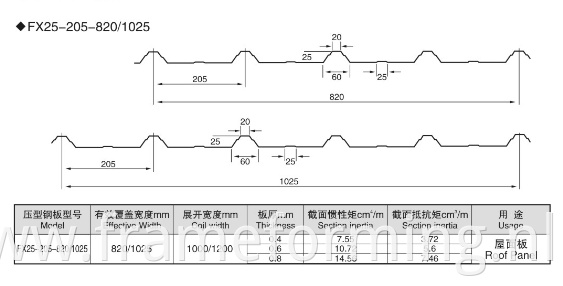

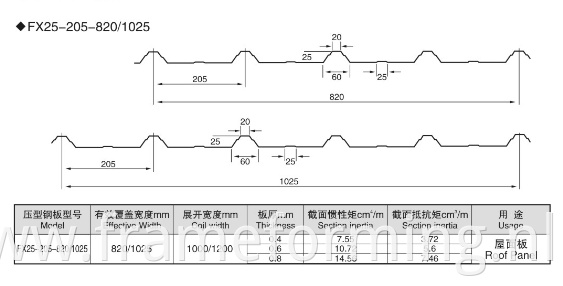

Draiwings profile of cold roof tile:

Main specificaton of cold roll forming line:

UNCOILER:

Type of Uncoiler: Manual

Material of coil: Color Steel Coil, galvanized coil, aluminium coil

Thickness of sheet: 0.3mm-0.8mm

Width of coil: 1200mm

Weight of coil: ≤ 5 mt

aluminum roof machine:

Type of Forming: Single layer forming

Stands of Forming: 16 stations

Diameter OF shaft: 70mm – 80mm

Thickness of Chromic plating of roller surface:0.05mm –0.06mm

Speed of Forming:2m-4m/minute

Required Power: 4.0-7.0kw

Size of cold roll forming line: 7500mm x 1500mm x1200mm

Weight of Forming Machine: 6-8 Tons

Rollers of aluminum roof machine are made of the bearing steel Cr15 to strike, distressing to annealing, quenching, tempering, and Parkerizing,

such heat treatment process. The surface hardness reached HRC60 degree. All the rollers are made by the CNC machine tools, which guarantees the accuracy

of the roller`s sizes and prolongs its working life.

HYDRAULIC PRESS & CUTTER:

Hydraulic cutter Shearing pressure: 10-12MPa

Power: 5.5KW

CONTORL CABINET

· PLC Panasonic (from Japan)

· Touch screen Hitech (from japan)

Pictures of cold roll forming line:

Product Categories : Roofing Sheet Roll Forming Machine > Roof and Wall Panel Roll Forming Machine