steel frame CZU purline machine CZU channel Roll Forming Machine

China Pre-Cutting Hydraulic Steel Stud C/Z Purlin Machine is a machine can produce many sizes,Generally,there are three types of machine, c purlin machine, z Purlin Roll Forming Machine, C Z Section Steel Purlin Machine. The Web width can be 60-300mm Flange height can be 30-80, it is adjustable from min to max. The size of holes can be design by customers.

This China Pre-Cutting Hydraulic Steel Stud C/Z Purlin Machine consists of uncoiler,feeding and straightening,punching and cutting part, main roll forming part,cutting device and runout table.

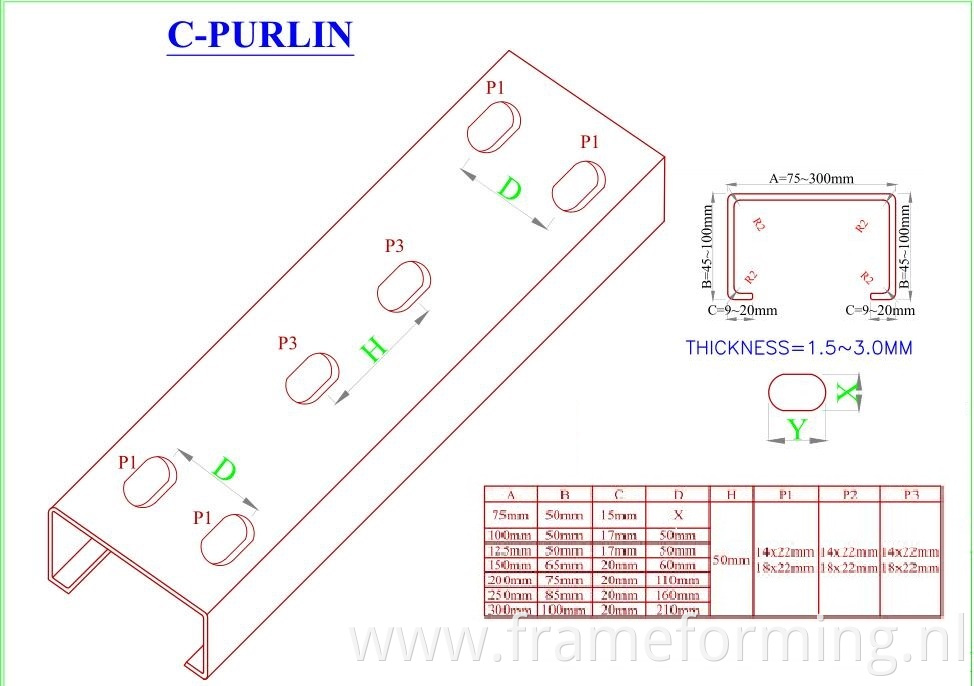

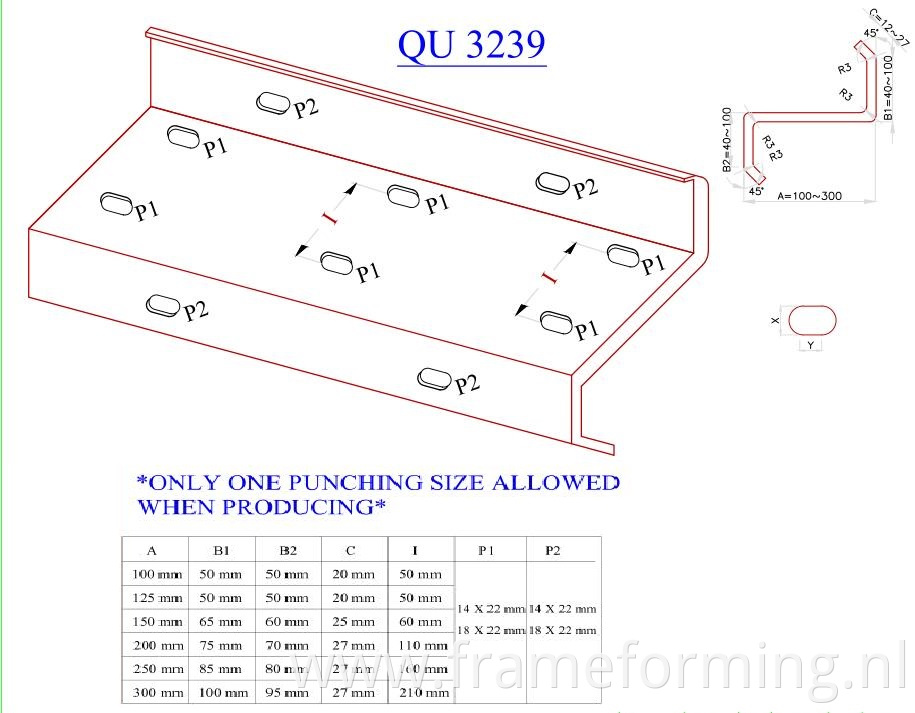

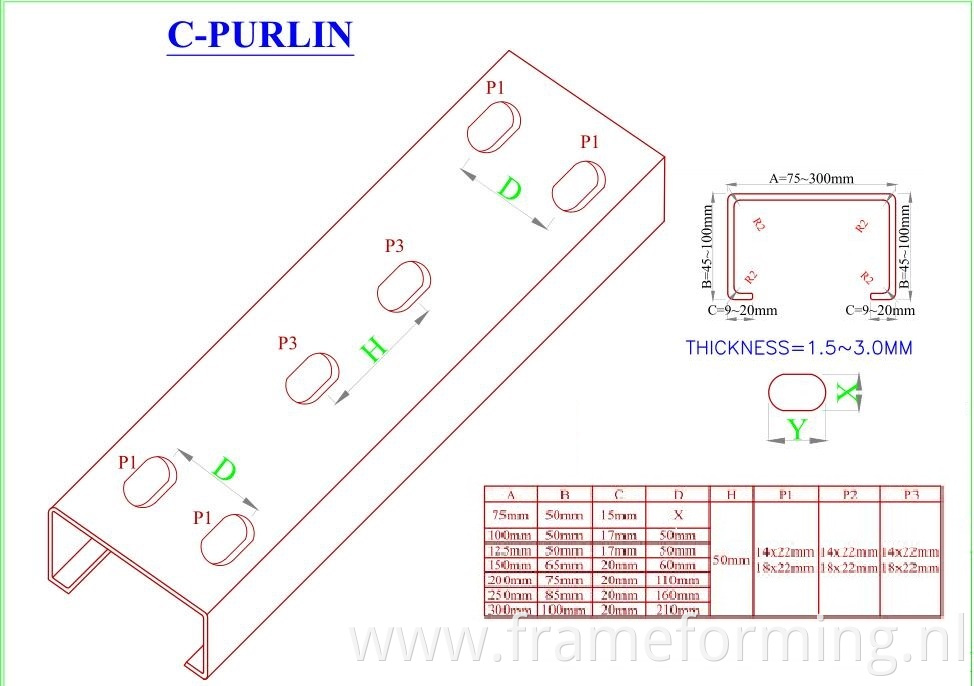

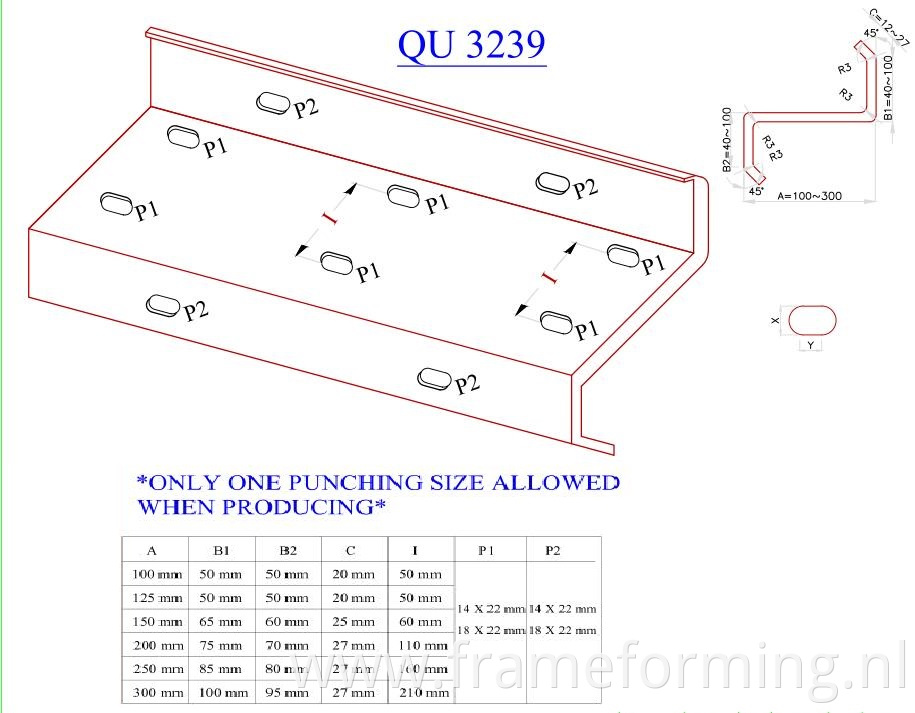

The size we can do:

Some pictures for you reference:

The Parameters of Pre-Cutting Hydraulic Steel Stud C/Z Purlin Machine

Manual un-coiler System

Loading capacity: 5T;

Uncoiling width: 500mm ;

Inner diameter: 450-550mm

Entry Beach

Specification:Usage: Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

Shearing Mechanism and punching (include cutting tools, hydraulic tank, cutter machine)

