automatic C/Z purlin forming machine

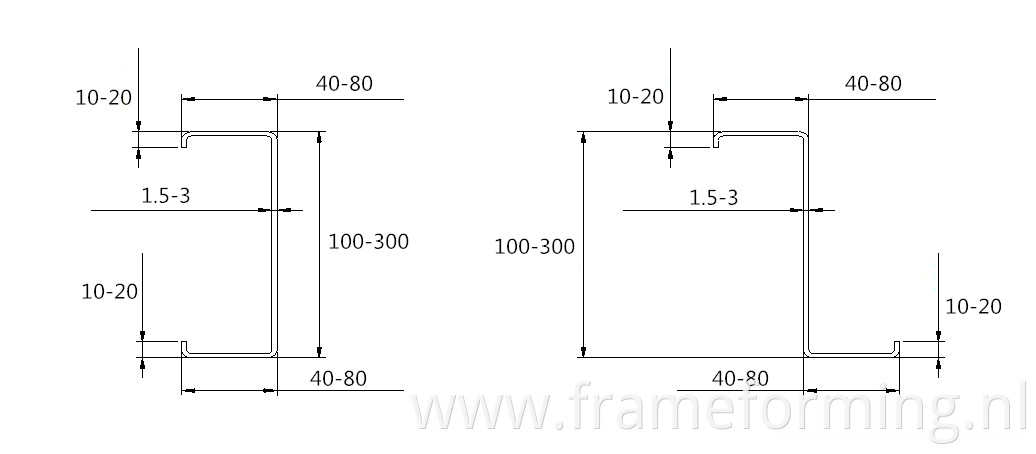

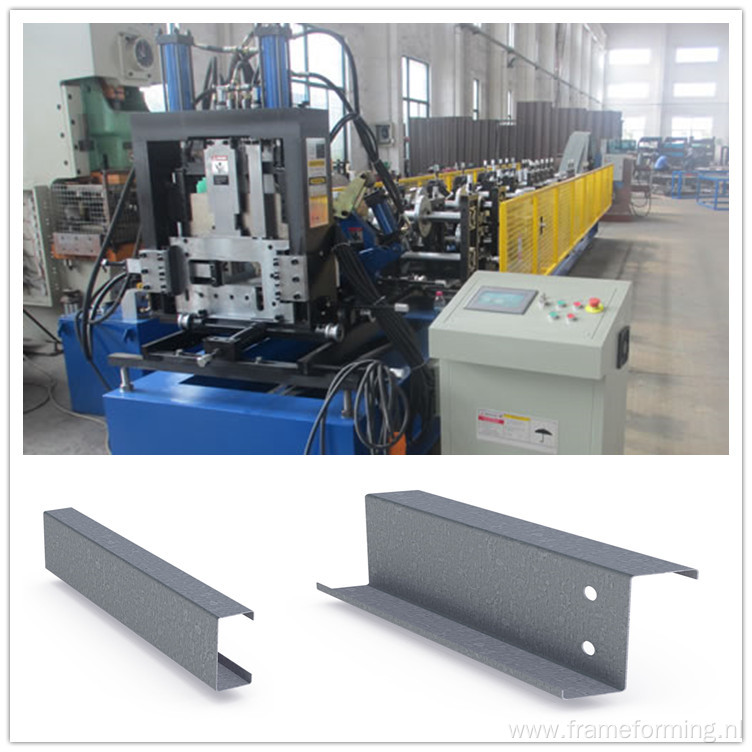

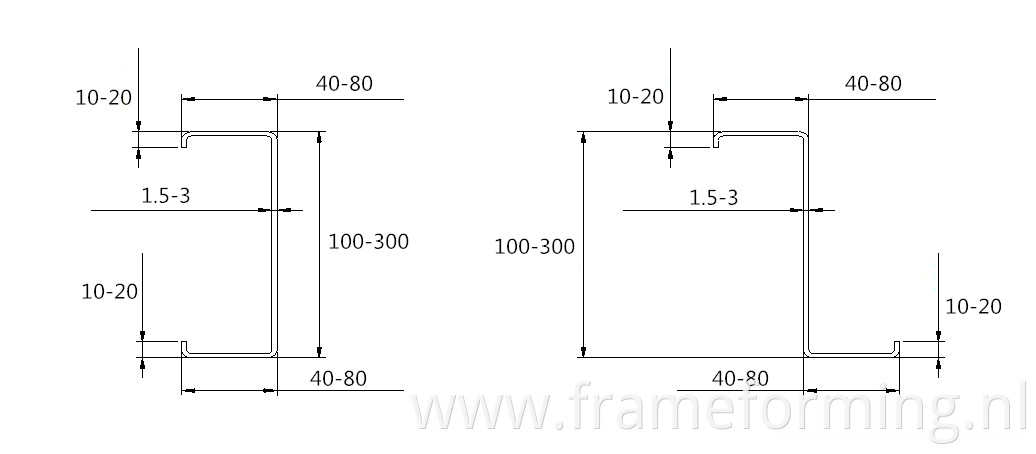

This automatic C/Z purlin forming machine can produce C Z purlin .You can set on the PLC for different sizes. When you want to get Z purlin, rotate the rollers manually.

Features of automatic C/Z purlin forming machine:

1. It offers a rapid change rollformer for allowing the operator to select a flange height change in minutes and not hours.

