Standing seam roll former

Support you money !! Support you service !! Support you technology !!

PLC control system !! Hydraulic cutting system !! Mult-language conversion system !!

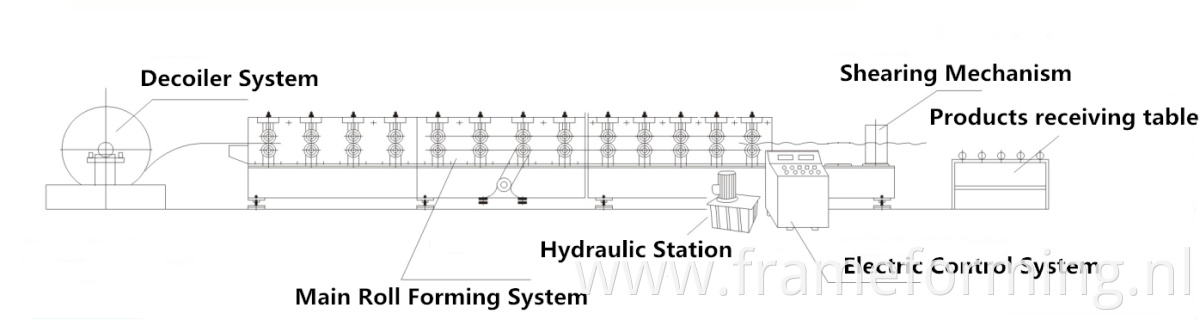

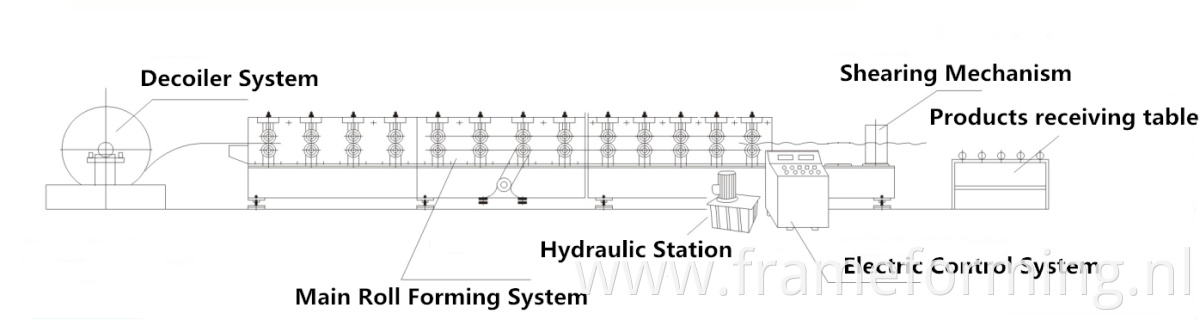

Standing seam roll former Uncoiler System:

Usage: It is used to support the steel coil and uncoil it in a turnable way.