1)Feature : Ensure stability, precision and cutting speed; Function : Automatic cutting controlled by PLC; Material of blades: Gcr12MoV quenched;

2)Power supply : hydraulic power;

Main Roll Forming System for Pre-Cutting Hydraulic Steel Stud C/Z Purlin Machine

1)Number of forming steps:12stations;

2)Shaft material:45# steel Outer diameter:80mm ;

3) Roller Material:Cr12MoV ;

4)Transport: chain ;

5)Forming speed:5-12m/min ;

6)Motor:15kw ;

7)Voltage:380v,50Hz,3 phase ;

8)Frame : middle plate welded ;

9)Dimensions:12000mm*1800mm*1600mm ;

10)Weight of machine: about 9ton

Hydraulic Station

1)Hydraulic motor Power: 5.5kw ;

2)Hydraulic oil: 46# (include a set of hydraulic tank , a set of hydraulic oil pump,two hydraulic pipes and two sets of electromagnetism valves )

Electric Control System

1.Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.

2.Other electric element are Delta; 3.Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety.

Payment method:

Method 1:

Payment of the contract with following schedule:

- 30%: The payment shall pay by T/T the down payment to the Seller within 15 days after the signature of the Contract. The Contract then comes into effect.

- 70%: The buyer shall pay to seller the remaining 70% of total contract amount before the seller`s ship the machine to XINGANG, CHINA.

Method 2

L/C is also acceptable.

Installation, Commissioning, Test and Training

1. The engineers from the Seller shall supervise the installation on site and fulfill the commissioning. They should start off within 10 days after they get the information from the Buyer.

2. The Buyer signs in the Certificate of Acceptance.

3. The Seller trains the operators of the Buyer during the commissioning

4. Commissioning: about 1 engineers in 7 days.

5. The Buyer shall pay for the international air tickets and the local, such as board and lodging, daily transportation, communication,Insurance, etc. The Buyer shall pay USD 80 /day /person to the Seller for the commissioning.

6. The Buyer shall prepare an interpreter for better communication between the two sides.

Below are some new machines just finished, the machine pictures, please check it:

Product Categories : C/Z/U Purline Roll Forming Machine > Purline Roll Forming Machine