2. The web width change in an infinite range from 100mm up to 300mm fully automatic.

3. It supports produce purlin in pre-painted, in galvanized and also the use of Hot Rolled steel.

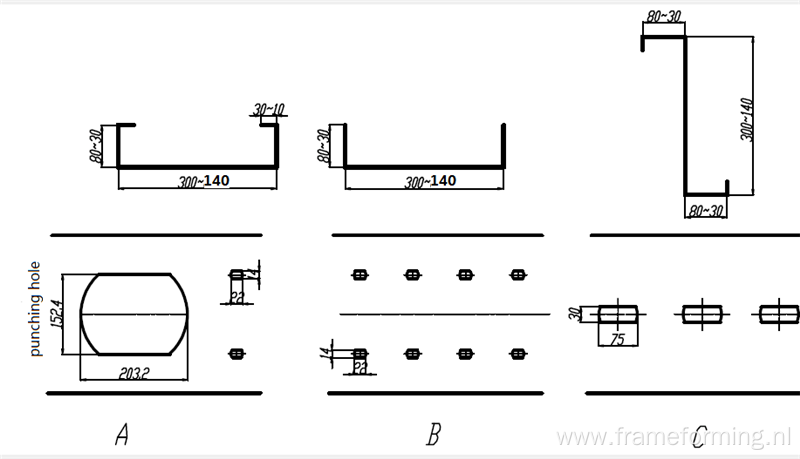

4. High accuracy with punching and high speed from uncoilers, as well as a wide range of hole punching systems for inline web and flange hole placement with high accuracy.

5. Automation of gapping the roll tooling for different thicknesses can be added so that your operator does not have to adjust the top shaft for material thickness changes.

Pls refer to the videos

Video:https://www.youtube.com/watch?v=-bdb6lmPc8A

https://www.youtube.com/watch?v=PdtOC3lDuZo

https://www.youtube.com/watch?v=F2_g7ZVsWhY

technical parameters of automatic C/Z purlin forming machine

| It is used to support the steel coil and uncoil it in a turntable way. Passive uncoil pulled by roll forming system. Capacity: 5 Tons Loading width: Max 550 mm Valid expanding range for coil inner diameter: 450-610 mm |

| Adjustable center of the forming rollers and of sufficient length to prevent lateral movement of the strip on its entry to leveling system. Feeding type: Adjustable Feeding width range:150-550 mm Entrance and guide roller: Diameter is¢80 mm Roller material: SAE 1045, HRC 48-52 surface with chrome |

| Machine base frame adopt H beam welding steel. In the main Roll Forming Machine have 2 buttons for urgency stop if happen any malfunction. Machine adopt iron cast as station to make machine in strong. To avoid accidents, all of drive part adopt protect cover. Drive type: Chain Roller station: 18 groups Working speed: 8-12 m/minute Main motor power: 18.5 kw Width adjust motor power: 4.5 kw (1.5 kw*3 sets) Voltage / Frequency / Phase: 380 V 50 Hz 3 Phase Roller material: Gcr 15 steel and quench treatment hardness HRC 55-58, chrome coated 0.05 mm The width of the profile can be automatic adjusted by the control computer and the last 10 roller stations can be manual overturned to make C or Z purlin. |

| The hydraulic cutting machine with good compression performance, good flatness, automatic fixed-length cutting, high degree of automation. Cutting blade: Cr 12 mov Cutting tolerance: 12 m +/- 1.5 mm Cutting type: Hydraulic cutting after forming Auto cutting when reach the length set on the computer. The width and height of cutting blade can be manual adjusted . |

| Table for reception of the cut profiles, there are rollers on the table to unload the cut profile freely. Frame: Welding by steel angle Diameter of support rollers: 55 mm Roller material: ASTM 1045 with chrome Table size: About 2.0 *0.6 * 0.9 m (L*W*H) Table color: Blue or base on customer request |

| It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank , the pump drive the cutter machine to begin the punching and cutting job. Hydraulic motor : 7.5 kw Hydraulic oil: 46# 60 L Components: The system includes a set of hydraulic tank , a set of hydraulic oil pump, three hydraulic pipes and three sets of electromagnetism valves. |

| The PLC (Programmable Logic Controller) powered by the software that controls the automation of the processes of the forming, cutting and punching. It adopt the latest technology that allow the operator enter all data through a touch screen quickly and reliably to meet a predetermined production. Voltage/ Frequency / Phase: 380 V 50 Hz 3 Phase Automatic length measurement Automatic quantity measurement Length Tolerance: 6 m ±1.5 mm Length inaccuracy can be amended easily. Language: English and Chinese Control panel: Button-type and touch screen |

FAQ:

1.How to get a quotation of automatic C/Z purlin forming machine?

Give me the profile drawing and thickness for the c purlin,this is the important.

Other spicific requirements is welcome,such as the speed,power and voltage you want.

2. Terms of payment:

30% T/T, Balance to be paid before shipping after inspection.Also we accept the payment L/C, O/A , D/P.

4. What is your after-sale service?

automatic C/Z purlin forming machine's warranty period is 24 months,if the broken parts can't be repaired,we can send new to replace for free,but you need to pay the express cost yourself.we supply the technical support for the whole life of the equipment.

6. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour), then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

Product Categories : C/Z/U Purline Roll Forming Machine > Purline Roll Forming Machine