Passive uncoil pulled by roll forming system

Loading capacity: 5T

Uncoiling width: 1500mm

Inner diameter: 450-550mm

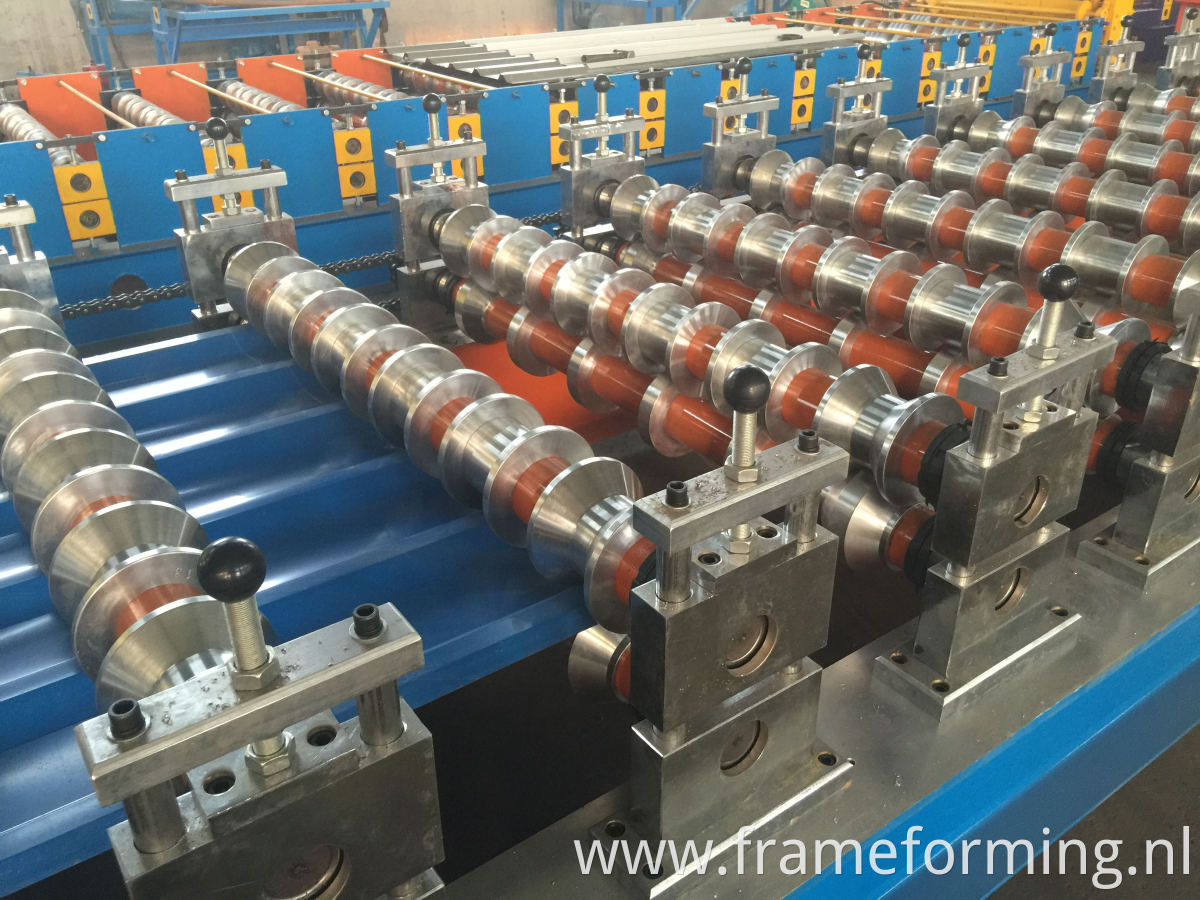

Standing seam roll former Main Roll Forming System:

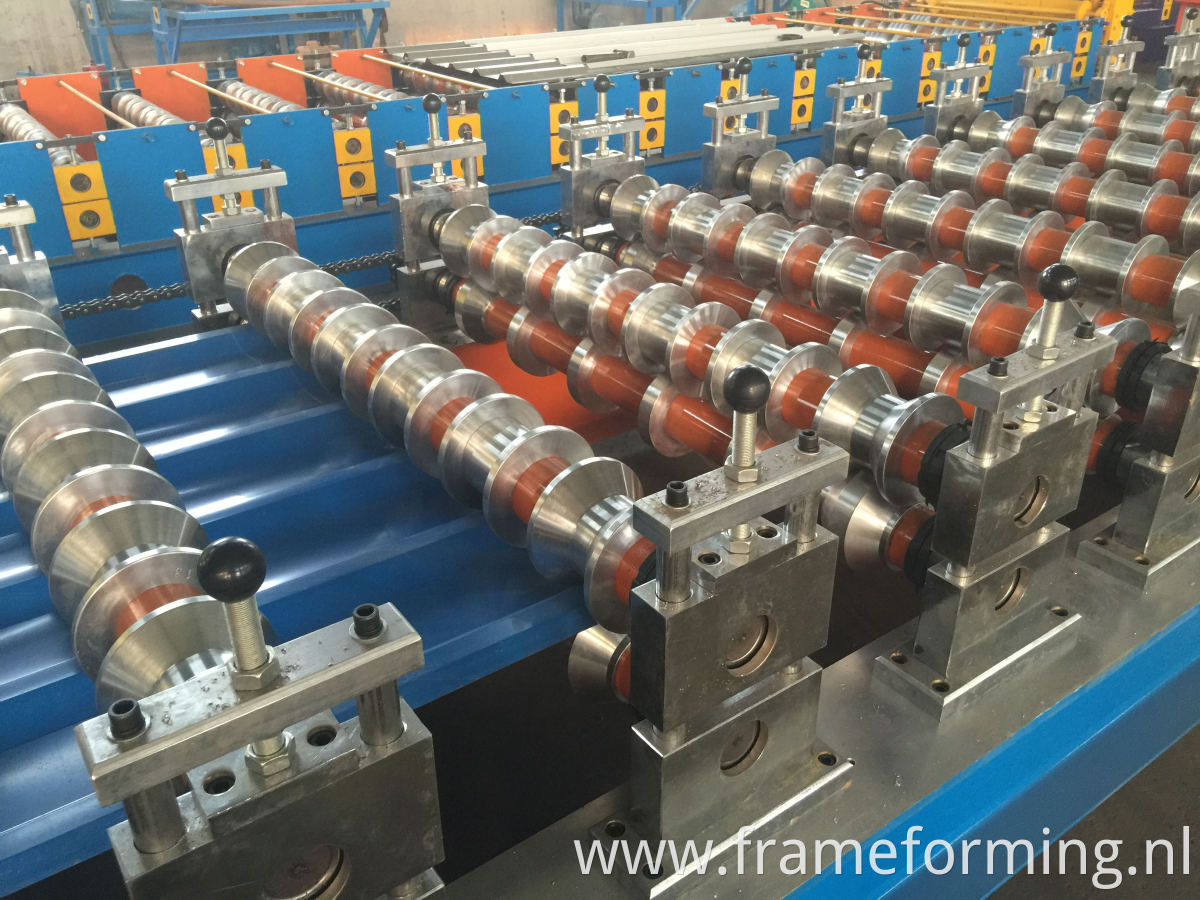

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission,roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Length of the main part: about 6500х1450х1500

Weight of main part: 3.8 tons

Voltage: 380v 50hz 3 phase

Roller fixer: middle plate

Frame: 350 H steel welded

Drive mode: chain

Material of rollers:45# steel, surface hard chromium plating.

Material of shafts: 45# steel

Diameter of shafts: φ80mm

Number of rollers: 13 rollers

Main power: 5.5kw

Standing seam roll former Shearing Mechanism:

Feature : Ensure stability, precision and cutting speed

Function : Automatic cutting controlled by PLC

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: Cr12 quenched

Power supply : hydraulic power

Components:It contains one set of blade, one hydraulic tank and one cutter machine.

Standing seam roll former Hydraulic Station:

It is controlled by gear pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

Power: 3kw

Hydraulic oil: 46#

Components: The system includes a set of hydraulic tank , a set of hydraulic oil pump, four hydraulic pipes.and two sets of electromagnetism valves.

Standing seam roll former Electric Control System:

1. Adopted PLC , frequency converter , Delta touch screen from Taiwan to ensure high speed with stability, precision and lifetime.

2. Other electric element are Panasonic.

Standing seam roll former Our Service:

a. If buyers visit our factory and check the machine, we will teach you how to install and use the Roll Forming Machine for sale , and also train your workers/technician face to face.

b. Without visiting, we will send you user manual and video to teach you to install and operate.

c. If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary things.

d. If there is any problem found of steel roof sheet roll forming machinery, we will repair roll forming machine for sale for free in one year.

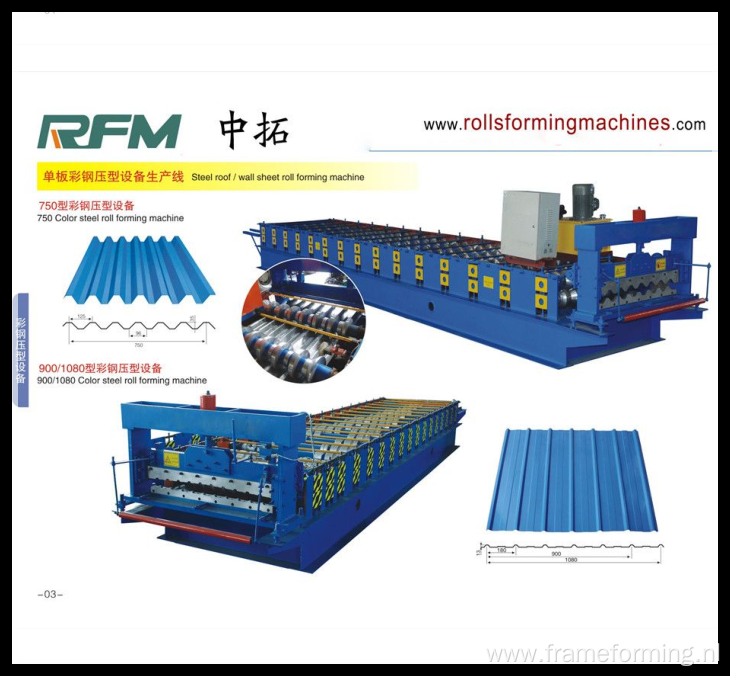

Product Categories : Roofing Sheet Roll Forming Machine > Roof and Wall Panel Roll Forming Machine